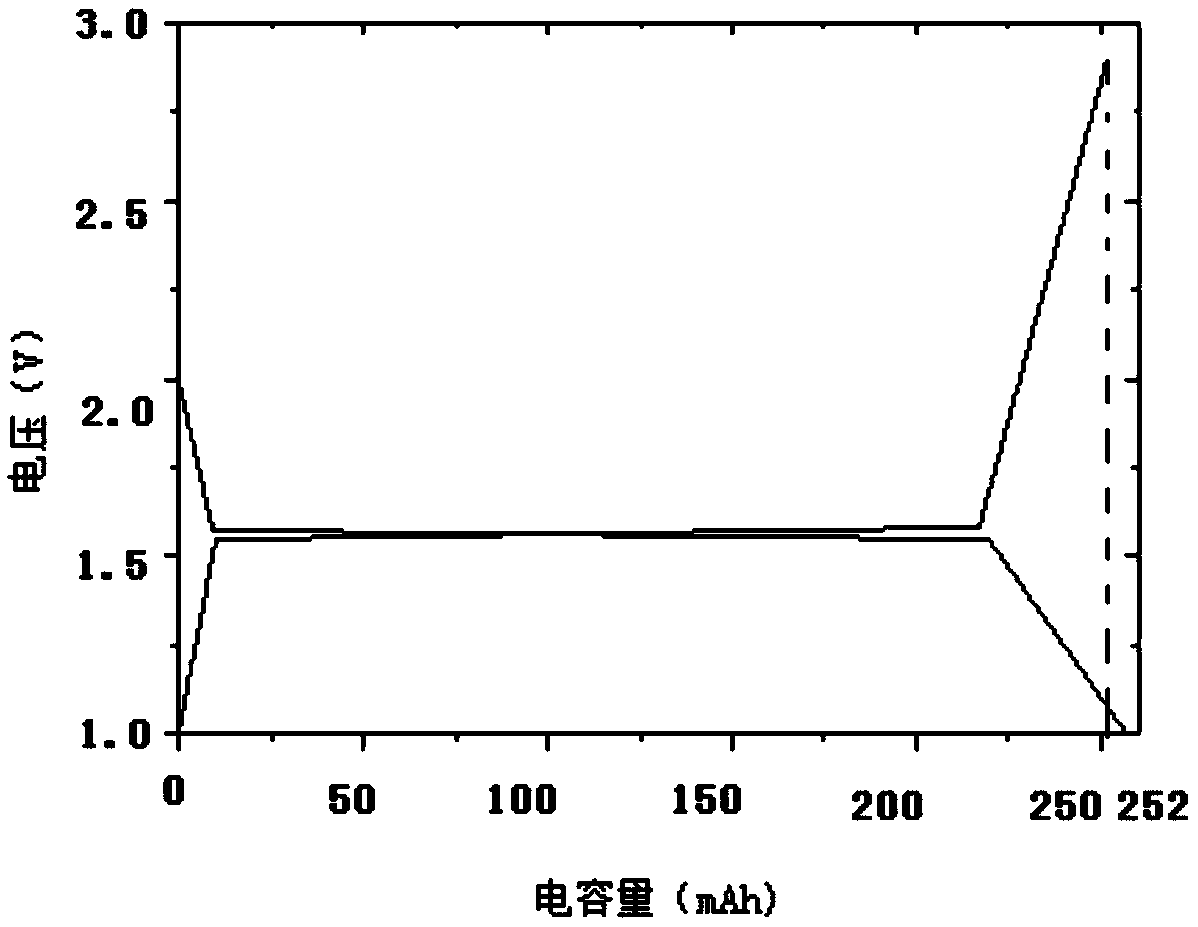

A method for improving that capacity of 1.55 V carbon coated lithium titanate battery

A carbon-coated lithium titanate and battery capacity technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of loss of battery performance, unsafe silicon materials, and reduced battery cycle times, and break the bottleneck of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] A method for increasing the capacity of a 1.55V carbon-coated lithium titanate battery, characterized in that the preparation method is:

[0022] Step 1: Prepare raw materials

[0023] Weigh the four raw materials of lithium hydroxide, titanium oxide, terbium oxide and glucose, the molar ratio of lithium, titanium and terbium is required to meet 1.323:1.666:0.01, and the weight of glucose is 20% of the total weight of the other three raw materials

[0024] In the second step, after mixing the lithium hydroxide, titanium oxide, terbium oxide and glucose with a grinding particle size of less than 50nm in the above ratio, place it in a high-temperature furnace under an argon atmosphere, and raise the temperature to 700 at a heating rate of 12-18°C / min. -900°C, and then kept at this temperature for 5-10 hours, aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com