Water-based wall coating and preparation method thereof

A wall and paint technology, applied in the field of water-based wall paint and its preparation, can solve the problems of poor thermal insulation performance of water-based wall paint, and achieve excellent heat insulation effect, strong infrared radiation function, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] A preparation method of water-based wall paint, comprising the steps of:

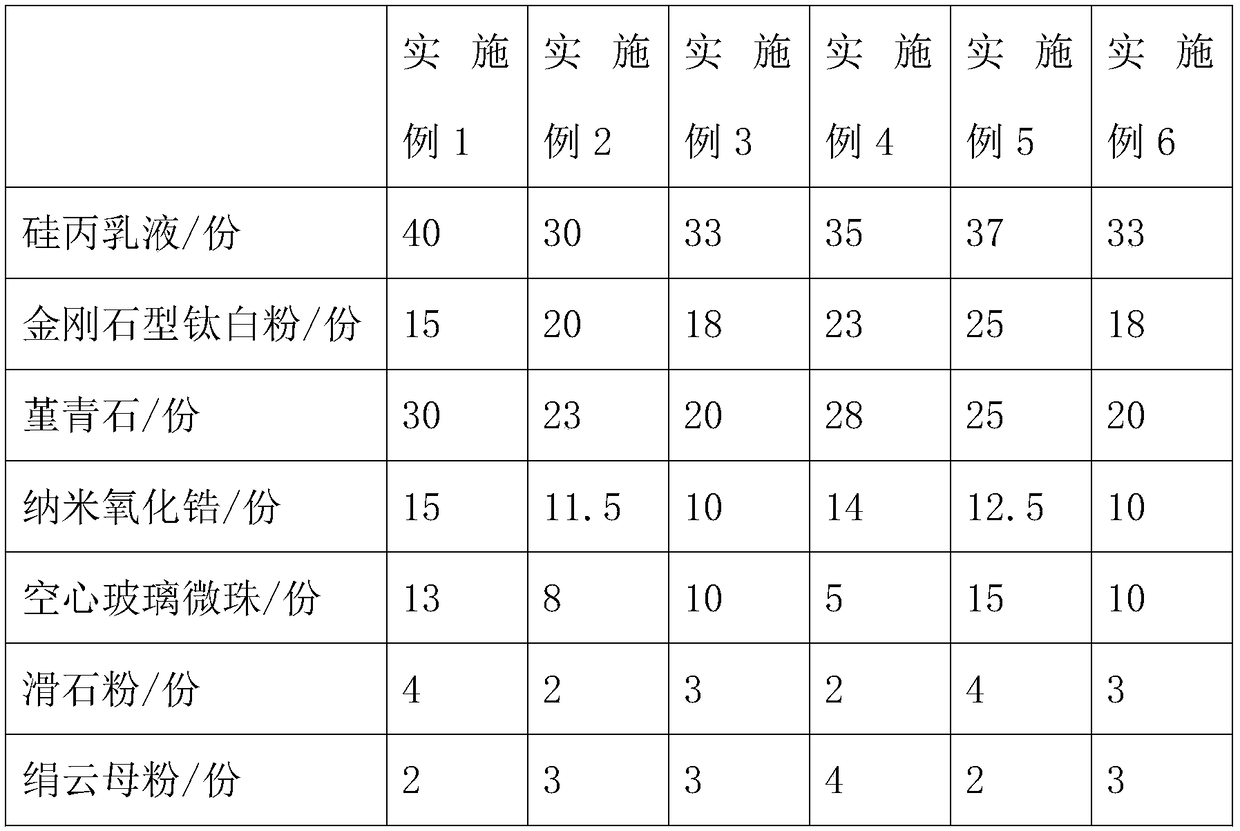

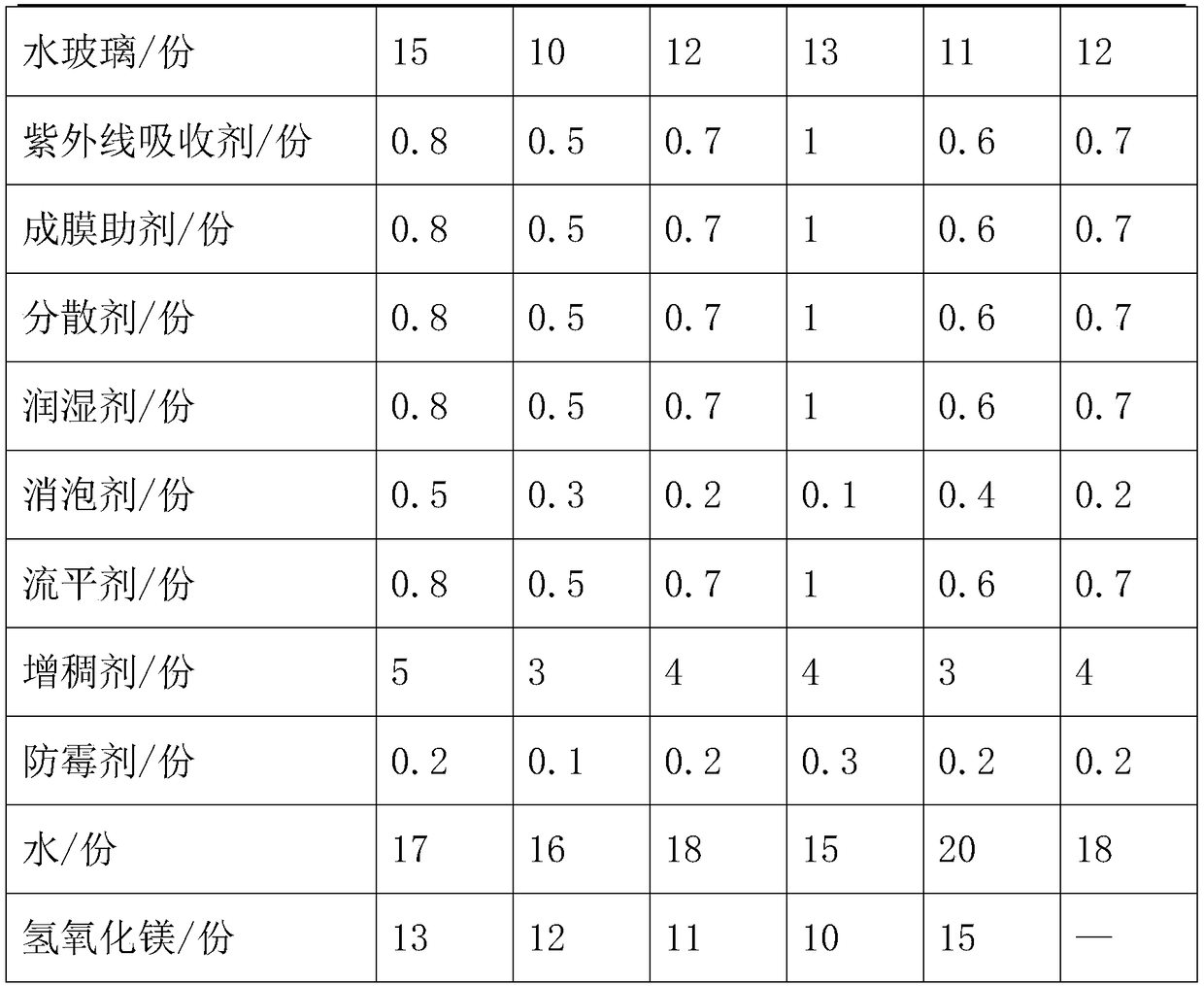

[0056]Step 1: According to parts by weight, weigh silicon-acrylic emulsion, titanium dioxide, cordierite, nano-zirconia, hollow glass microspheres, talcum powder, sericite powder, water glass, ultraviolet absorber, film-forming aid, dispersant, Wetting agent, defoamer, leveling agent, thickener, antifungal agent, water, magnesium hydroxide;

[0057] Step 2: Add titanium dioxide, cordierite, nano zirconia, hollow glass microspheres, talcum powder, sericite powder, water glass, ultraviolet absorber, dispersant, wetting agent, half weight of defoamer, anti Mold agent and magnesium hydroxide, stir evenly;

[0058] Step 3: Add silicone-acrylic emulsion, film-forming aid, the other half of the weight of defoamer and leveling agent, and stir evenly;

