Circuit board substrate with good heat dissipation and preparation method thereof

A board substrate and heat dissipation technology, which is applied in the field of circuit board substrate and its preparation, can solve problems affecting the service life and performance of electronic products, affecting the working stability of devices, and circuit boards hindering heat, etc., achieving high strength and good stability , good cooling performance

Inactive Publication Date: 2019-01-22

张玉锦

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing circuit board substrate generally has the problem of poor heat dissipation. In electronic products, the integration of electronic circuits is getting higher and higher, and the heat generated during the operation of the chip is difficult to release. The accumulation of heat will affect the working stability of the device. , the existing circuit board will hinder the dissipation of heat, affecting the service life and performance of electronic products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

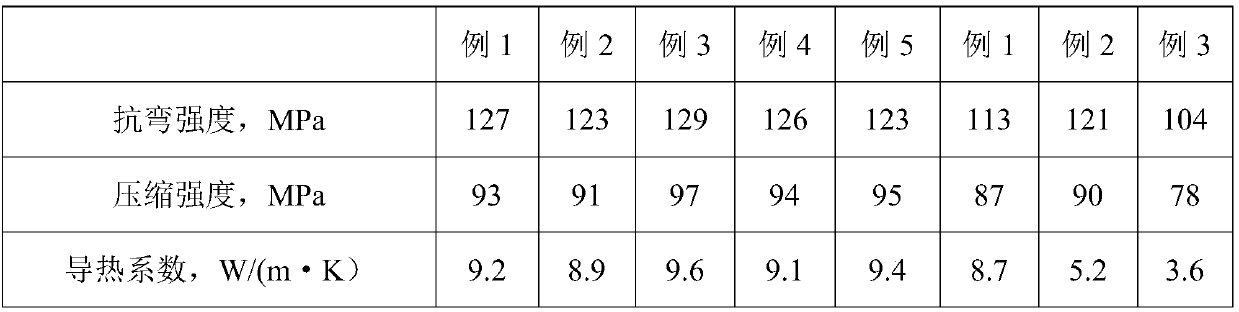

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a circuit board substrate with good heat dissipation. The circuit board substrate comprises the following raw materials in parts by weight: 60-80 parts of bisphenol A type epoxy resin, 20-30 parts of polytetramethylene adipamide, 10-20 parts of silicone resin, 10-20 parts of phenolic resin, 3-6 parts of glass fiber, 5-10 parts of calcium carbonate, 8-16 parts of silicon carbide, 3-6 parts of graphene, 5-10 parts of diamond micro-powder, 10-20 parts of polyethylene glycol, 2-6 parts of 2-hydroxy-4-methoxybenzophenone, 1-2 parts of N, N-dimethylformamide, 2-4 parts of di-2,4-dichlorobenzoyl peroxide, 1-2 parts of an antioxidant, and 3-5 parts of copper foil. The invention also discloses a preparation method of the circuit board substrate with good heat dissipation. The circuit board substrate has good heat dissipation performance under the cooperation effect of various raw materials, and ensures the service life and performance of the electronic products.

Description

technical field The invention relates to the field of electronic technology, in particular to a circuit board substrate with good heat dissipation and a preparation method thereof. Background technique Substrate is the basic material for manufacturing circuit boards. In general, substrates are copper-clad laminates. Single- and double-sided printed boards are manufactured on the substrate material-copper-clad laminates, selectively processing holes, Electroless copper plating, electroplating copper, etching and other processing to obtain the required circuit pattern, which has three functions of conduction, insulation and support, the performance, quality, processability in manufacturing, manufacturing cost, and manufacturing level of printed boards, etc. , depends largely on the substrate material. The existing circuit board substrate generally has the problem of poor heat dissipation. In electronic products, the integration of electronic circuits is getting higher and hi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L63/00C08L77/06C08L83/04C08L61/06C08L71/02C08K13/04C08K7/14C08K3/26C08K3/34C08K3/04H05K1/03B32B27/38B32B15/20B32B15/092

CPCB32B15/092B32B15/20B32B27/38B32B2307/302B32B2307/50B32B2307/546B32B2457/00C08K2003/265C08L63/00C08L2203/20C08L2205/035H05K1/0366H05K1/0373C08L77/06C08L83/04C08L61/06C08L71/02C08K13/04C08K7/14C08K3/26C08K3/34C08K3/042

Inventor 张玉锦

Owner 张玉锦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com