Non-Newtonian fluid Na-K alloy electrode and preparation method and application thereof

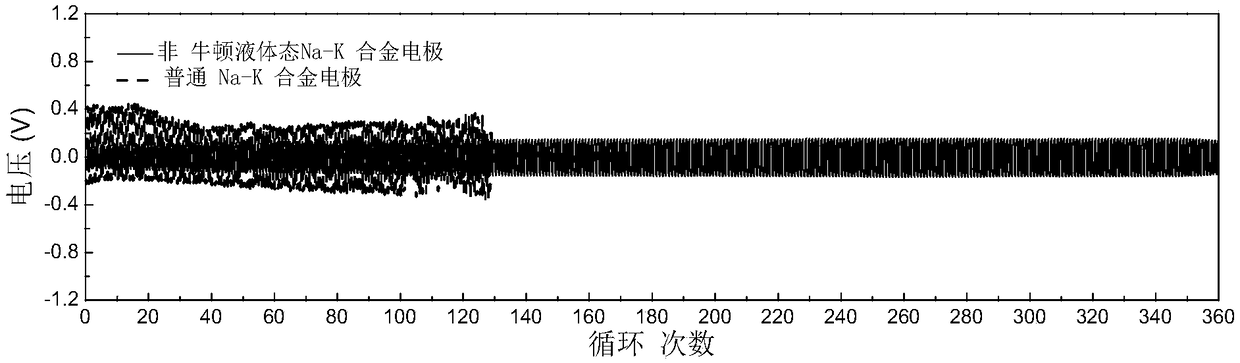

A non-Newtonian fluid and alloy electrode technology, which is applied in electrode manufacturing, battery electrodes, electrode collector coatings, etc., can solve problems such as changing the properties of liquid Na-K alloy fluids, and achieve improved energy density and cycle stability. Effect of High Coulombic Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Under the protection of inert gas argon, K metal and Na metal need to be cut to remove surface oxides before use, 0.1g K metal and 0.028g Na metal are stacked in a glove box, and after a period of reaction, a liquid Na-K alloy is formed. Mix 1 g of glucose with 500 mL of an aqueous solution containing 1% by mass of surfactant (sodium alkylbenzene sulfonate), then pour it into a hydrothermal tank, heat it at 180° C. for 12 hours, and wash to obtain carbon nanospheres. Mix 0.128g of liquid Na-K alloy with 0.5g of nano-carbon spheres, and continue to stir until a viscous mixture is formed to form a non-Newtonian fluid Na-K alloy (ie, a non-Newtonian fluid Na-K alloy composite material), and then coat A non-Newtonian fluid state Na-K alloy coating is formed on the surface of the copper sheet to prepare a non-Newtonian fluid state Na-K alloy electrode.

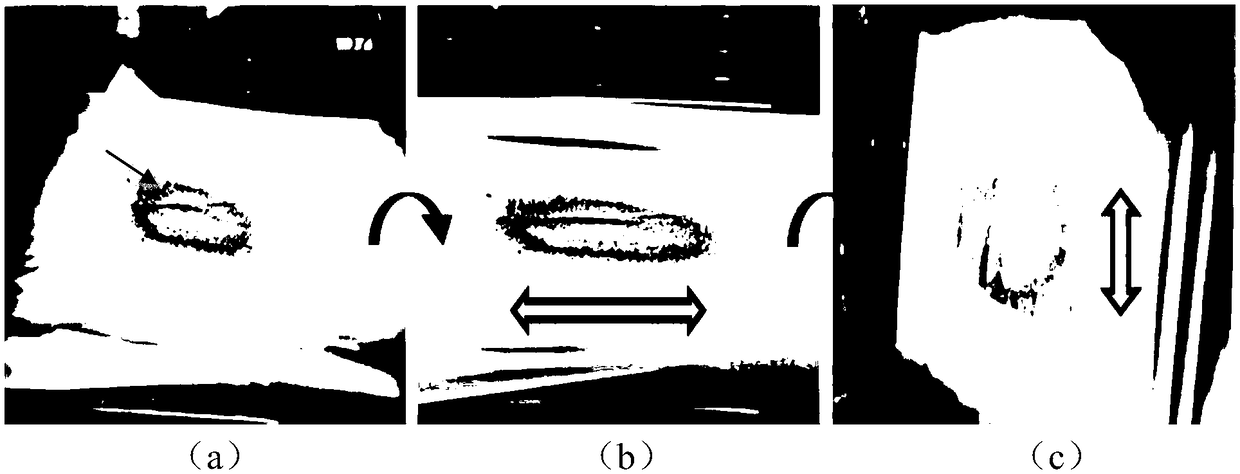

[0038] The non-Newtonian fluid state Na-K alloy prepared in Example 1 is relatively viscous and can be coated. figure 1 A ...

Embodiment 2

[0040] Under the protection of inert gas argon, K metal and Na metal need to be cut to remove surface oxides before use, 0.2g K metal and 0.056g Na metal are stacked in a glove box, and after a period of reaction, a liquid Na-K alloy is formed. Mix 2.5g of copper dichloride dihydrate with 1000mL of an aqueous solution containing 1% by mass of surfactant (sodium alkylbenzene sulfonate), and then pour it into a hydrothermal tank, heat it at 160°C for 11 hours, and wash to obtain Copper oxide nanopowder. Mix 0.256g of liquid Na-K alloy with 0.2g of copper oxide nanopowder, and keep stirring until a viscous mixture is formed, that is, a non-Newtonian fluid Na-K alloy is formed, and then coated on the surface of carbon cloth to obtain a non-Newtonian flow Bulk Na-K alloy electrode.

[0041] The performance of the obtained electrode is similar to Example 1.

Embodiment 3

[0043] Under the protection of inert gas argon, K metal and Na metal need to be cut to remove surface oxides before use, 0.2g K metal and 0.056g Na metal are stacked in a glove box, and after a period of reaction, a liquid Na-K alloy is formed. Mix 1.8g of silicon oxide powder with 1000mL of an aqueous solution containing 1% by mass of surfactant (sodium alkylbenzene sulfonate) evenly, then pour it into a hydrothermal tank, heat it at 180°C for 12 hours, and wash to obtain silicon nanopowder . Mix 0.256g of liquid Na-K alloy with 0.4g of silicon nanopowder, and keep stirring until a viscous mixture is formed, that is, a non-Newtonian fluid state Na-K alloy is formed, and then coated on the surface of a plastic film to obtain a non-Newtonian fluid state Na-K alloy electrode.

[0044] The performance of the obtained electrode is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com