Recycling method for waste silicone rubber material by radiation method

A silicone rubber, recycling technology, applied in recycling technology, chemical instruments and methods, plastic recycling, etc., can solve the problems of environmental pollution, high energy consumption, etc., reduce production costs, easy to operate, solve space occupation and pollution environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

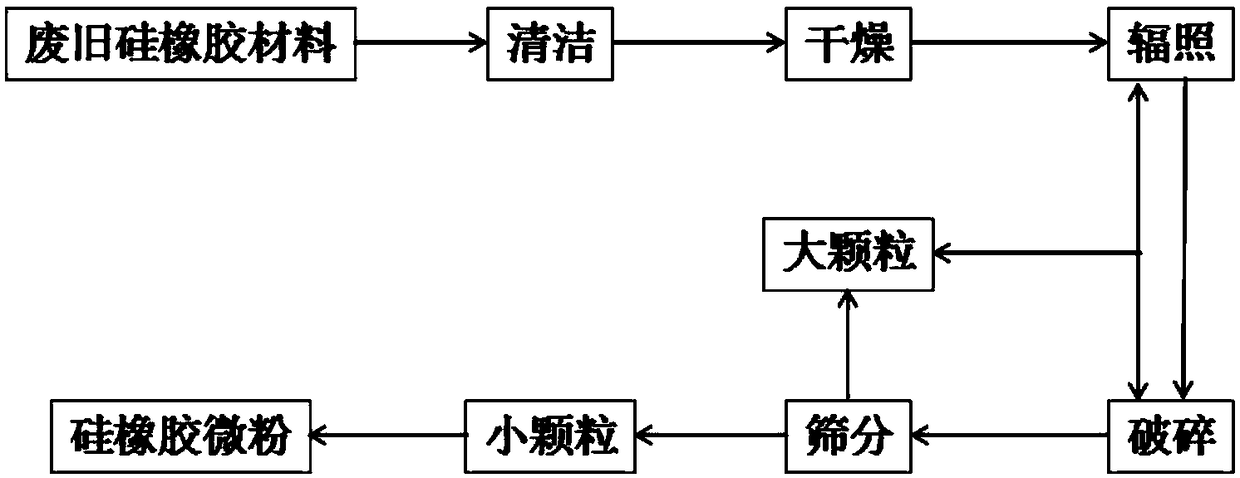

[0022] A method for reusing waste silicone rubber materials by radiation method, including the following steps:

[0023] Step 1: Clean and dry the recovered solid rubber scraps of vulcanized silicone rubber;

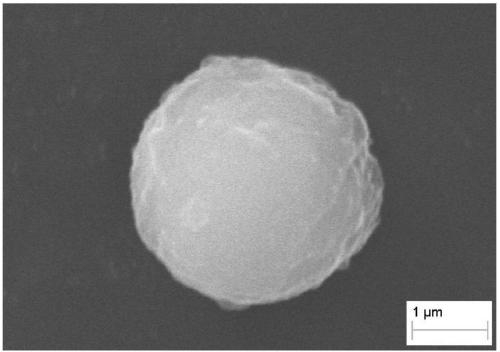

[0024] Step 2. Spread the dried solid rubber scraps of vulcanized silicone rubber on a stainless steel stand and place them in the cobalt source gamma irradiation field to make the accumulated absorbed dose reach 1.0MGy, and the material will be removed during the irradiation Turn it once to ensure that the bottom material can receive enough radiation of the accumulated absorbed dose, take it out and put it in an open mill for repeated crushing for 30 minutes, and properly sieving to obtain micron-sized silicon rubber powder.

Embodiment 2

[0026] A method for reusing waste silicone rubber materials by radiation method, including the following steps:

[0027] Step 1. Clean and dry the recycled silicone rubber foam;

[0028] Step 2. Spread the dried silicone rubber foam on a stainless steel stand, place it in an electron accelerator and irradiate it to make the cumulative absorbed dose reach 1.0MGy, and turn the material three times during the irradiation process, take it out and put it in It is crushed in a planetary ball mill for 20 minutes and sieved appropriately to obtain micron-sized silicon rubber powder.

Embodiment 3

[0030] A method for reusing waste silicone rubber materials by radiation method, including the following steps:

[0031] Step 1: Clean and dry the recycled solid rubber scraps of vulcanized silicone rubber, waste silicone rubber foam, and raw silicone rubber to obtain a mixture;

[0032] Step 2. Spread the dried mixture on a stainless steel stand, place it in the cobalt source gamma irradiation field to make the accumulated absorbed dose reach 1.2MGy, and turn the material over once during the irradiation process and take it out Put it into a planetary ball mill and pulverize for 10 minutes, and sieve appropriately to obtain micron-sized silicon rubber powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com