Barium and strontium scale removing agent and preparation method thereof

A descaling agent, strontium scale technology, applied in descaling and water softening, chemical instruments and methods, special treatment targets, etc. Strong ability and good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

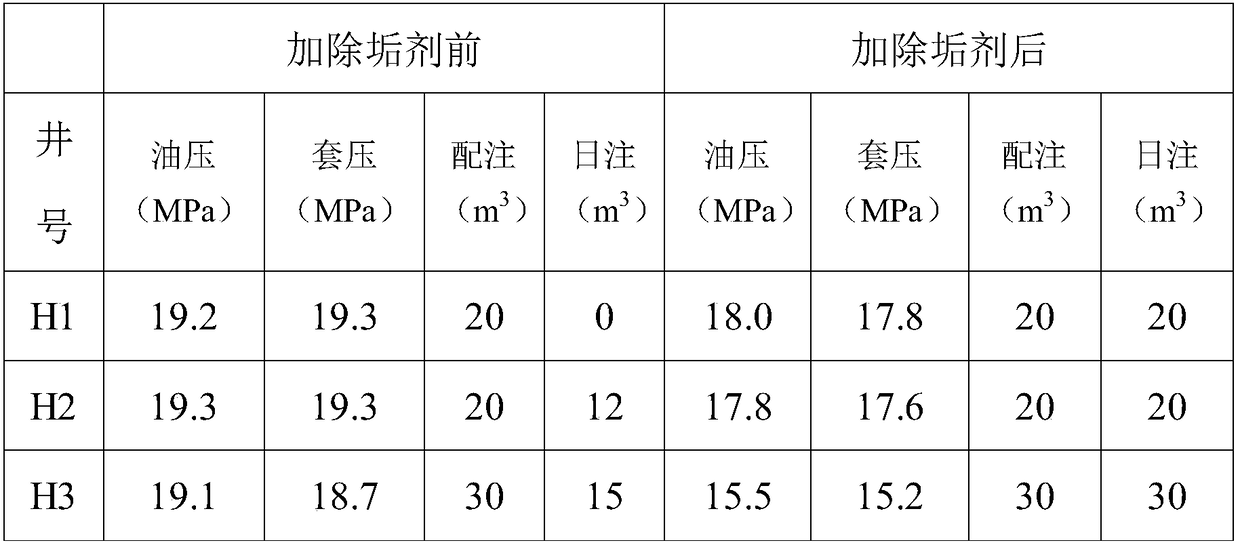

Examples

Embodiment 1

[0043] A barium strontium scale remover is made up of the following raw materials in weight percentage:

[0044] Hydrochloric acid 10-15%;

[0045] Hydrofluoric acid 2-5%;

[0046] Chelating agent 2-5%;

[0047] Anti-scaling agent 2-5%;

[0048] Corrosion inhibitor 0.5% ~ 1%;

[0049] Surfactant 0.5% ~ 1%;

[0050] Synergist 0.1-0.3%;

[0051] Regulator 0.2% ~ 0.4%;

[0052] The remainder is water.

[0053] The preparation method of the barium strontium scale remover comprises the following steps: successively take hydrochloric acid, hydrofluoric acid, chelating agent, antiscalant, corrosion inhibitor, surfactant, synergist and water of formula quantity, place in In a beaker, stir and raise the temperature to 60-70°C, add the prescribed amount of solid sodium hydroxide, adjust the pH of the solution to 7-8, and obtain the descaling agent.

[0054] The descaling agent of the present invention can effectively remove barium and strontium scales that are insoluble in acid ...

Embodiment 2

[0056] On the basis of Example 1, the hydrochloric acid and hydrofluoric acid are commercially available chemically pure or industrially pure.

[0057] The chelating agent is one of diethylenetriaminepentapentaacetic acid and methacryloyl ethyl betaine; preferably diethylenetriaminepentapentaacetic acid, and the scale dissolving ability of said diethylenetriaminepentapentaacetic acid can reach 10.2g / L or so; the antiscalant is an organic phosphoric acid type antiscalant, preferably polyamino polyether methylene phosphoric acid with better calcium tolerance and dispersibility. The chelating agent and the anti-scaling agent have obvious solubility-limiting effects, and improve the tolerance of calcium, barium, strontium and other ions.

[0058] The corrosion inhibitor is composed of ethanol, polyepoxysuccinic acid, triethylenetriamine, cyclohexanone, and octynyl alcohol in a mass ratio of 6:2:2:4:1, at 90°C to 100°C Stir at the reaction temperature for 1 hour to prepare a solut...

Embodiment 3

[0062] A barium strontium scale remover, which is composed of the following raw materials in weight percentage: 12% hydrochloric acid; 3% hydrofluoric acid; 3% chelating agent; 3% scale inhibitor; 0.5% corrosion inhibitor; 0.5% surfactant; 0.1% synergist; 0.2% regulator; the rest is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com