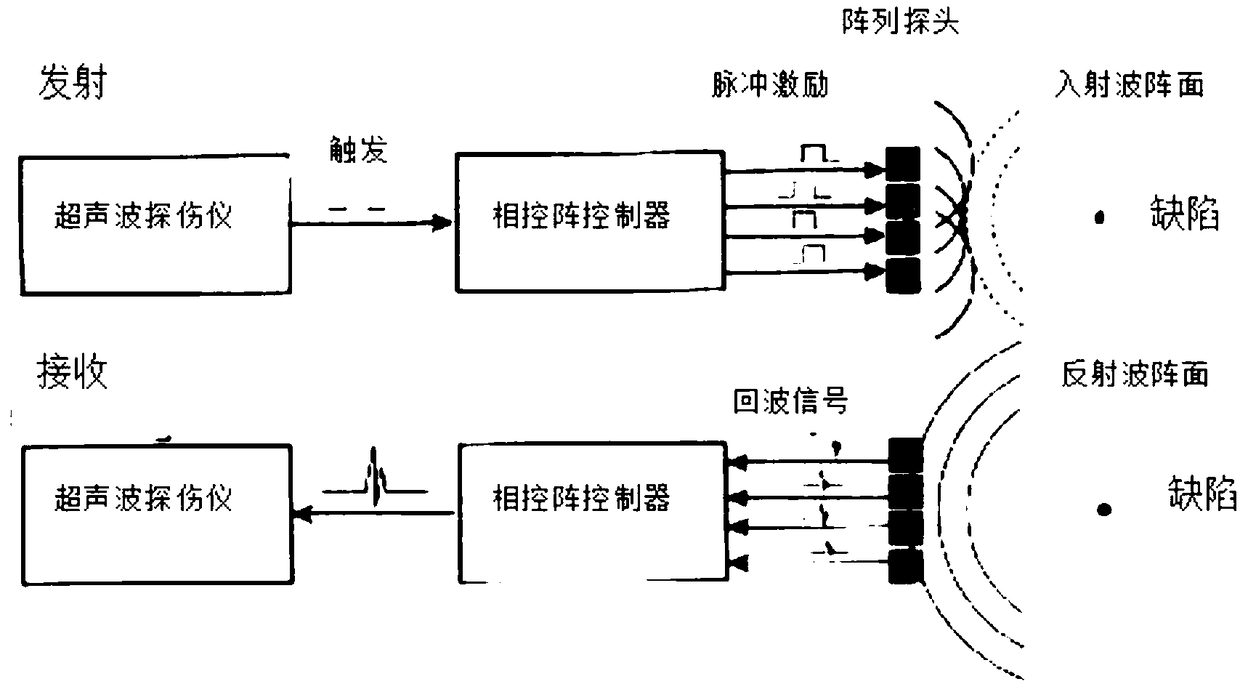

Intermediate and large diameter thin-wall pipe nondestructive detection method based on phased array ultrasonic flaw detector

An ultrasonic flaw detection and non-destructive testing technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc. problem, to achieve intuitive detection effect, convenient defect analysis, and the effect of reducing the near-field area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

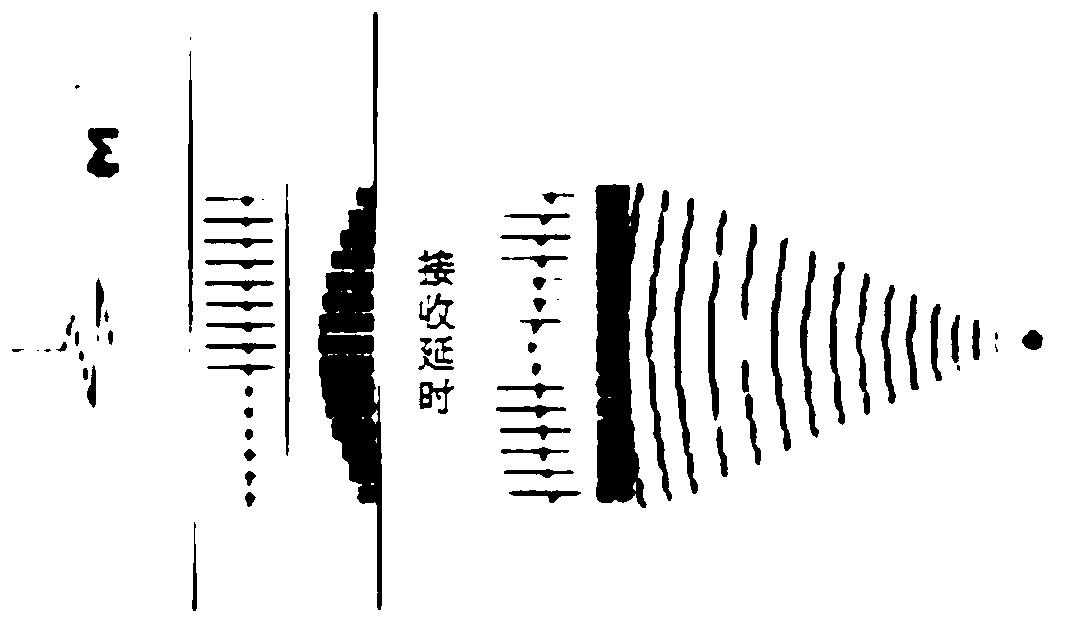

Method used

Image

Examples

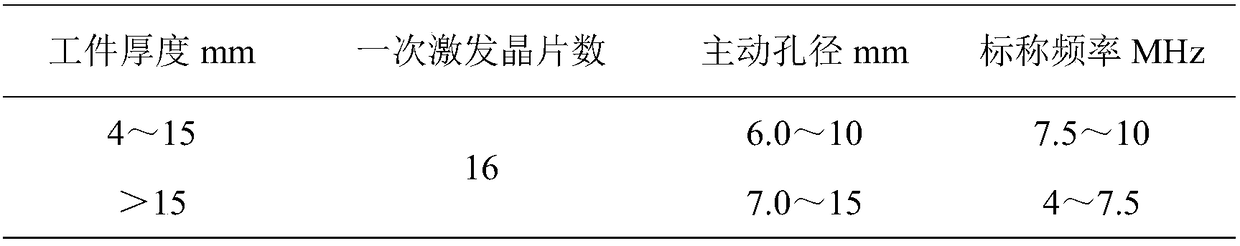

Embodiment 1

[0078] 89mm ≤ outer diameter ≤ 159mm, 4mm ≤ wall thickness ≤ 20mm pipe diameter, the probe model used in the actual work is "Sontron NDT 7.5S16-0.5×10" (frequency is 7.5MHz, the distance between the centerlines of two adjacent chips is p= 0.5mm, chip width or array element width is e=0.4mm, gap between two adjacent chips is g=0.1mm), the wedge chooses the probe wedge that matches the curvature of the pipe to be inspected (customized or flat wedge grinding) . Select the special DL-1(5) comparison test block specified in DL / T820 for ultrasonic inspection of small-diameter pipe welded joints to measure probe parameters, system combination performance, calibrate time base linearity and make DAC curves. The artificially simulated defect samples with similar specifications to the inspected workpiece are selected for the determination of scanning sensitivity and the verification of detection process. The number of wafers to be excited at one time is 16 wafers, and the maximum angle ...

Embodiment 2

[0081] For pipes with outer diameter >159mm, 4mm≤wall thickness≤20mm, the selected probe model is "Sontron NDT 4L16-0.5×9" (frequency is 4MHz, distance between the centerlines of two adjacent chips is p=0.5mm, chip width or array element width e=0.4mm, the gap between two adjacent wafers is g=0.1mm), and the wedge is a flat wedge corresponding to the probe. The selected comparison test block is upgraded on the basis of the DL-1 type comparison test block for ultrasonic inspection of DL / T820 small-diameter pipe welded joints. 9" is in good contact with the sample. Measure probe parameters, system combination performance, calibrate time base linearity and make DAC curve according to customized test block. The artificially simulated defect samples with similar specifications to the inspected workpiece are selected for the determination of scanning sensitivity and the verification of detection process. One excitation chip is 16 chips, and the maximum angle range of the selected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com