Removal agent of sulfur-containing odorous gas of thickened oil thermal production well and preparation method of removal agent

A technology for thermal recovery and removal of heavy oil, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of decreased chemical effect, accelerated decomposition of triazines, etc., and achieves low pH value and stable performance. Strong, low-dose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

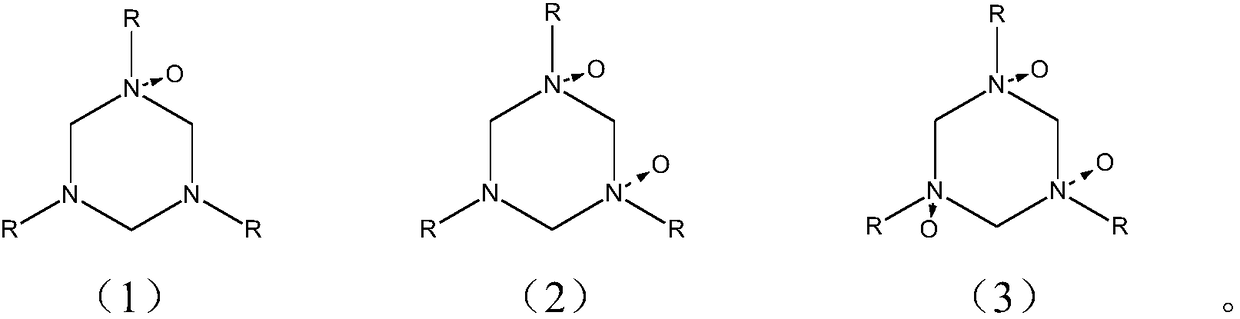

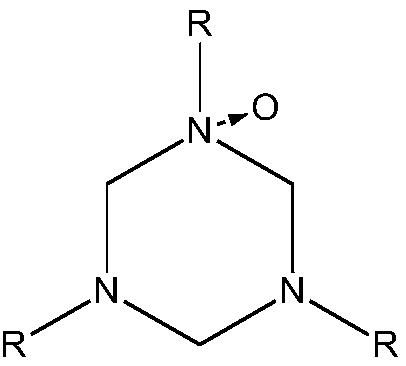

Method used

Image

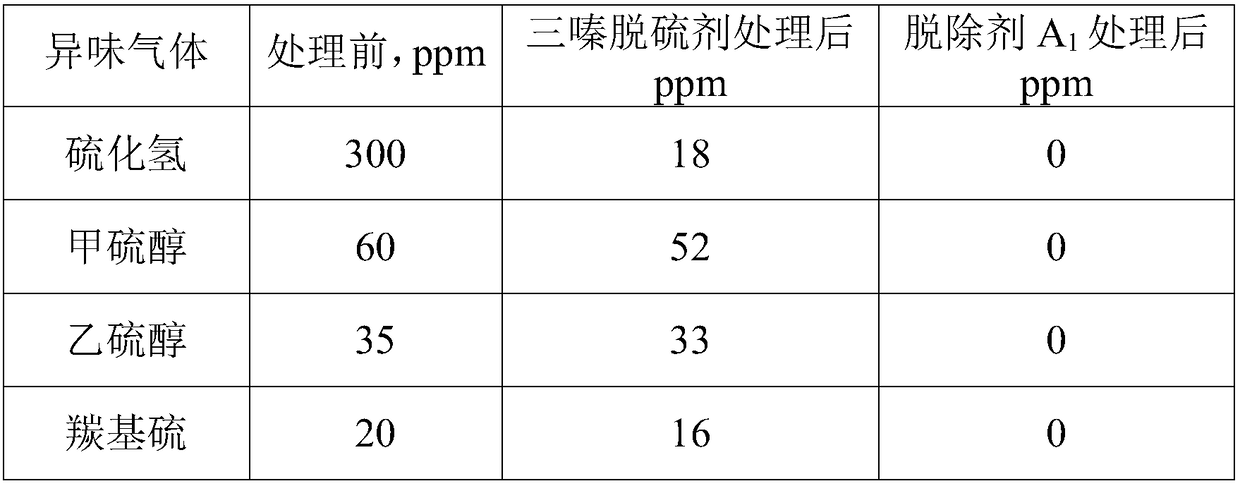

Examples

Embodiment 1

[0026] (1) In the three-necked flask, successively add reaction medium water, 1,3,5-trihydroxyethylhexahydro-s-triazine, and ammonia-hydroxyl complexing agent, and then fix the three-necked flask on an electric heating mantle with a magnetic stirrer superior;

[0027] (2) Put the magnetic rotor into the three-necked bottle, and then install the temperature controller and the separating funnel in the three-necked bottle;

[0028] (3) Turn on the magnetic stirring, the stirring rate is 60rpm, heat the substance in the there-necked flask through the electric heating mantle, and the temperature is controlled by the thermostat at 30°C;

[0029] (4) Add peroxide hydrogen peroxide into the separatory funnel at a rate of 5 drops / min, and react for 0.5h after the addition is completed to obtain the removal agent A 1 .

[0030] The 1,3,5-trihydroxyethylhexahydro-s-triazine, hydrogen peroxide, ammonia hydroxyl complexing agent and water are added in a molar ratio of 1:1:0.01:8.

[003...

Embodiment 2

[0038] (1) In the there-necked bottle, successively add reaction medium water, triazine substance 1,3,5-trihydroxyethylhexahydro-s-triazine, metal complexing agent mercapto complexing agent, then fix the there-necked bottle on the belt On a heating mantle with a magnetic stirrer;

[0039] (2) Put the magnetic rotor into the three-necked bottle, and then install the temperature controller and the separating funnel in the three-necked bottle;

[0040] (3) Turn on the magnetic stirring, the stirring rate is 80rpm, heat the substance in the there-necked flask through the electric heating mantle, and the temperature is controlled by the thermostat at 40°C;

[0041] (4) Add peroxide peracetic acid in the separatory funnel, the addition rate is 6 drops / min, and react for 0.6h after the addition is completed to obtain the removal agent A 2 .

[0042] The 1,3,5-trihydroxyethylhexahydro-s-triazine, peracetic acid, mercapto complexing agent and water are added in a molar ratio of 1:1.5...

Embodiment 3

[0050] (1) In the there-necked flask, successively add reaction medium low-molecular-weight alcohol, triazine substance 1,3,5-trihydroxyethylhexahydro-s-triazine, metal complexing agent ammonia hydroxyl complexing agent, and then the three-necked flask fixed on a heating mantle with a magnetic stirrer;

[0051] (2) Put the magnetic rotor into the three-necked bottle, and then install the temperature controller and the separating funnel in the three-necked bottle;

[0052] (3) Turn on the magnetic stirring, the stirring rate is 100rpm, heat the substance in the there-necked flask through the electric heating mantle, and the temperature is controlled by the temperature controller at 55°C;

[0053] (4) Add peroxide carbamide peroxide in the separatory funnel, the addition speed is 7 drops / min, after the completion of the drop, react for 0.7h to obtain the removal agent A3 .

[0054] The 1,3,5-trihydroxyethylhexahydro-s-triazine, carbamide peroxide, ammonia hydroxyl complexing ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com