Method of recycling copper and cobalt from cobalt containing waste liquid of copper hydrometallurgy

A technology for recovering copper and waste liquid, applied in the field of hydrometallurgy, can solve the problems of inability to comprehensively recycle, consume large neutralizing agents, and treat a large amount of liquid, so as to reduce the amount of solution treatment, reduce the amount of neutralized slag, overcome the The effect of handling large volumes of liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

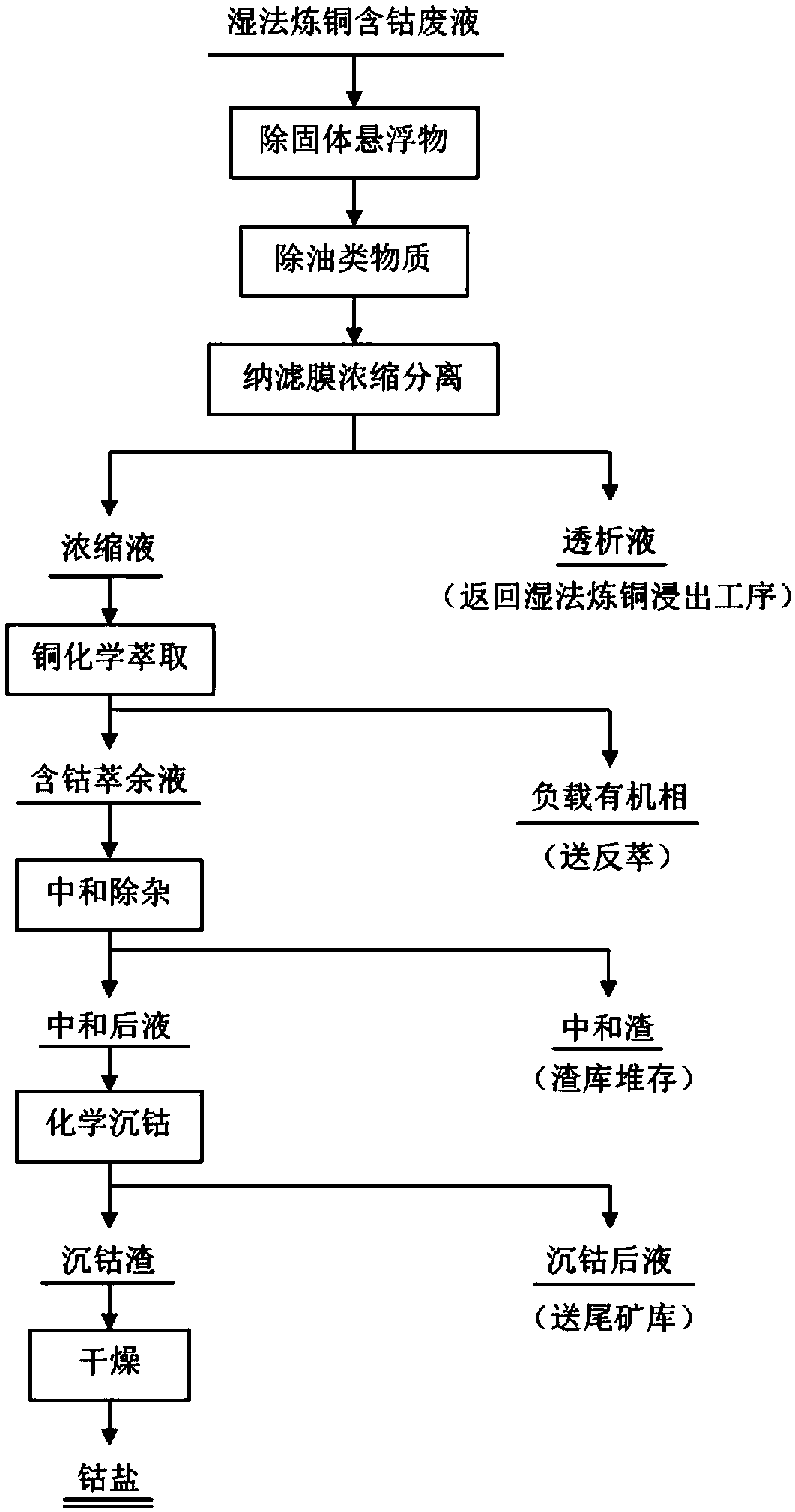

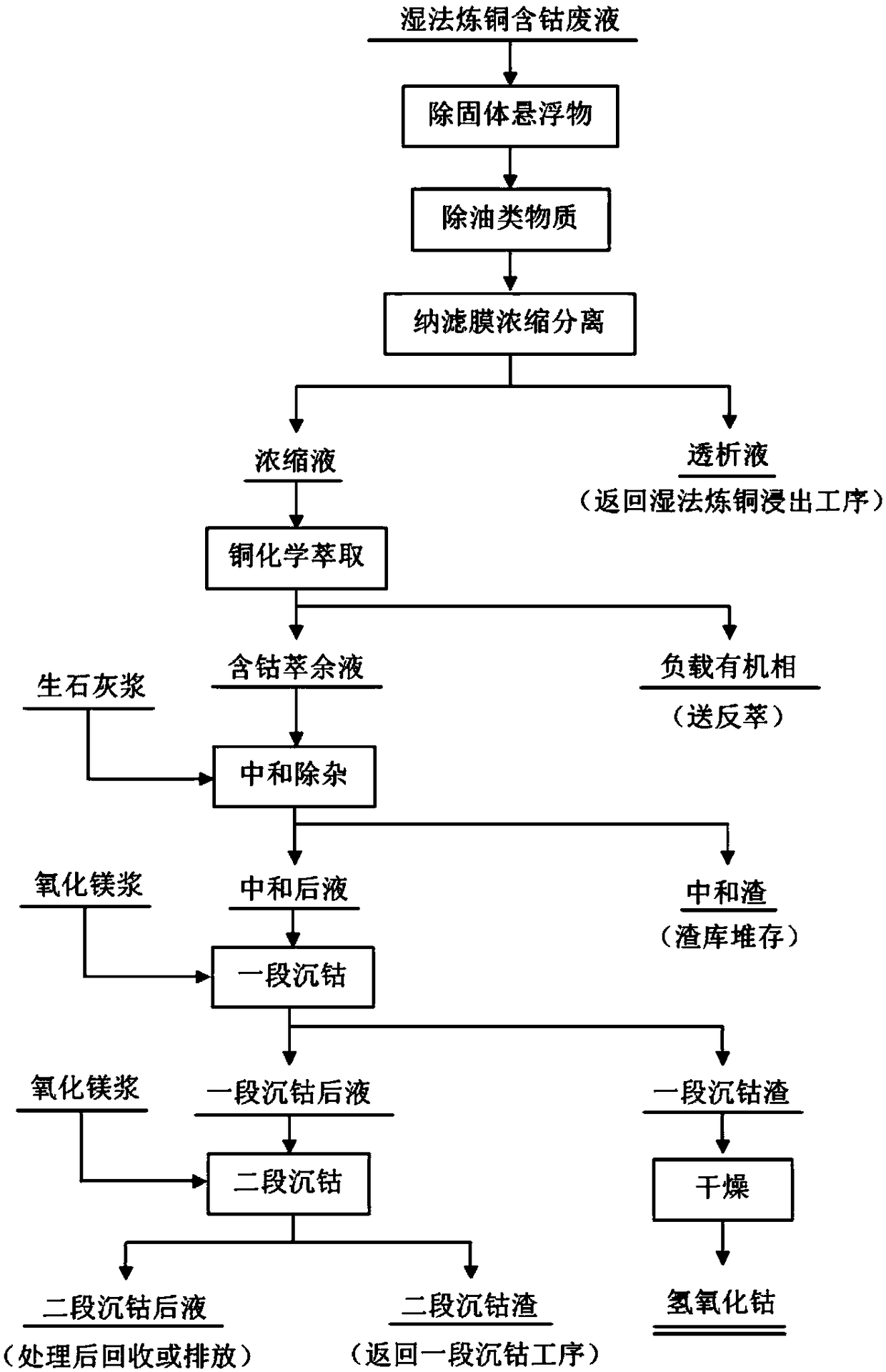

Method used

Image

Examples

Embodiment 1

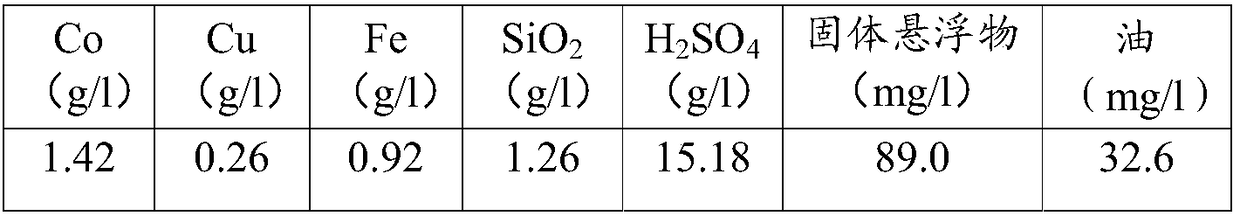

[0066] A copper-cobalt ore stirring leaching-extraction-electrowinning wet smelter in Congo (Kinshasa) with an annual output of 10,000 tons of cathode copper. The cobalt-containing waste liquid of copper hydro-smelting is the cobalt-containing raffinate after copper chemical extraction. Its main composition and their chemical composition are listed in Table 1.

[0067] Table 1 Main composition and chemical composition of cobalt-containing waste liquid of copper hydrosmelting in Example 1

[0068]

[0069] The processing step of embodiment 1 is specifically as follows:

