A preparation method of a low-cost P-type all-back-electrode crystalline silicon solar cell

A crystalline silicon solar cell and full-back electrode technology, applied in the field of solar cells, can solve the problems of relatively high minority carrier life requirements, different doping types, complex process flow, etc. effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

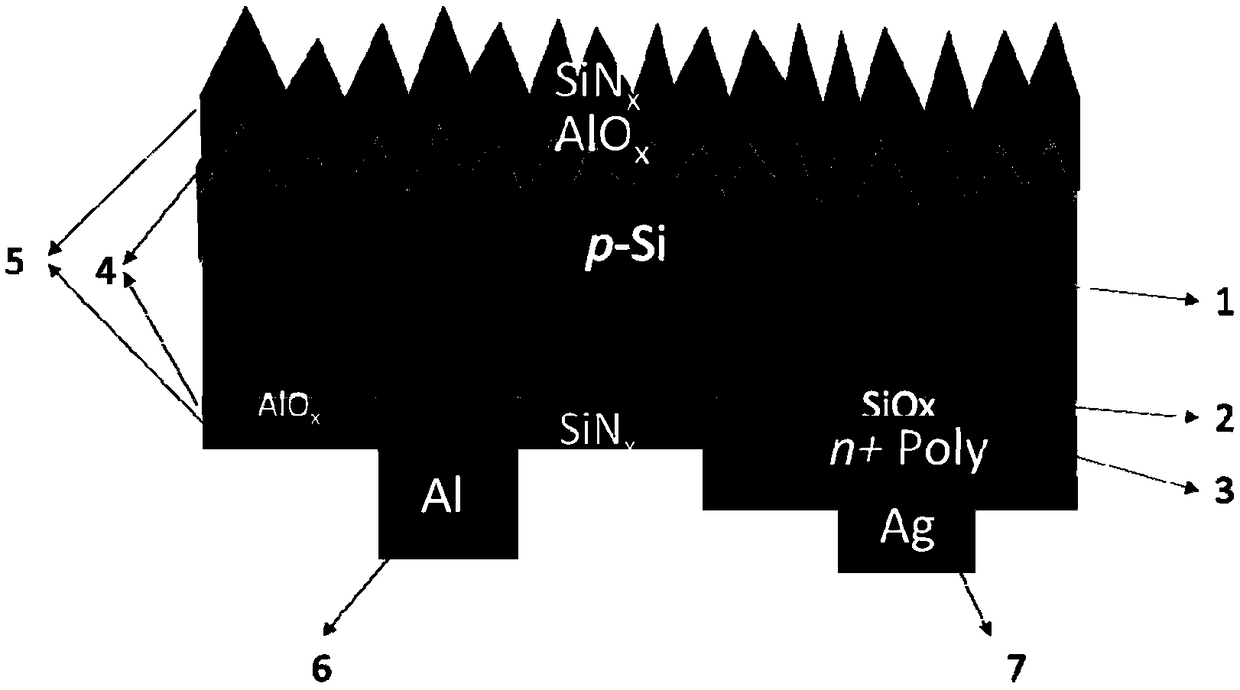

[0032] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0033] Such as figure 1 As shown, a low-cost P-type all-back electrode crystalline silicon solar cell, the specific structure is as follows:

[0034] (1) The battery uses a P-type monocrystalline silicon wafer as the substrate 1, such as figure 1 As shown in the middle area 1, the resistivity of the silicon wafer is 1-5ohm·cm, the front of the silicon wafer is pyramid-shaped suede, and the back is a polished plane;

[0035] (2) The emitter junction area on the back of the battery has a tunnel oxide layer 2, such as figure 1 As shown in the middle area 2, the thickness of the oxide layer is 1-2nm, and a tunneling contact can be formed;

[0036] (3) A heavil...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap