A multistage layer-coated ternary cathode material for A lithium ion batterY, a preparation method thereof and a lithium ion battery

A technology for lithium ion batteries and positive electrode materials, which is applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems of poor uniformity of active material coating, reduced material cycle stability, and limited effect, so as to improve thermal efficiency. Stability and cycle life, simple preparation method, effect of inhibiting reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

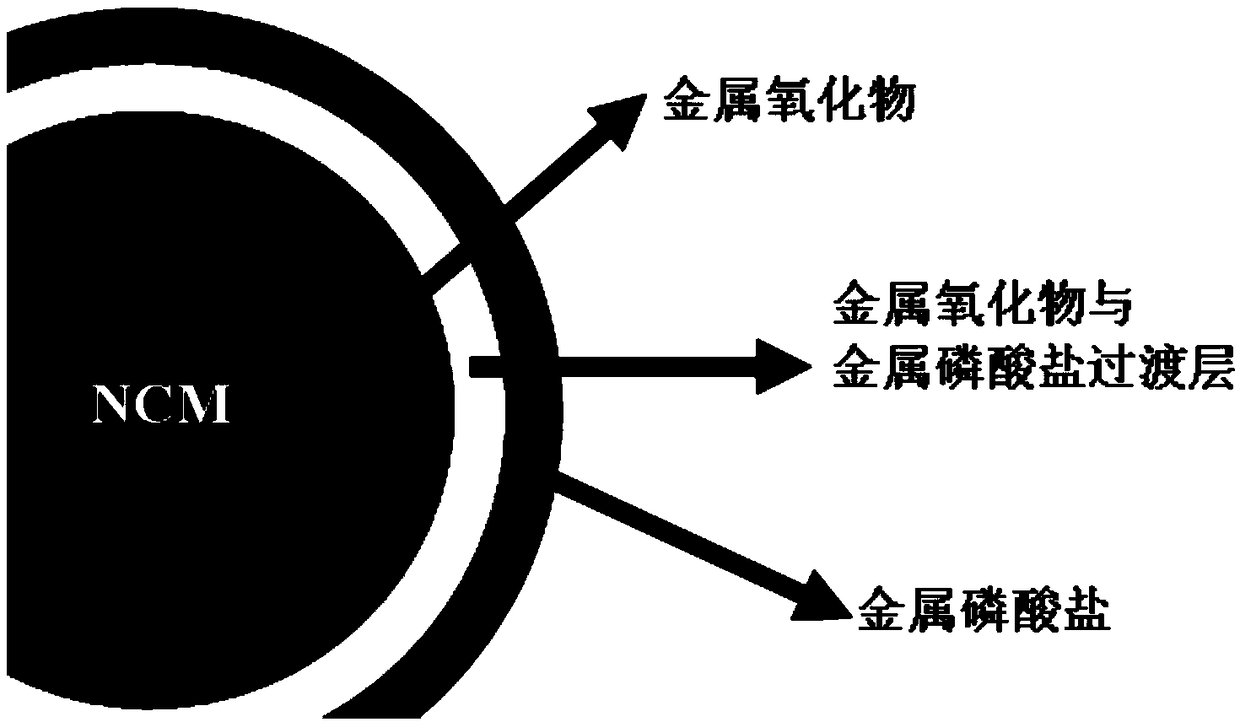

[0052] The present invention also provides a method for preparing the above-mentioned ternary positive electrode material, comprising the following steps:

[0053] A) preparing an aqueous solution of a soluble first metal-coated element salt to obtain a first coating solution;

[0054] preparing a salt solution of a soluble second metal coating element to obtain a second coating solution;

[0055] preparing an aqueous solution of a soluble phosphoric acid compound to obtain a third coating solution;

[0056] B) dispersing the ternary cathode material substrate in deionized water to obtain a suspension;

[0057] Under alkaline conditions, dropwise adding the first coating solution to the suspension for reaction to obtain a reaction product;

[0058] Drying the reaction product and performing heat treatment to obtain an intermediate reaction product;

[0059] C) dispersing the intermediate reaction product in deionized water to obtain a suspension;

[0060] Under alkaline co...