[0070] Step 1a: Filter the cobalt-containing waste liquid of copper hydrosmelting with an activated carbon-quartz sand filter to obtain a cobalt-containing waste liquid with a suspended matter concentration of 4.2 mg / l.

[0071] Step 1b: Use an oil removal flotation machine to perform oil removal treatment on the filtrate to obtain a low-oil cobalt-containing waste liquid with an oil concentration of 3.8 mg...

Embodiment 2

[0082] A copper-cobalt ore with an annual output of 10,000 tons of cathode copper in the Congo (Kinshasa) is a stirring leaching-extraction-electrowinning wet smelter. The cobalt-containing waste liquid of the wet copper smelting is the tailings return water. Its main composition and chemical composition are shown in Table 4 shown.

[0083] Table 4 Main composition and chemical composition of cobalt-containing waste liquid of copper hydrosmelting in Example 2

[0084]

[0085] The processing steps of embodiment 2 are as follows:

[0086] Step 1a: Filter the cobalt-containing waste liquid of copper hydrosmelting with an activated carbon-quartz sand filter to obtain a cobalt-containing raffinate with a suspended matter concentration of 4.0 mg / l.

[0087] Step 1b: Use an oil removal flotation machine to perform oil removal treatment on the filtrate to obtain a low-oil cobalt-containing waste liquid with an oil concentration of 3.6 mg / l.

[0088] Step 2: Use a nanofiltration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com