Fullerene aquatic feed additive, preparing method thereof and feed

A technology of aquatic feed and fullerene, applied in the field of feed, can solve the problems of reducing the body's anti-stress and disease resistance, excessive fat deposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

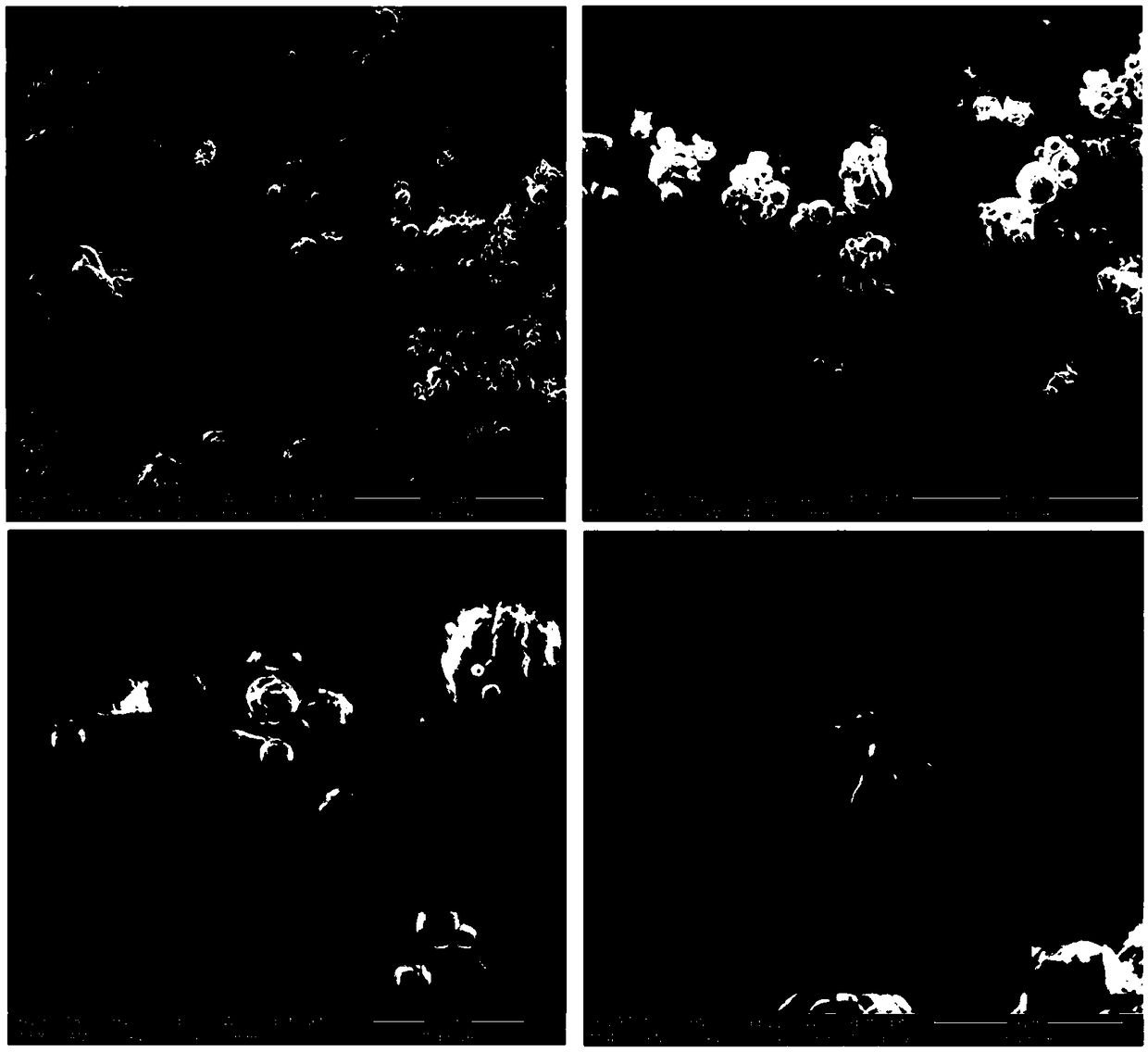

Image

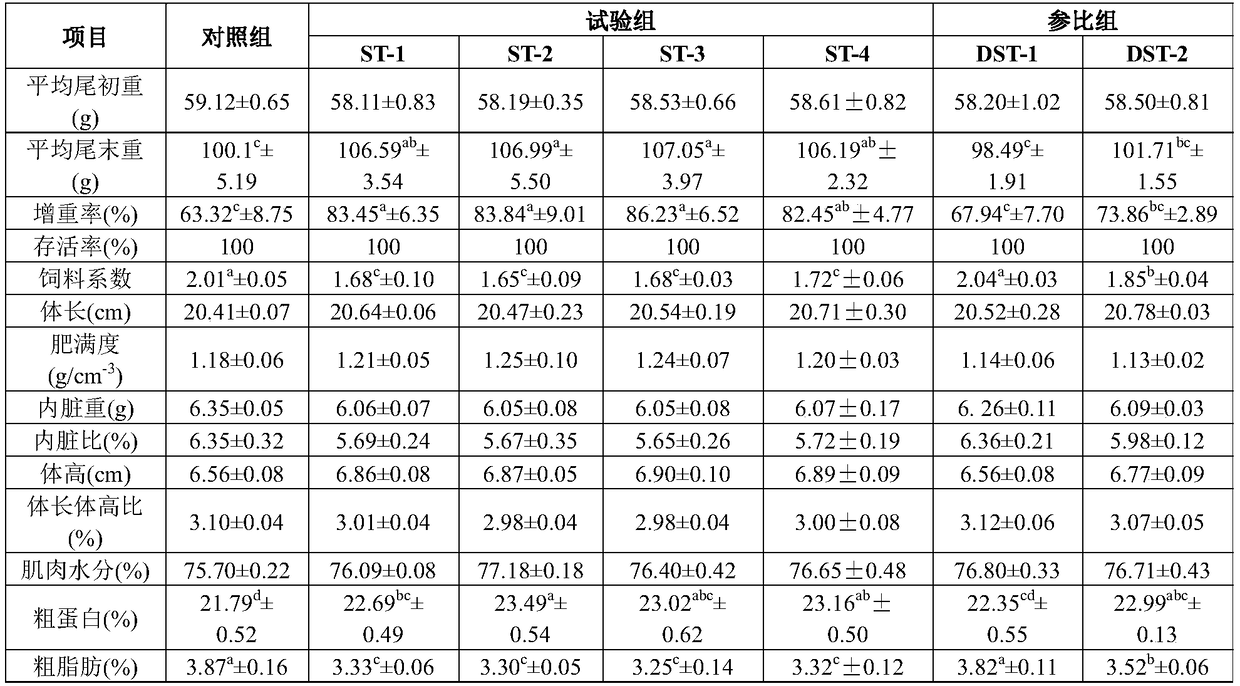

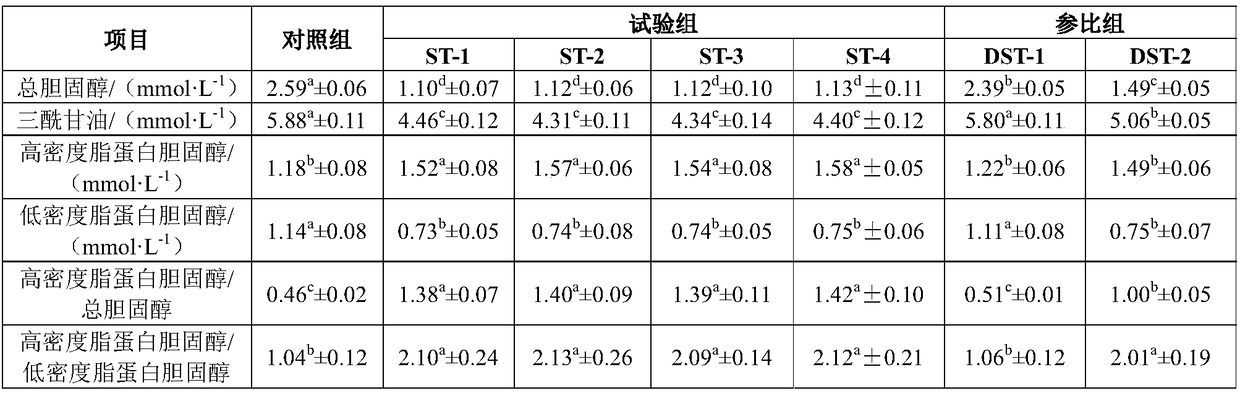

Examples

preparation example 1

[0056] Preparation Example 1: Preparation of Fullerene Oil Solution

[0057] Accurately weigh 100g of nutritional compound oil (the weight ratio of olive oil, linseed oil, and Xanthania oil is 5:3:2) and 0.3g of fullerene C 60 , pour the above raw materials into a ball mill tank for ball milling, transfer the ball milled product to a centrifuge bottle for centrifugation at 8000r / min for 1h, and pass the centrifuged product through a filter device (0.5μm) for sterilizing treatment, after sterilizing, the obtained The product is fullerene nutrient compound oil solution.

preparation example 2

[0058] Preparation Example 2: Preparation of fullerene oil solution

[0059] Accurately weigh 100g olive oil and 0.15g fullerene C 60 , pour the above raw materials into a ball mill tank for ball milling, transfer the ball milled product to a centrifuge bottle for centrifugation at 7000r / min for 1.5h, and pass the centrifuged product through a filter device (0.5μm) for sterilizing treatment, after sterilizing The resulting product is a fullerene olive oil solution.

preparation example 3

[0060] Preparation Example 3: Preparation of Fullerene Oil Solution

[0061] Accurately weigh 100g sea buckthorn seed oil and 0.12g fullerene C 70 , pour the above raw materials into a ball mill tank for ball milling, transfer the ball milled product to a centrifuge bottle for centrifugation at 6500r / min for 2h, and pass the centrifuged product through a filter device (0.5μm) for sterilizing treatment, after sterilizing, the obtained The product is fullerene seabuckthorn oil solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com