Methionine oligopeptide and preparation method and application thereof

A technology of methionine and oligopeptides, applied in the field of methionine oligopeptides, can solve the problems of many reagents, cumbersome reactions, and low yields, and achieve the effects of easy operation, simple preparation process, and high yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

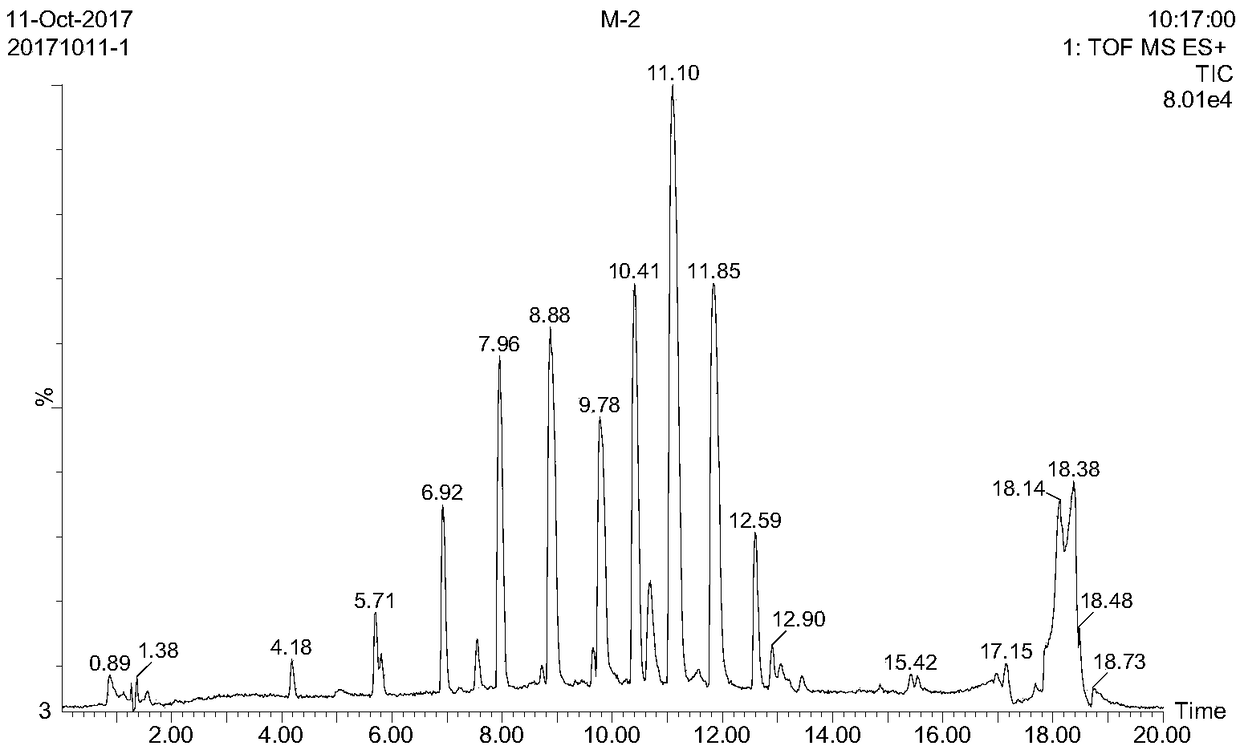

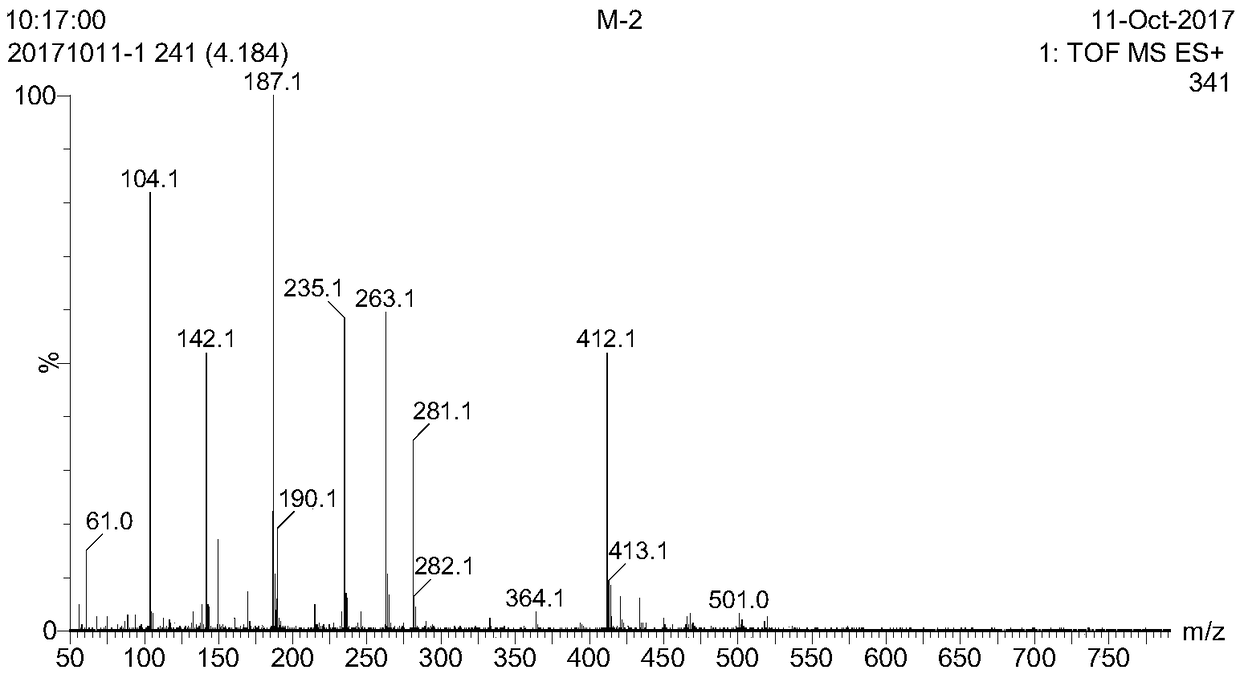

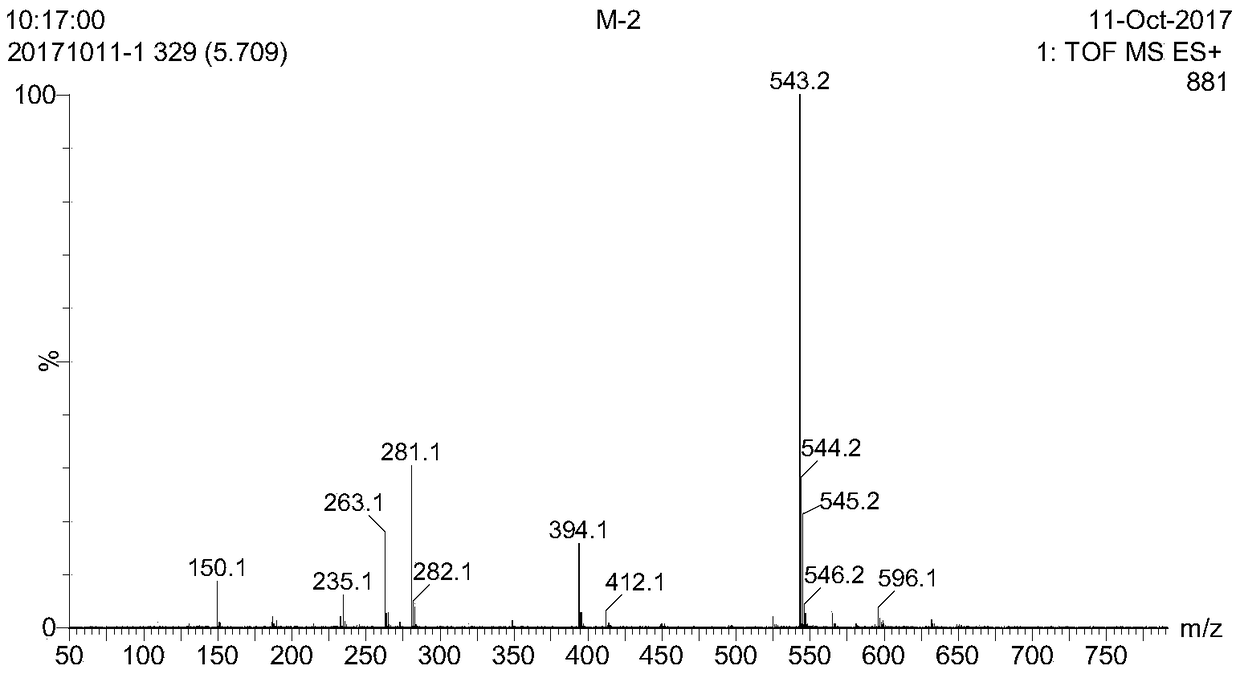

Image

Examples

Embodiment 1

[0061] This embodiment is a preparation method of methionine oligopeptide, which preparation method comprises the following steps:

[0062] (a) dissolving papain in 1.2M potassium phosphate buffer solution with pH7.2, centrifuging at 10000r / min for 6min at 23°C to obtain a papain solution with a concentration of 28mg / ml;

[0063] (b) Dissolve L-Met-OEt.HCl in 1.2M potassium phosphate buffer at pH 7.2, and bathe in water at 45°C for 0.5-1.5min to obtain L-Met-OEt.HCl with a concentration of 0.24-0.26M solution;

[0064] (c) Mix the protease solution and the L-Met-OEt.HCl solution at a volume ratio of 1:1.2, and react at 52°C for 10 hours, and then heat the reaction solution to 90°C for 6 minutes;

