Environmental-friendly flame-retardant sound insulating material as well as preparation method and application thereof

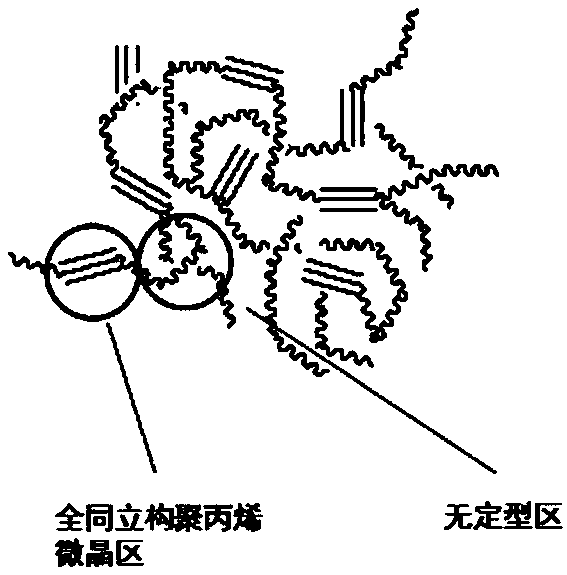

A sound insulation material and an environmentally friendly technology, applied in the field of polymer-based sound insulation materials and their preparation, can solve the problems that the sound insulation material does not have flame retardant properties, the prohibited and restricted ophthalmic substances exceed the standard, and the human body is harmed, so as to improve the VOC volatilization, The effect of excellent environmental protection performance and strong ability to eat powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

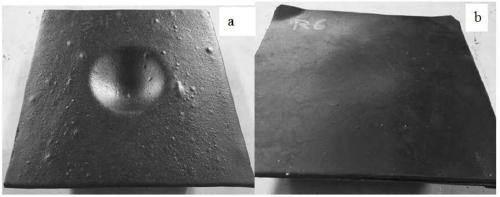

Examples

Embodiment 1

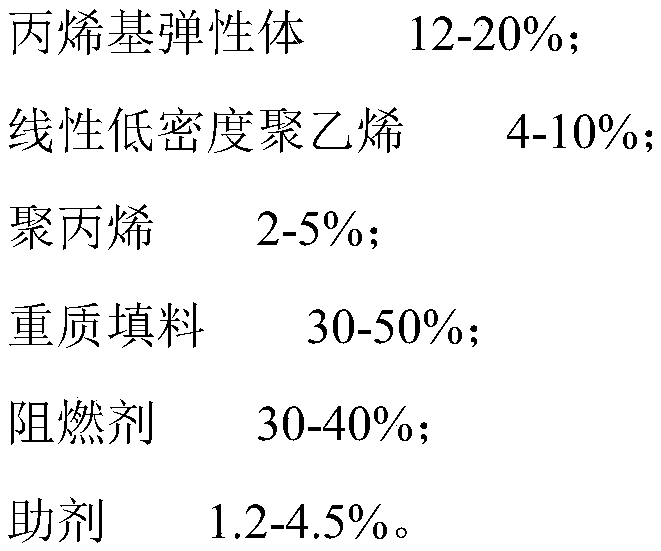

[0033] An environmentally friendly flame-retardant and sound-insulating material, comprising the following components in terms of mass percentages: 18 parts of propylene-based elastomer, 5 parts of linear low-density polyethylene, 2 parts of random copolymerized polypropylene, 35 parts of heavy filler, and a flame retardant 40 parts, 2 parts of auxiliary agent. Among them, the heavy filler is barium sulfate, and the flame retardant is magnesium hydroxide; the auxiliary agent includes the following components in mass percentage: 0.5 parts of rubber oil, 1 part of stearic acid, and 0.5 parts of silane coupling agent.

[0034] The preparation method of the above-mentioned environmentally friendly flame-retardant sound-insulating material comprises the following steps:

[0035] (1) Put each component into the internal mixer in proportion and initially melt and mix at 150-170° C., and then add the initially melt-mixed melt to a twin-screw extruder through a cone double feeder to fu...

Embodiment 2

[0039] An environmentally friendly flame-retardant and sound-insulating material, comprising the following components by mass percentage: 12 parts of propylene-based elastomer, 10 parts of linear low-density polyethylene, 3 parts of block copolymer polypropylene, 45 parts of heavy filler, and flame retardant 30 parts, 3 parts of auxiliary agent. Among them, the heavy filler is iron powder, and the flame retardant is ammonium polyphosphate; the auxiliary agent includes the following components in mass percentage: 1 part of rubber oil, 1 part of stearic acid, and 1 part of silane coupling agent.

[0040] The preparation method of the above-mentioned environmentally friendly flame-retardant sound-insulating material comprises the following steps:

[0041] (1) Put each component into the internal mixer in proportion and initially melt and mix at 150-170° C., and then add the initially melt-mixed melt to a twin-screw extruder through a cone double feeder to further melt and mix eve...

Embodiment 3

[0045] An environmentally friendly flame-retardant and sound-insulating material, comprising the following components in terms of mass percentages: 20 parts of propylene-based elastomer, 4 parts of linear low-density polyethylene, 2 parts of random copolymerized polypropylene, 39 parts of heavy filler, and a flame retardant 35 parts, 2.5 parts of auxiliary agent. Among them, the heavy filler is calcium carbonate, and the flame retardant is aluminum hypophosphite; the auxiliary agent includes the following components in mass percentage: 1 part of rubber oil, 1 part of stearic acid, and 0.5 part of silane coupling agent.

[0046] The preparation method of the above-mentioned environmentally friendly flame-retardant sound-insulating material comprises the following steps:

[0047] (1) Put each component into the internal mixer in proportion and initially melt and mix at 150-170° C., and then add the initially melt-mixed melt to a twin-screw extruder through a cone double feeder t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com