A method for manufacturing an electromagnetic shielding optical window by using electric field driven jet 3D printing

A 3D printing and electromagnetic shielding technology, which is applied in the fields of magnetic/electric field shielding, additive manufacturing, electrical components, etc., can solve the problem of inability to achieve high-viscosity and high-silver-content nano-silver paste printing, limited viscosity of printing materials, and difficulty in large-area manufacturing, etc. problems, to achieve excellent electromagnetic shielding efficiency, super electromagnetic shielding performance, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

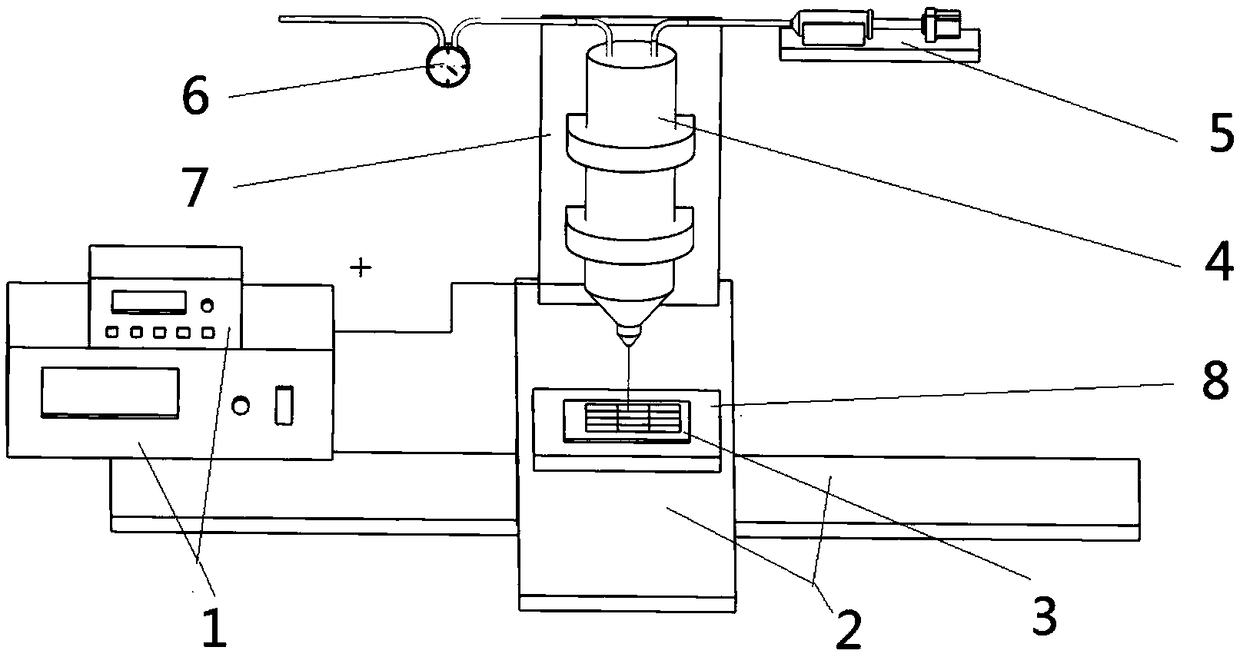

