Composite geopolymer lightweight moisture-regulating material and preparation method thereof

A humidity-adjusting material and geopolymer technology, applied in cement production, etc., can solve the problems of limited moisture absorption and desorption capacity, slow moisture absorption and desorption speed, etc., and achieve high-efficiency moisture absorption and desorption performance, simple process, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

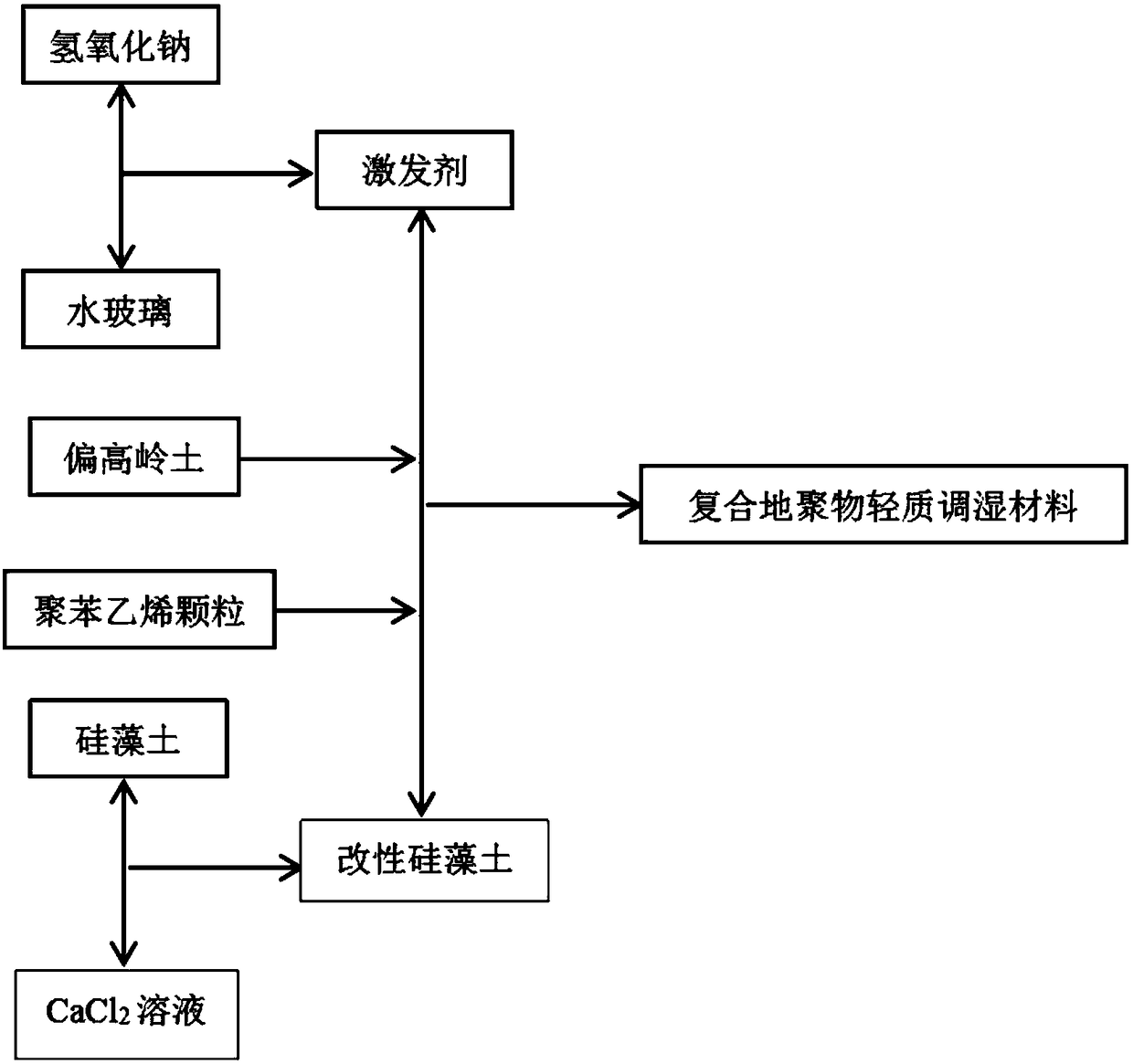

Method used

Image

Examples

Embodiment 1

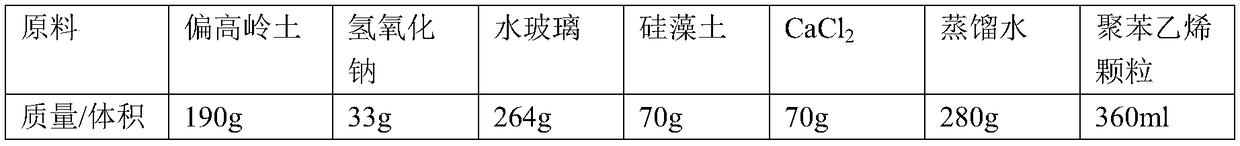

[0035] A composite geopolymer lightweight humidity-conditioning material in this embodiment, the humidity-conditioning material is prepared from the raw material components in Table 1 below, wherein: the average particle size of the metakaolin is 10 μm; the modified Diatomaceous earth is made of calcium chloride (CaCl 2 ) is prepared by modifying diatomite;

[0036] The modulus of the activator is 1.2 to 1.6;

[0037] The modulus of the water glass is 3.1-3.4, the content of silicon dioxide is ≥ 26%, and the content of sodium oxide is ≥ 8.2%. The specification of the purity of the sodium hydroxide is chemically pure, and the purity is ≥ 99%.

[0038] Each raw material component and content used in the preparation of the humidity-conditioning material in Table 1 Example 1

[0039]

[0040] The composite geopolymer lightweight humidity-controlling material described above in this embodiment is prepared by the following method, including the following steps:

[0041] 1) Dis...

Embodiment 2

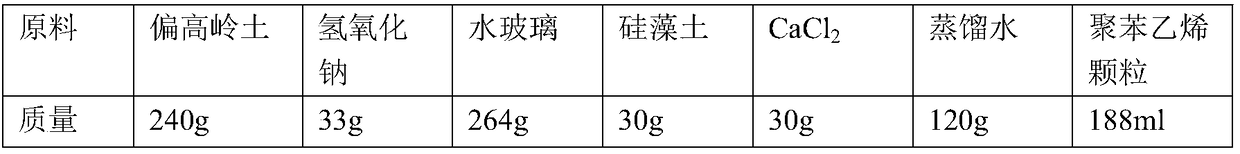

[0053] A composite geopolymer lightweight humidity-conditioning material in this embodiment, the humidity-conditioning material is prepared from the raw material components in Table 2 below, wherein: the average particle size of the metakaolin is 10 μm; the modified Diatomaceous earth is made of calcium chloride (CaCl 2 ) is prepared by modifying diatomite;

