Modified polyphenylene ether high molecular polymer, high molecular film and corresponding preparation method

A high-molecular polymer and high-molecular film technology, which is applied in the field of modified polyphenylene ether high-molecular polymers, can solve the problem of high-frequency signal transmission and high-speed digitalization, and the inability of flexible circuit boards to achieve high-frequency signal transmission impedance matching And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preferred embodiment of the present invention also provides a method for preparing the above-mentioned modified polyphenylene ether polymer, which includes the following steps:

[0034] Step S1, uniformly mixing a polyphenylene ether polymer, a reactive reactant and a solvent to prepare a resin composition. In the resin composition, the weight ratio of the polyphenylene ether polymer to the active reactant is 1:10˜50:1. The solvent only needs to dissolve the polyphenylene ether polymer and the active reactants. In this embodiment, the viscosity of the resin composition is 40000cps˜60000cps.

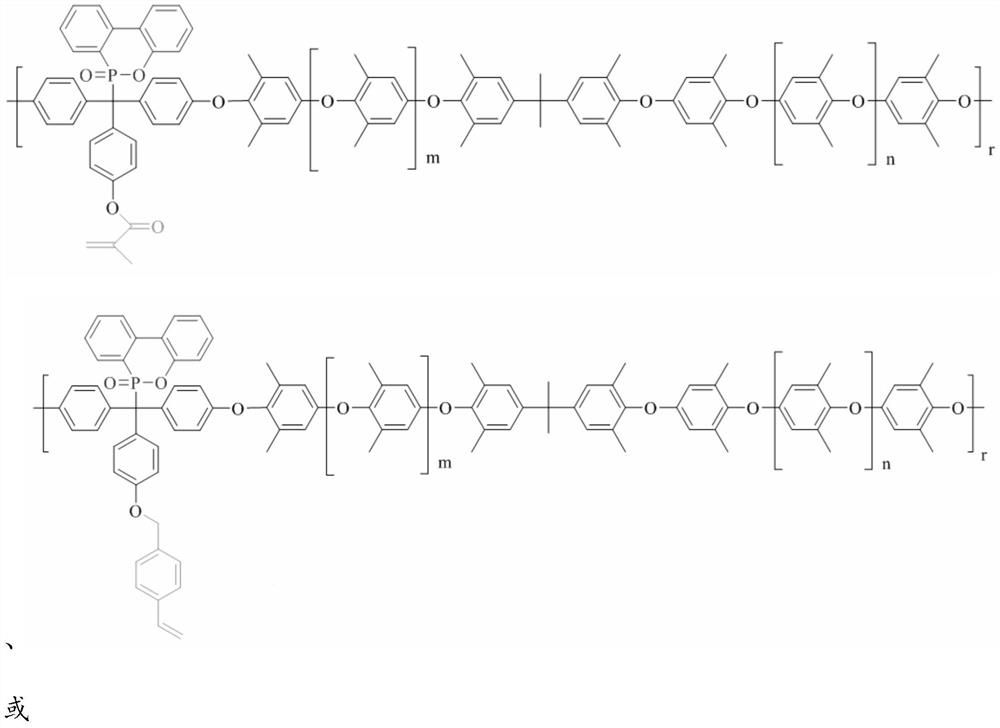

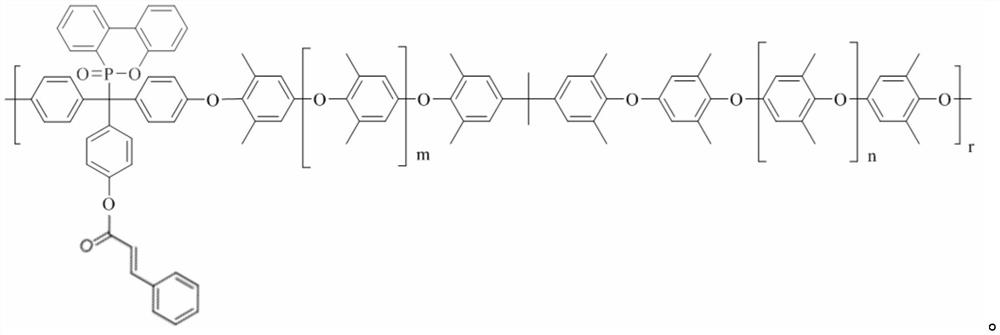

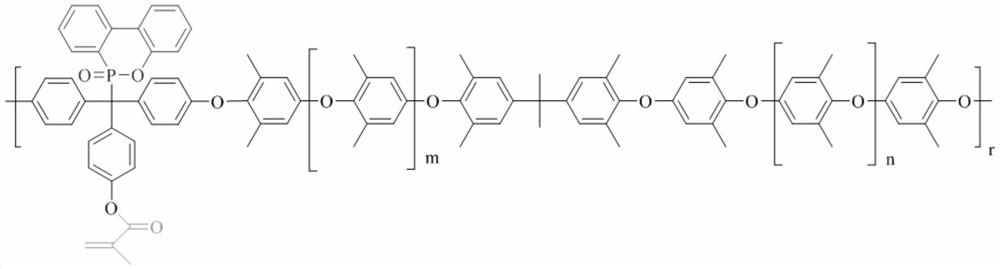

[0035] The chemical structural formula of the polyphenylene ether polymer is

[0036]

[0037] The active reactant may be selected from but not limited to one of 2-methacrylic anhydride, 4-chloromethylstyrene and trans-cinnamoyl chloride.

[0038] In this embodiment, the solvent is N,N-dimethylacetamide (DMAc). In other embodiments, the solvent may also be other organic so...

Embodiment 1

[0057] Add 60g of 4,4'-difluorobenzophenone and 71g of 4,4'-difluorobenzophenone successively in the first reaction flask. The polyphenylene ether copolymer, 77g of potassium carbonate, 30mL of xylene and 393.6g of N,N-dimethylacetamide were stirred and dissolved, and then heated at 130 degrees Celsius for 12 hours in a nitrogen atmosphere to prepare the chemical structural formula: of the first product.

[0058]Add 50g of the first product and 23.6g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO, the chemical formula is ), 102.7g of phenol and 0.9g concentration of 97% sulfuric acid and stirring and dissolving, then heated at 140 degrees centigrade in nitrogen atmosphere for 12 hours to prepare the chemical structural formula as

[0059] polyphenylene ether polymers.

[0060] Add 10g of the above-mentioned polyphenylene ether polymer, 3.5g of 2-methacrylic anhydride, 0.1g of sodium acetate and 100mL of N,N-dimethylacetamide to the third reaction flask in s...

Embodiment 2

[0062] Add 10g of the polyphenylene ether polymer in Example 1, 3.5g of 4-chloromethylstyrene, 0.1g of sodium acetate and 100mL of N,N-dimethylacetamide into the reaction flask in sequence and Stir and dissolve, then heat at 80 degrees Celsius for 12 hours in a nitrogen atmosphere to prepare the chemical structural formula as

[0063] modified polyphenylene ether polymers. The viscosity of the modified polyphenylene ether polymer is 51s000cps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com