A method of using hydrogen to recover non-permeate gas to produce synthetic natural gas

A technology for synthesizing natural gas and non-permeable gas, applied in the field of non-permeable gas production of synthetic natural gas, can solve the problems of unfavorable methane equilibrium conversion, unreasonable economy, and high reaction temperature, achieve good economic and environmental benefits, low bed temperature, and easy temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

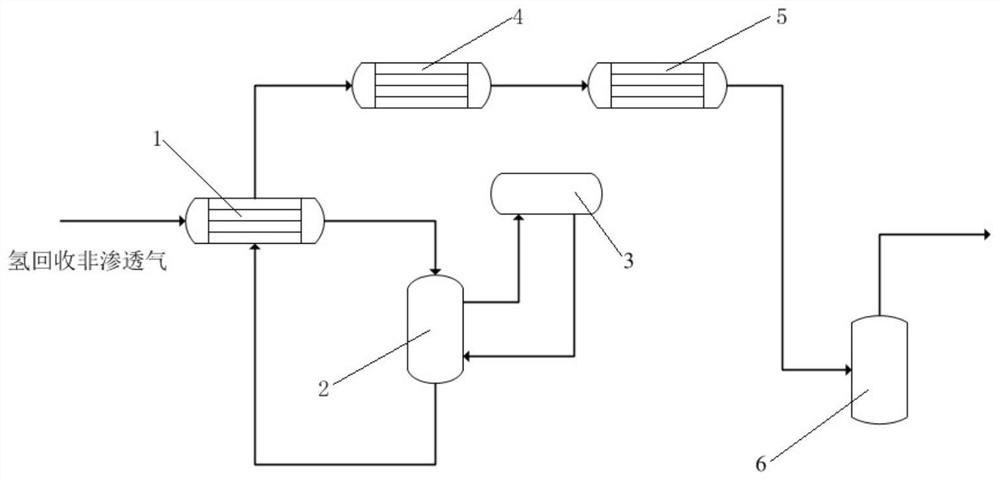

Image

Examples

Embodiment 1

[0028] In this embodiment, the method for producing synthetic natural gas by using hydrogen to recover non-permeable gas, the specific steps are: the non-permeable gas 6000Nm after methanol purge gas is recovered with hydrogen and rich in hydrogen 3 / h (containing volume fraction H 2 29% CO 5% CO 2 9.5%), enter the high-pressure one-stage isothermal methanation reactor through the gas-gas heat exchanger, and convert the H 2 , CO and CO 2 The reaction generates methane, and the synthesis gas exiting the isothermal methanation reactor is first preheated for the inlet gas, then sequentially passes through the desalted water preheater, and the circulating water cooler to cool down to about 40°C, and then enters the gas-liquid separator to separate liquid water After, can produce 4330Nm 3 / h of synthesis gas is sent to the natural gas pipeline.

Embodiment 2

[0030] In this embodiment, the method for producing synthetic natural gas by using hydrogen to recover non-permeable gas, the specific steps are: the non-permeable gas 4500Nm after the methanol purge gas is recovered by hydrogen and rich in hydrogen 3 / h (containing volume fraction H 2 35% CO 6% CO 2 10%), enter the high-pressure one-stage isothermal methanation reactor through the gas-gas heat exchanger, and convert the H 2 , CO and CO 2 The reaction generates methane, and the synthesis gas exiting the isothermal methanation reactor is first preheated for the inlet gas, then sequentially passes through the desalted water preheater, and the circulating water cooler to cool down to about 40°C, and then enters the gas-liquid separator to separate liquid water After, can produce 2990Nm 3 / h of synthesis gas is sent to the natural gas pipeline.

Embodiment 3

[0032] In this embodiment, the method for producing synthetic natural gas by using hydrogen to recover non-permeable gas, the specific steps are: the non-permeable gas 1000Nm after the methanol purge gas is recovered with hydrogen and rich in hydrogen 3 / h (containing volume fraction H 2 35%CO 8%CO 210%), enter the high-pressure first-stage isothermal methanation reactor through the gas-gas heat exchanger, and convert the H 2 , CO and CO 2 The reaction generates methane, and the synthesis gas exiting the isothermal methanation reactor is first preheated for the inlet gas, then sequentially passes through the desalted water preheater, and the circulating water cooler to cool down to about 40°C, and then enters the gas-liquid separator to separate liquid water After, can produce 657Nm 3 / h of synthesis gas is sent to the natural gas pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com