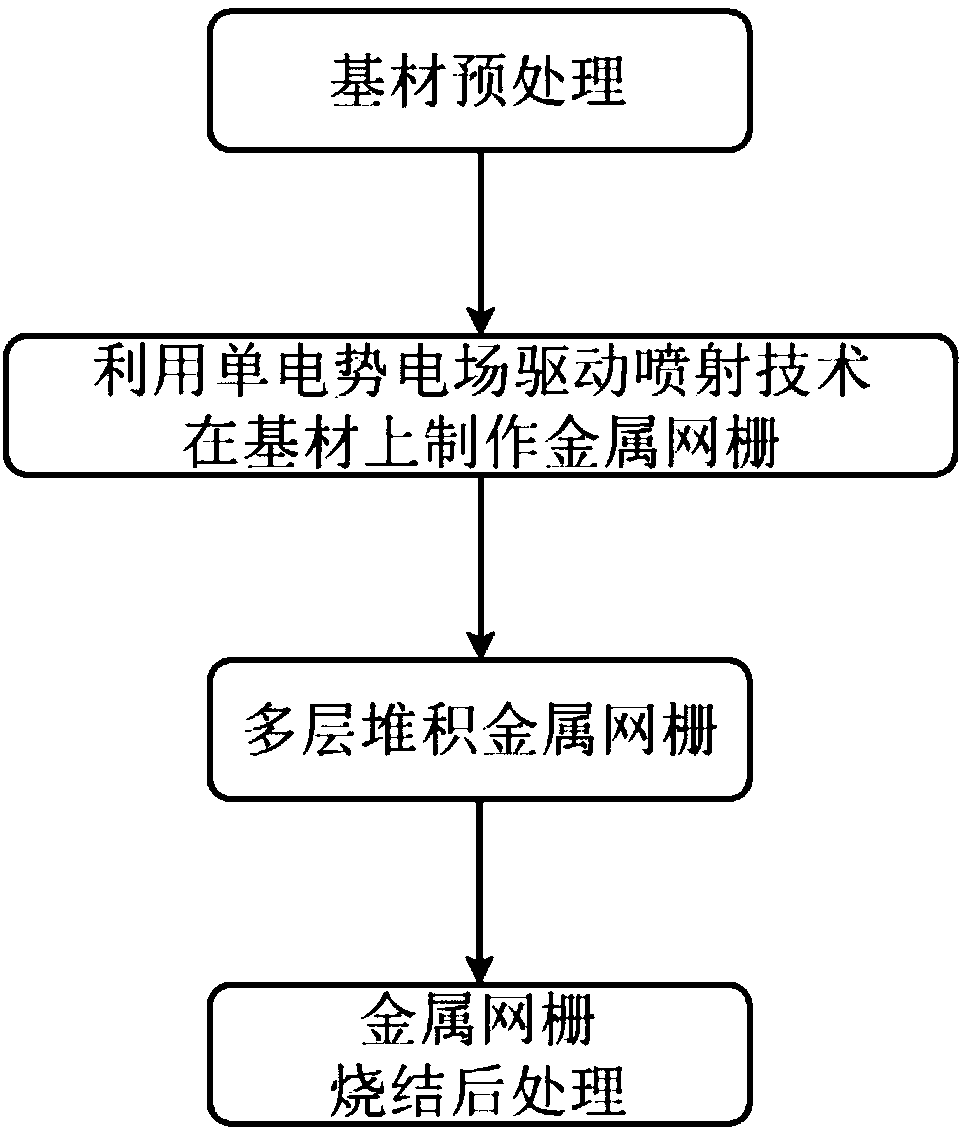

[0060] In this embodiment, the glass of 200x200mm is used as the base material, the particle-free nano-silver paste is used as the printing material (the silver content exceeds 20%), and the glass needle is used as the nozzle, and the production cycle of the 3D printer driven by electric field is 100 microns. A metal grid with a width of 2 microns and an aspect ratio of 2:1, the working principle of the electric field-driven jet deposition 3D printer is as follows figure 1 As shown, the manufacturing process of metal grid electromagnetic shielding optical window is as follows figure 2 As shown, the specific steps include:

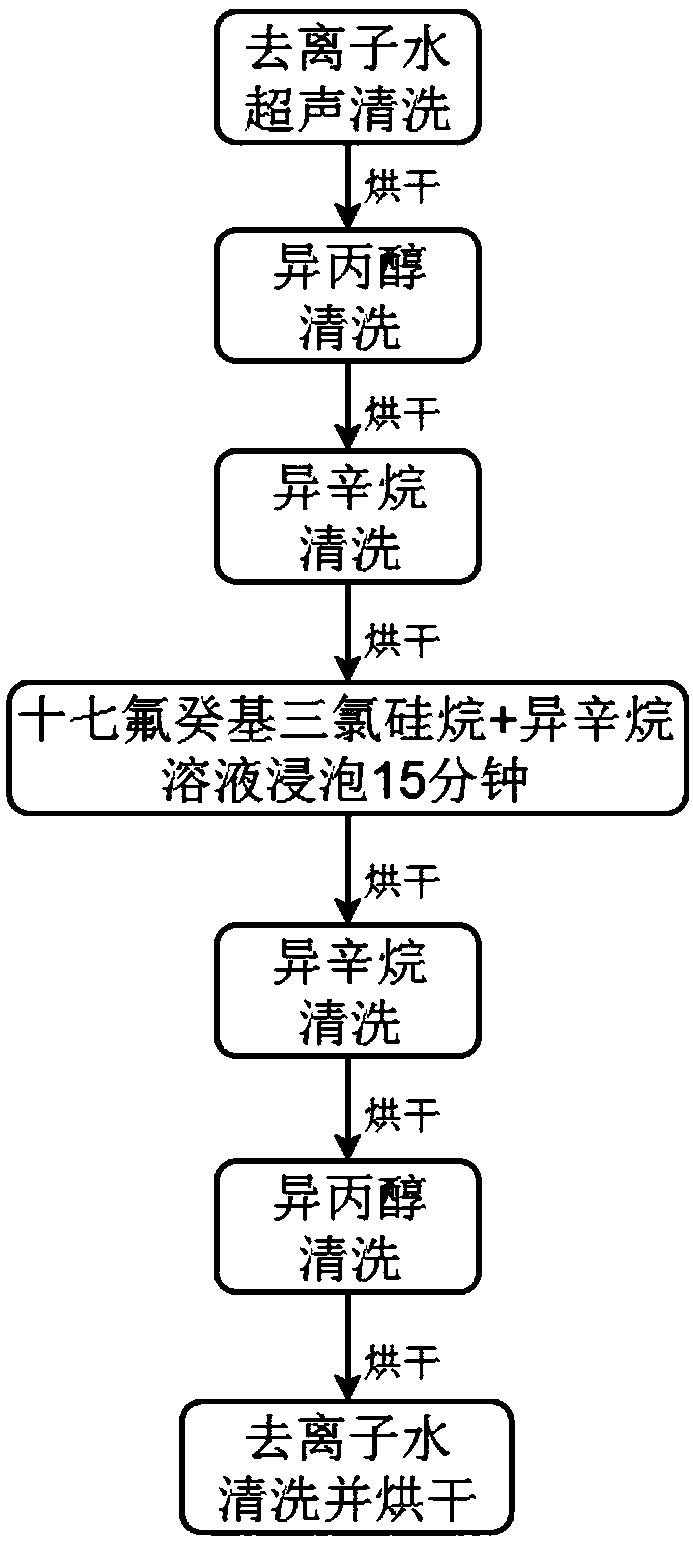

[0061] Step 1: Substrate pretreatment. according to image 3 The process is to pretreat the glass substrate, including: deionized water ultrasonic cleaning, isopropanol cleaning, isooctane cleaning, heptadecafluorodecyltrichlorosilane + isooctane solution soaking for 15 minutes, isooctane cleaning , isopropanol cleaning, deionized water cleaning and dry...

Embodiment 2

[0065] In this example, 300x300mm glass is used as the base material, the glass needle is used as the nozzle, and nano-particle silver paste is used as the printing material. The production cycle of the 3D printer is 150 microns, the line width is 3 microns, and the aspect ratio is 1:1. The metal grid, the specific steps include:

[0066] Step 1: Substrate pretreatment. Pretreatment of the glass substrate, including: deionized water ultrasonic cleaning, isopropanol cleaning, isooctane cleaning, heptadecafluorodecyltrichlorosilane + isooctane solution soaking for 15 minutes, isooctane cleaning, isooctane Rinse with propanol, deionized water and dry.

[0067] Step 2: 3D print the metal grid. Using the electric field-driven spray deposition 3D printing process, the metal grid is printed on the pretreated substrate surface according to the set path. First, print the first layer of metal grid on the substrate, and then use the self-focusing effect of electric field-driven jet 3D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com