Antibacterial promoting healing foam dressing, preparation method thereof and application

A technology of foam and foam stabilizer, which is applied in the field of medicine, can solve problems such as poor stability, inconvenient use, and failure to meet the requirements of use, and achieve the effects of fast wound healing, excellent anti-inflammatory, and inhibition of bacterial growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

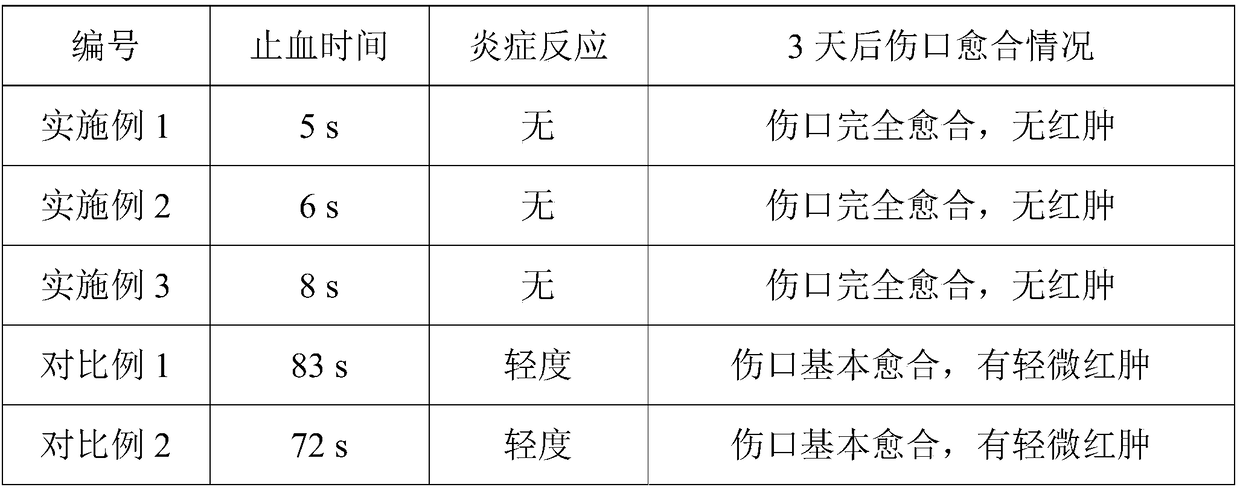

Embodiment 1

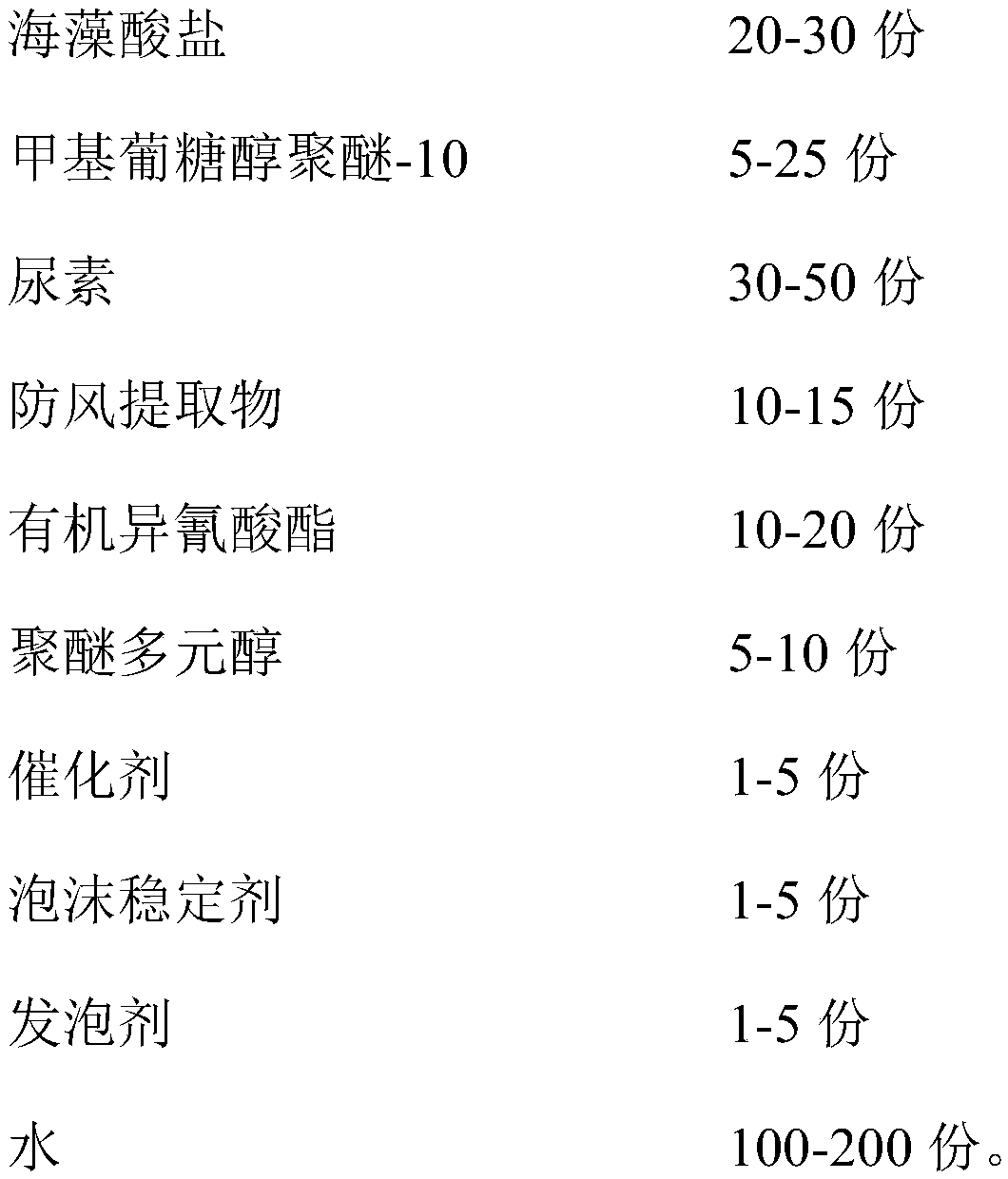

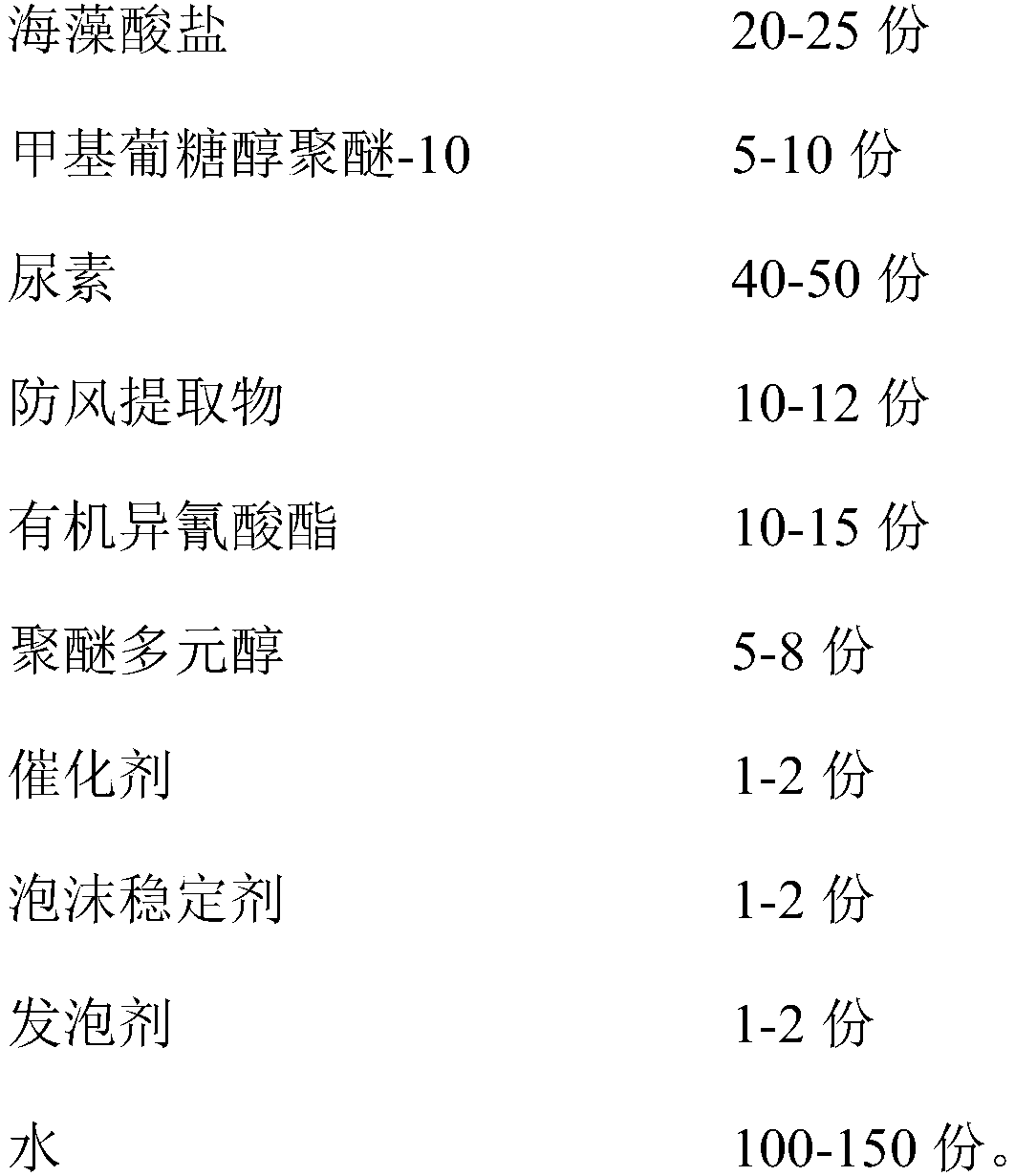

[0057] The foam dressing is prepared from the following raw materials in parts by weight:

[0058] Calcium alginate 15 parts, sodium alginate 10 parts, methyl gluceth-10 10 parts, urea 40 parts, windproof extract 12 parts, toluene diisocyanate 15 parts, polyether propylene glycol 4 parts, polyether glycerine 4 parts of alcohol, 1 part of stannous octoate, 1 part of dibutyltin, 2 parts of silicone foam stabilizer, 1 part of tetrahydrofuran, 1 part of petroleum ether and 150 parts of water.

[0059] Preparation:

[0060] (1) Calcium alginate, sodium alginate, methyl gluceth-10, urea, toluene diisocyanate, polyether propylene glycol, polyether glycerin, stannous octoate, dibutyltin, silicone Mix foam stabilizer, tetrahydrofuran, petroleum ether and water, and stir for 5 minutes at 25°C;

[0061] (2) Add the windproof extract according to the formula, stir for 3 minutes, place in a foaming mold, keep warm at 60° C. for 15 minutes, remove the mold and cut to obtain the foam dress...

Embodiment 2

[0063] The foam dressing is prepared from the following raw materials in parts by weight:

[0064] Calcium alginate 20 parts, methyl gluceth-10 25 parts, urea 30 parts, parsnip extract 15 parts, toluene diisocyanate 10 parts, polyether propylene glycol 10 parts, triethanolamine 1 part, silicone foam stabilizer 1 part, 1 part tetrahydrofuran, 1 part petroleum ether, 1 part trichlorofluoromethane, 2 parts dichlorotetrafluoroethane and 100 parts water.

[0065] Preparation:

[0066] (1) Calcium alginate, methyl gluceth-10, urea, toluene diisocyanate, polyether propylene glycol, triethanolamine, silicone foam stabilizer, tetrahydrofuran, petroleum ether, trichlorofluoromethane, Dichlorotetrafluoroethane and water were mixed and stirred at 20°C for 10 minutes;

[0067] (2) Add the windproof extract according to the formula, stir for 1 minute, place in a foaming mold, keep warm at 65° C. for 10 minutes, remove the mold and cut to obtain the foam dressing.

Embodiment 3

[0069] The foam dressing is prepared from the following raw materials in parts by weight:

[0070] 30 parts of sodium alginate, 5 parts of methyl gluceth-10, 50 parts of urea, 10 parts of windproof extract, 20 parts of toluene diisocyanate, 5 parts of polyether glycerol, 1 part of stannous octoate, dibutyltin 1 part, 1 part of triethanolamine, 1 part of triethylenediamine, 1 part of triethylamine, 5 parts of silicone foam stabilizer, 1 part of tetrahydrofuran and 200 parts of water.

[0071] Preparation:

[0072] (1) Sodium alginate, methyl gluceth-10, urea, toluene diisocyanate, polyether glycerol, stannous octoate, dibutyltin, triethanolamine, triethylenediamine, triethyl Mix amine, silicone foam stabilizer, tetrahydrofuran and water, and stir at 30°C for 1 min;

[0073] (2) Add the windproof extract according to the formula, stir for 5 minutes, place in a foaming mold, keep warm at 55° C. for 20 minutes, remove the mold and cut to obtain the foam dressing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com