Preparation method of colorful cycle tire tread rubber made of high-filling environment-friendly high-strength tire reclaimed rubber

A technology for reclaimed rubber and rickshaw tires, applied in the field of preparation of colored rickshaw tread rubber, can solve the problems of narrow molecular chain distribution, poor self-adhesion, easy scorch of rubber materials, etc., achieves less tendency of vulcanization reversion, and improves tire performance. , to avoid the effect of rubber scorch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

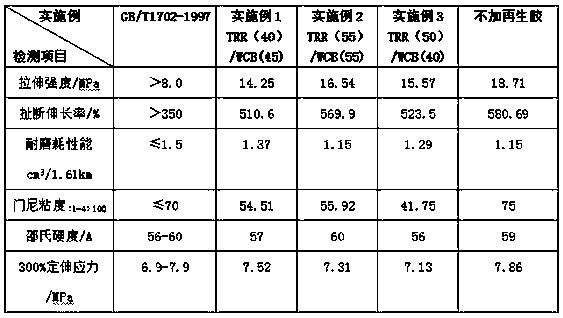

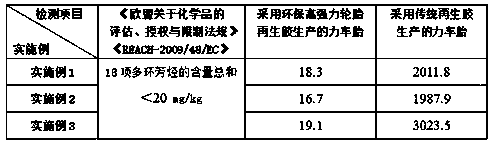

Embodiment 1

[0031] The formula of a kind of colored rickshaw tread rubber that is highly filled with environmentally friendly and high-strength tire reclaimed rubber is as follows:

[0032] Various raw materials and their mass parts are:

[0033] Natural rubber (NR)………… 60

[0034] Butadiene rubber (SBR)…………… 40

[0035] Environmentally friendly high-strength tire reclaimed rubber (TRR)... 40

[0036] White carbon black ……………… 45

[0037] Pine tar………………… 5.0

[0038] Vulcanizing agent S 8 …………… 2.5

[0039] Accelerator M…………… 2.0

[0040] Accelerator D…………… 1.0

[0041] Triethanolamine……… 2.0

[0042] Active agent ZnO………… 5.0

[0043] Active agent SA……… 3.0

[0044] Antiaging agent 2246……… 1.0

[0045] Paraffin……… 1.0

[0046] Its preparation method, carry out as follows:

[0047] At room temperature, 14.5 Kg of NR and 9.6 Kg of BR were first plasticized using an open mill XK-450 (capacity of 50Kg), and then the NR and BR plasticized rubbers were combined and pressed, and 9.6...

Embodiment 2

[0050] The formula of a kind of colored rickshaw tread rubber that is highly filled with environmentally friendly and high-strength tire reclaimed rubber is as follows:

[0051] Various raw materials and their mass parts are:

[0052] Natural rubber (NR) …………… 60

[0053] Butadiene rubber (SBR)…………… 40

[0054] Environmental protection high strength tire reclaimed rubber (TRR) 55

[0055] White carbon black……………… 55

[0056] Pine tar………………… 5.0

[0057] Vulcanizing agent S 8 …………… 2.5

[0058] Accelerator M…………… 2.0

[0059] Accelerator D…………… 1.0

[0060] Triethanolamine……… 2.0

[0061] Active agent ZnO………… 5.0

[0062] Active agent SA……… 3.0

[0063] Antiaging agent 2246……… 1.0

[0064] Paraffin……… 1.0

[0065] Its preparation method, carry out as follows:

[0066]Mix 25.4 Kg NR16.9 Kg BR with the internal mixer (filling capacity 140.63 Kg, filling factor 0.7), respectively, combine the NR and BR plasticized rubbers, and add 23.3 Kg of environmentally friendly h...

Embodiment 3

[0069] The formula of a kind of colored rickshaw tread rubber that is highly filled with environmentally friendly and high-strength tire reclaimed rubber is as follows:

[0070] Various raw materials and their mass parts are:

[0071] Natural rubber (NR)………… 60

[0072] Butadiene rubber (SBR)…………… 40

[0073] Environmentally friendly high-strength tire reclaimed rubber (TRR)... 50

[0074] White carbon black……………… 40

[0075] Pine tar………………… 5.0

[0076] Vulcanizing agent S 8 …………… 2.5

[0077] Accelerator M…………… 2.0

[0078] Accelerator D…………… 1.0

[0079] Triethanolamine……… 2.0

[0080] Active agent ZnO………… 5.0

[0081] Active agent SA……… 3.0

[0082] Antiaging agent 2246……… 1.0

[0083] Paraffin……… 1.0

[0084] Its preparation method, carry out as follows:

[0085] At room temperature, 18.4 Kg of NR and 12.2 Kg of BR were first plasticized with an open mill XK-550 (capacity of 65Kg), and then the NR and BR plasticized rubbers were combined and pressed, and 15.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com