Ternary MOF nanosheet array material as well as preparation method and application thereof

A nanosheet array, hydrothermal reaction technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of negative environment and resources, many preparation steps, low catalytic activity, etc., to achieve low production cost, dispersed The effect of good performance and large active surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a ternary MOF nanosheet array material, the preparation method comprising the following steps:

[0035] S1: Put the nickel sheet with impurities on the surface into hydrochloric acid, ethanol and double distilled water in sequence for ultrasonic cleaning for 15 minutes respectively;

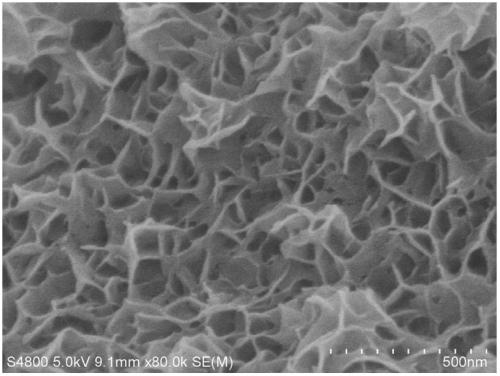

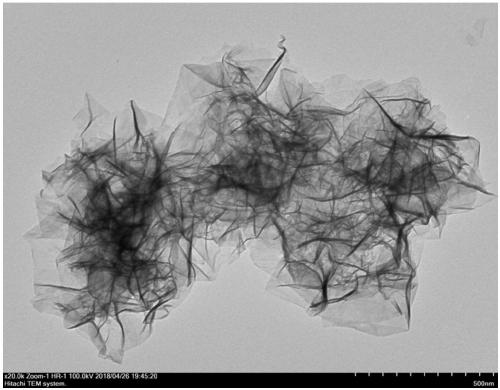

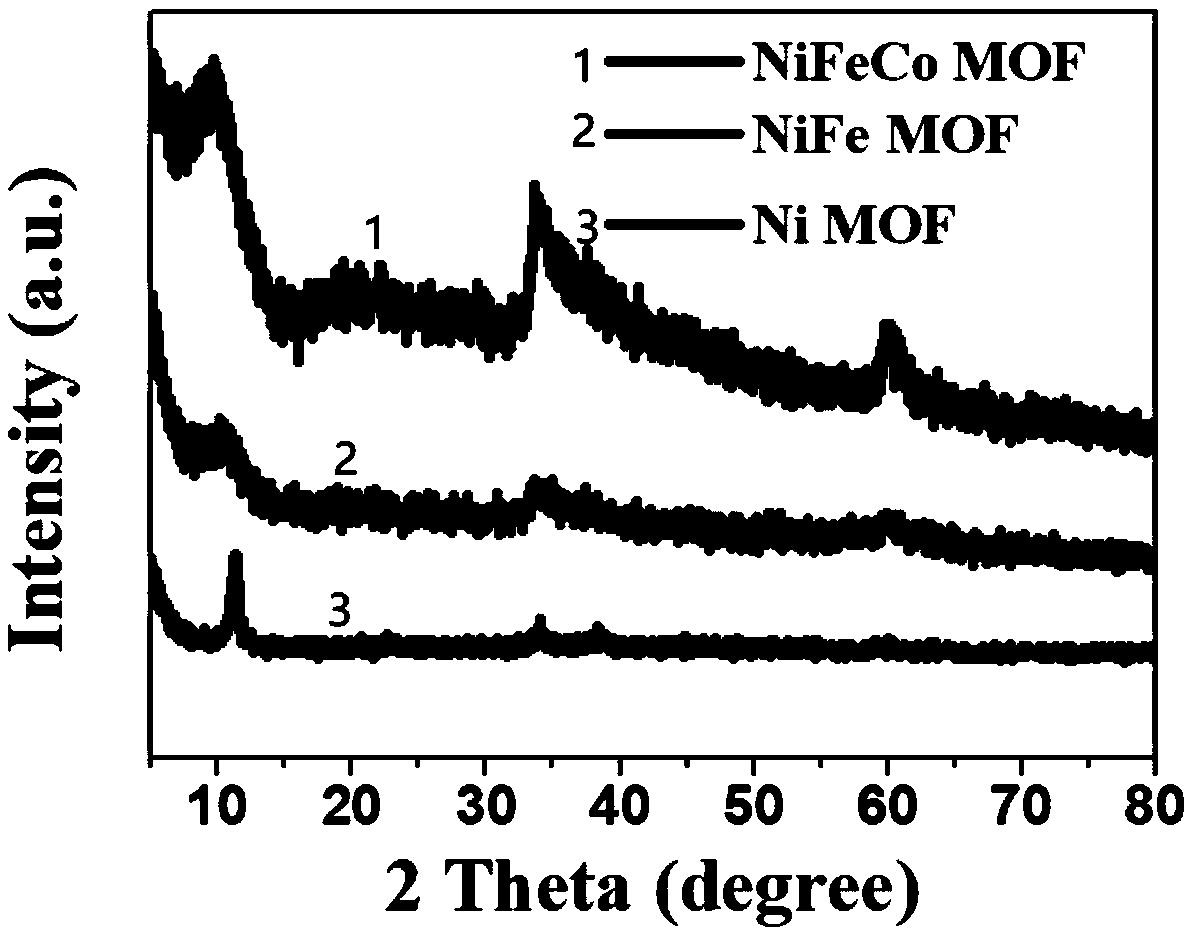

[0036] S2: Dissolve 1mmol of nickel salt, 0.2mmol of iron salt, 0.02mmol of cobalt salt and 4mmol of organic ligand 2-methylimidazole in 35mL of methanol and pour into the reaction kettle, immerse the treated foam nickel into the mixture, and tighten the kettle Cover, react at 150°C for 4h, take out the reactor and cool it down to room temperature naturally, rinse with ethanol and double distilled water, and dry at 60°C overnight to obtain a ternary iron-cobalt-nickel MOF nanosheet array material loaded on nickel foam, The ternary MOF nanosheet material (NiFeCo-ZIF / NF) loaded on nickel foam is obtained, and its SEM image is as follows figure 1 As shown, the TEM ima...

Embodiment 2

[0041] A preparation method of a ternary MOF nanosheet array material, the preparation method comprising the following steps:

[0042] S1: Put the nickel sheet with impurities on the surface into hydrochloric acid, ethanol and double distilled water for 15 minutes respectively for ultrasonic cleaning;