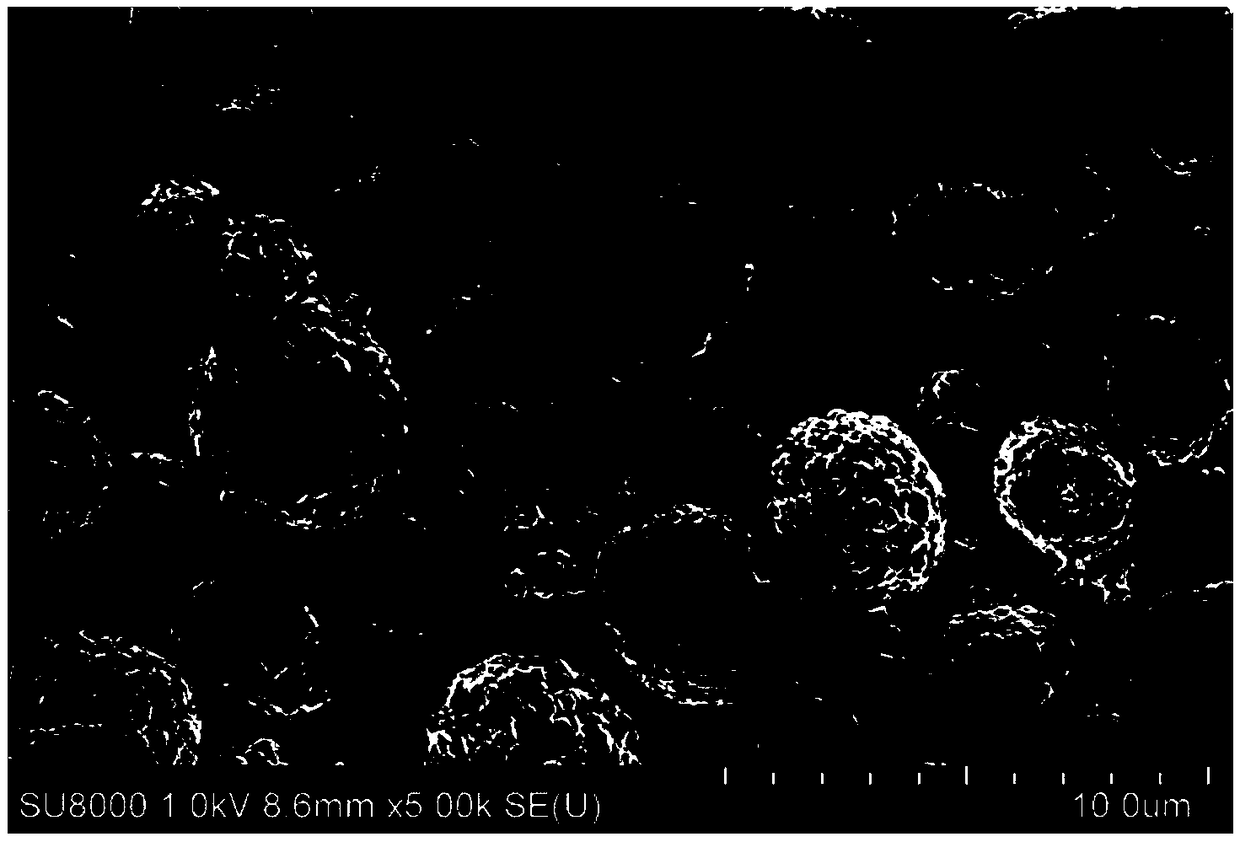

Embodiment 1

[0098] 1.1 Dissolve 20g of aluminum nitrate nonahydrate in 80ml of deionized water to obtain coating solution 1;

[0099] 1.2 Add 1Kg Ni 0.6 co 0.2 mn 0.2 o 2 The ternary positive electrode material is dispersed in 1000ml of deionized water to form a suspension 1, 1 drop of the coating solution obtained in step (1) is added to the suspension 1, and 2mol / L lithium hydroxide solution is added to control the pH of the reaction system=7.5, React for 2 hours, then suction filter, wash, dry, and heat-treat at 350°C for 6 hours at a heating rate of 3°C / min to obtain an intermediate reactant;

[0100] 1.3 Dissolve 5g of aluminum nitrate nonahydrate in 80ml of deionized water to obtain coating solution 2; dissolve 1.7g of diammonium hydrogen phosphate in 80ml of deionized water to obtain coating solution 3;

[0101] 1.4 Disperse the intermediate reactants obtained in step 2 in 1000ml deionized water to form suspension 2, add coating solution 2 and coating solution 3 obtained in ste...

Embodiment 2

[0105] 2.1 Dissolve 18g of magnesium sulfate heptahydrate in 80ml of deionized water to obtain coating solution 1;

[0106] 2.2 Put 1Kg Ni 0.5 co 0.2 mn 0.3 o 2 The ternary positive electrode material is dispersed in 1000ml of deionized water to form a suspension 1, 1 drop of the coating solution obtained in step (1) is added to the suspension 1, and 2mol / L lithium hydroxide solution is added to control the pH of the reaction system=10.0, React for 3 hours, then suction filter, wash and dry, and heat-treat at 400°C for 6 hours at a heating rate of 4°C / min to obtain the intermediate reactant;

[0107] 2.3 Dissolve 7.5g of lanthanum nitrate hexahydrate in 80ml of deionized water to obtain coating solution 2; dissolve 3.52g of ammonium phosphate in 80ml of deionized water to obtain coating solution 3;

[0108] 2.4 Disperse the intermediate reactants obtained in step 2 in 1000ml deionized water to form suspension 2, add coating solution 2 and coating solution 3 obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com