[0065] (d) cooling the inactivated mixed solution, centrifuging to collect the precipitate, washing the precipitate with water, and freeze-drying to obtain the methionine oligopeptide.

[0066] Weigh the methionine oligopeptide prepared by the above method, and calculate the yield ...

Embodiment 2

[0068] This embodiment is a preparation method of methionine oligopeptide, which preparation method comprises the following steps:

[0069] (a) dissolving papain in 0.8M potassium phosphate buffer solution with pH7.0, centrifuging at 15000r / min for 4min at 27°C to obtain a papain solution with a concentration of 22mg / ml;

[0070] (b) Dissolve L-Met-OEt.HCl in 0.8M potassium phosphate buffer solution with pH 7.0, and bathe in water at 55°C for 0.5-1.5min to obtain a 0.26M L-Met-OEt.HCl solution;

[0071] (c) Mix the protease solution and the L-Met-OEt.HCl solution at a volume ratio of 1:0.8, and react at 48°C for 10 hours, and then heat the reaction solution to 92°C for 4 minutes;

[0072] (d) cooling the inactivated mixed solution, centrifuging to collect the precipitate, washing the precipitate with water, and freeze-drying to obtain the methionine oligopeptide.

[0073] According to the yield calculation method in Example 1, the yield of methionine oligopeptide prepared by ...

Embodiment 3

[0075] This embodiment is a preparation method of methionine oligopeptide, which preparation method comprises the following steps:

[0076] (a) dissolving papain in 1M potassium phosphate buffer solution with pH 7.0, centrifuging at 12000r / min for 5min at 25°C to obtain a papain solution with a concentration of 25mg / ml;

[0077] (b) Dissolve L-Met-OEt.HCl in 1M potassium phosphate buffer solution with pH 7.0, and bathe in water at 50°C for 1 min to obtain a 0.25M L-Met-OEt.HCl solution;

[0078] (c) Mix the protease solution and the L-Met-OEt.HCl solution at a volume ratio of 1:1, and react at 50°C for 12 hours, and then heat the reaction solution to 90°C for 5 minutes;

[0079] (d) cooling the inactivated mixed solution, centrifuging to collect the precipitate, washing the precipitate with water, and freeze-drying to obtain the methionine oligopeptide.

[0080] According to the yield calculation method in Example 1, the yield of methionine oligopeptide prepared by the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com