A mixed gas foam fracturing fluid system and its preparation

A technology of foam fracturing fluid and mixed gas, which is applied in the direction of drilling composition, chemical instruments and methods, etc., which can solve the problems of increasing the difficulty of fracturing construction, large formation damage, and difficult flowback, etc., to increase reservoir productivity , Improve fracturing effect, and strong flowback performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

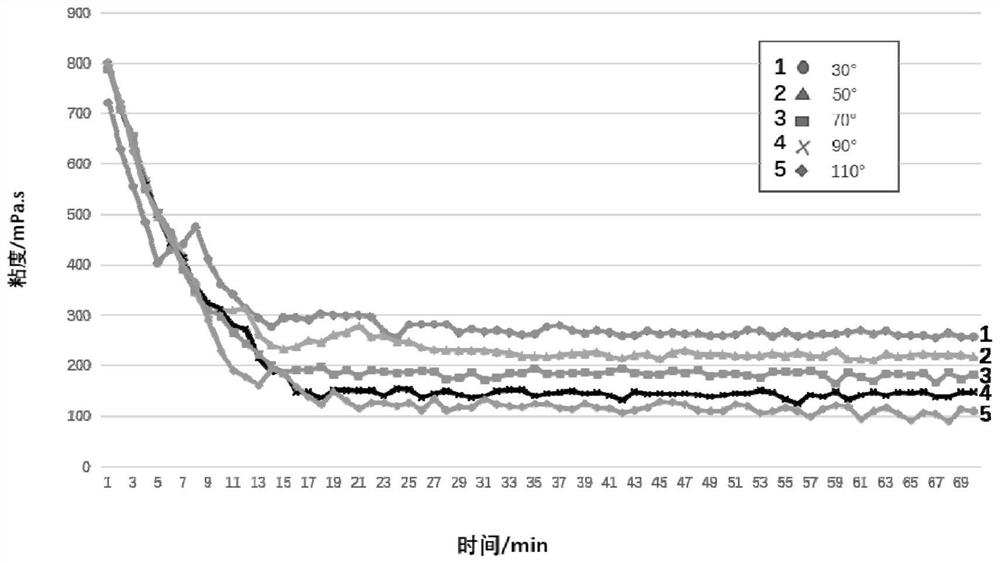

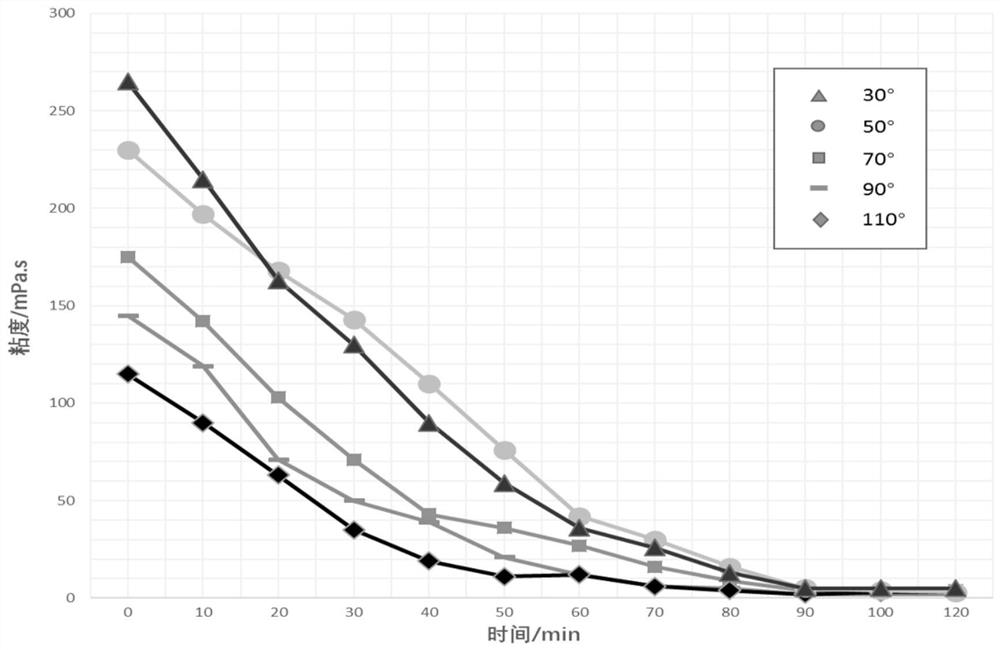

[0037] A mixed gas foam fracturing fluid system, the fracturing fluid system includes a gas phase and a liquid phase, the gas phase is nitrogen, and the liquid phase is mainly composed of 1% foaming agent (cationic Gemini quaternary ammonium salt dioleyl dimethyl ammonium chloride), 0.5% thickener (NH 4 Cl), 1% foam stabilizer (silica nanoparticles with a particle size of 30-80), 50% liquid carbon dioxide and simulated formation water (91.5% active water + 2.0% KCl + 5.5% NaCl + 0.45% MgCl 2 +0.55%CaCl 2 ) composition, the gas-liquid volume ratio is 3:1.

[0038] (1) According to 91.5% active water + 2.0% KCl + 5.5% NaCl + 0.45% MgCl 2 +0.55%CaCl 2 The mass percentage of is prepared as simulated formation water;

[0039] (2) Add 0.5% thickener (NH 4 C1) Add the simulated formation water prepared in step (1), add it into the mixer, and fully stir it for 2 minutes at a speed of 8000r / min to obtain the mixture, which is the base liquid;

[0040] (3) Add 1% foaming agent (Ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com