[0054] The modulus of the activator is 1.2 to 1.6;

[0055] The modulus of the water glass is 3.1-3.4, the content of silicon dioxide is ≥ 26%, and the content of sodium oxide is ≥ 8.2%. The specification of the purity of the sodium hydroxide is chemically pure, and the purity is ≥ 99%.

[0056] Each raw material component and content used in the preparation of humidity-conditioning material in table 2 embodiment 2

[0057]

[0058] The composite geopolymer lightweight humidity-controlling material described above in this embodiment is prepared by the following method, including the following steps:

[0059] 1) Diss...

Embodiment 3

[0068] A composite geopolymer lightweight humidity-conditioning material of this embodiment, the humidity-conditioning material is prepared from the raw material components in the following Table 3, wherein: the average particle size of the metakaolin is 10 μm; the modified Diatomaceous earth is made of calcium chloride (CaCl 2 ) is prepared by modifying diatomite;

[0069] The modulus of the activator is 1.2 to 1.6;

[0070] The modulus of the water glass is 3.1-3.4, the content of silicon dioxide is ≥ 26%, and the content of sodium oxide is ≥ 8.2%. The specification of the purity of the sodium hydroxide is chemically pure, and the purity is ≥ 99%.

[0071] Each raw material component and content used in the preparation of the humidity-conditioning material in the embodiment 3 of table 3

[0072]

[0073] The composite geopolymer lightweight humidity-controlling material described above in this embodiment is prepared by the following method, including the following steps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com