[0059] Step 4: Add thickener, stir evenly and discharge.

Embodiment 3

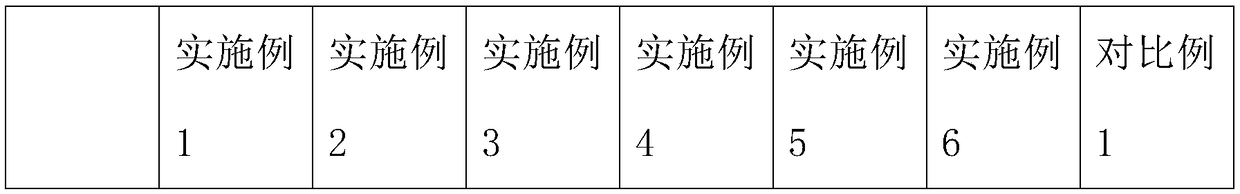

[0092] The thermal insulation performance of Example 3 is better than that of Comparative Examples 2 and 3, and the thermal insulation performance of Comparative Example 4 is worse than that of Comparative Examples 2 and 3. It can be seen that both cordierite and nano-zirconia can improve the thermal insulation performance of the present invention. In addition, the joint addition of cordierite and nano-zirconia can improve the thermal insulation performance of the present invention more than the sum of the improvement effects of cordierite and nano-zirconia alone on the thermal insulation performance of the present invention. Therefore, cordierite and nano-zirconia can produce a synergistic effect in the present invention and promote the improvement of the thermal insulation performance of the present invention.

[0093] The weather resistance and flame retardancy of Example 3 are similar to those of Comparative Examples 2 and 3, and the weather resistance and flame retardancy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com