[0043] S2: Dissolve 1mmol of nickel salt, 0.25mmol of iron salt, 0.02mmol of cobalt salt and 4mmol of organic ligand 2-methylimidazole in 35mL of methanol and pour it into the reaction kettle, immerse the treated foamed nickel into the mixture, and tighten the kettle Cover, react at 160°C for 4 hours, take out the reaction vessel and cool it down to room temperature naturally, rinse with ethanol and double distilled water, and dry at 60°C overnight to obtain a ternary iron-cobalt-nickel MOF nanosheet array material loaded on nickel foam. The ternary MOF nanosheet material (NiFeCo-ZIF / NF) loaded on the nickel foam is obtained, and its SEM image is as follows Figure 7 shown.

[...

Embodiment 3

[0046] A preparation method of a ternary MOF nanosheet array material, the preparation method comprising the following steps:

[0047] S1: Put the nickel sheet with impurities on the surface into hydrochloric acid, ethanol and double distilled water for 15 minutes respectively for ultrasonic cleaning;

[0048] S2: Dissolve 1mmol of nickel salt, 0.2mmol of iron salt, 0.03mmol of cobalt salt and 4mmol of organic ligand 2-methylimidazole in 35mL of methanol and pour it into the reaction kettle, immerse the treated foamed nickel into the mixture, and tighten the kettle Cover, react at 160°C for 6h, take out the reactor and cool it down to room temperature naturally, rinse with ethanol and double distilled water, and dry at 60°C overnight to obtain a ternary iron-cobalt-nickel MOF nanosheet array material loaded on nickel foam, The ternary MOF nanosheet material (NiFeCo-ZIF / NF) loaded on nickel foam is obtained, and its SEM image is as follows Figure 8 shown.

[0049] The applic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com