CPE (Chlorinated Polyethylene)/NBR (Nitrile Butadiene Rubber) composite oil resistant car ventilation hose and preparation method thereof

An automobile and oil-resistant technology, applied in the field of CPE/NBR composite oil-resistant automobile ventilation hose and its preparation, can solve the problems of narrow application range of polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

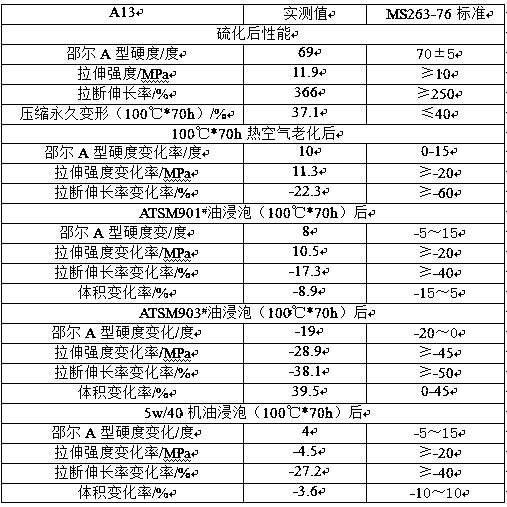

Embodiment 1

[0028] Raise the temperature of the open mill to 70°C, adjust the roller distance to the minimum, add chlorinated polyethylene CPE and masticate until there are no particles, and the mastication will be uniform; then wrap the evenly masticated CPE on the open mill (roller temperature 50 ℃), followed by adding magnesium oxide, barium stearate, carbon black (grade N330), silicon powder, plasticizer (dioctyl phthalate DOP), antioxidant RD, nitrile rubber NBR (grade 1052) , vulcanizing agent TCY, and cross-linking agent TAIC-70 were mixed evenly (at 170°C for 20 minutes), and the film was released; finally, the rubber was parked for 24 hours and then re-milled to form the automobile vent hose A1; among them, CPE, NBR , carbon black, silicon powder, plasticizer, magnesium oxide, anti-aging agent, barium stearate, vulcanizing agent, cross-linking agent in a weight ratio of 70:30:35:55:25:10:1:3:3 :6.

Embodiment 2

[0030] According to the method described in Example 1, the automobile breather rubber hose A2 is obtained, the difference is that CPE, NBR, carbon black, silicon powder, plasticizer, magnesium oxide, anti-aging agent, barium stearate, vulcanizing agent, crosslinking aid The weight ratio of the agent is 70:28:33:53:23:8:0.8:2.8:2.8:5.

Embodiment 3

[0032] According to the method described in Example 1, the automobile breather rubber hose A3 is obtained, the difference is that CPE, NBR, carbon black, silicon powder, plasticizer, magnesium oxide, anti-aging agent, barium stearate, vulcanizing agent, crosslinking aid The weight ratio of the agent is 70:32:37:57:27:12:1.2:3.2:3.2:6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com