Oxidized graphene and waste vegetable oil composite modified warm mix asphalt and preparation method

A technology for waste edible oil and warm mix asphalt, which is applied in the fields of climate change adaptation, building insulation materials, building components, etc., can solve the failure to improve the low temperature performance of matrix asphalt, unfavorable energy saving, emission reduction and environmental protection, and mixing construction temperature requirements. High problems, to achieve the effect of good heat resistance, high flash point and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

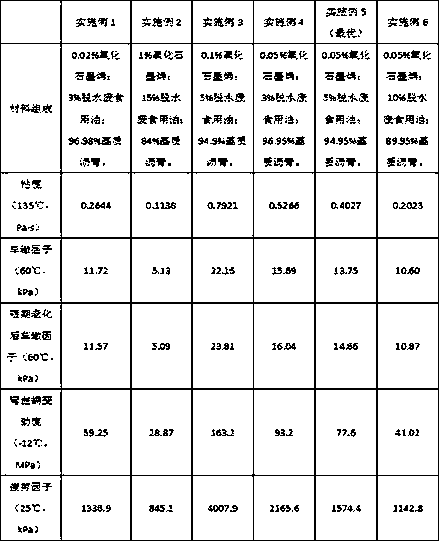

Embodiment 1

[0047] A modified warm-mix asphalt compounded with graphene oxide and waste cooking oil, composed of the following components in terms of mass fraction:

[0048] 0.02% graphene oxide;

[0049] 3% dehydrated waste cooking oil;

[0050] 96.98% base bitumen.

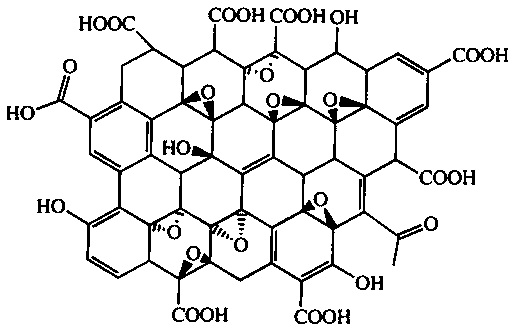

[0051] The graphene oxide is prepared by the Hummers method, the layer spacing is 0.7-1.2nm, and the specific surface area is 2100-2600m 2 / g. The dehydrated waste cooking oil is derived from kitchen waste oil, its main component is triglyceride, and its oxygen content is about 40% to 50%. After the dehydration process, the water and volatile matter content is less than 0.2%. The base asphalt is selected from Esso 70# asphalt or Gaofu 70# asphalt.

[0052] The preparation method of the composite modified warm-mix asphalt based on graphene oxide and dehydrated waste cooking oil comprises the following preparation steps:

[0053] Step 1, heating the base asphalt, adding graphene oxide to the heated base asphalt, shearing ...

Embodiment 2

[0058] A modified warm-mix asphalt compounded with graphene oxide and waste cooking oil, composed of the following components in terms of mass fraction:

[0059] 1% graphene oxide;

[0060] 15% dehydrated waste cooking oil;

[0061] 84% base bitumen.

[0062] The preparation method of the composite modified warm-mix asphalt based on graphene oxide and dehydrated waste cooking oil comprises the following preparation steps:

[0063] Step 1, heating the base asphalt, adding graphene oxide to the heated base asphalt, shearing and stirring, to obtain graphene oxide modified asphalt;

[0064] Step 2, cooling the modified asphalt, adding dehydrated waste cooking oil to the cooled modified asphalt, and stirring to obtain composite modified warm mix asphalt.

[0065] The base pitch is heated to 160° C., the shear rate is 2000 r / min, the shear time is 25 min; the stirring time is 25 min.

[0066] In the step 2, the cooling temperature is 130° C., and the stirring time is 35 minutes....

Embodiment 3

[0068] A modified warm-mix asphalt compounded with graphene oxide and waste cooking oil, composed of the following components in terms of mass fraction:

[0069] 0.1% graphene oxide;

[0070] 5% dehydrated waste cooking oil;

[0071] 94.9% base bitumen.

[0072] The preparation method of the composite modified warm-mix asphalt based on graphene oxide and dehydrated waste cooking oil comprises the following preparation steps:

[0073] Step 1, heating the base asphalt, adding graphene oxide to the heated base asphalt, shearing and stirring, to obtain graphene oxide modified asphalt;

[0074] Step 2, cooling the modified asphalt, adding dehydrated waste cooking oil to the cooled modified asphalt, and stirring to obtain composite modified warm mix asphalt.

[0075] The base pitch is heated to 155° C., the shear rate is 2500 r / min, the shear time is 30 min; the stirring time is 30 min.

[0076] The cooling temperature is 128° C., and the stirring time is 43 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer spacing | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com