Titanium bolt surface ceramization method based on in-situ growth

An in-situ growth and ceramicization technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of titanium bolt failure, corrosion failure of other parts, etc., to improve bearing capacity, resistance and wear resistance. Damage performance, good film bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

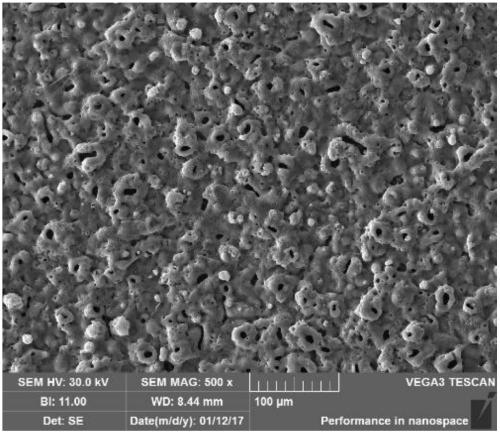

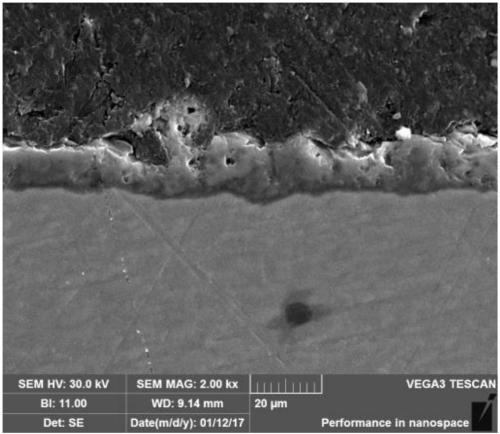

Image

Examples

Embodiment 1

[0042] Step 1. Surface pretreatment of titanium bolts of M8 (thread length 180mm) of TC4:

[0043] First, degrease and degrease the surface of the M8 titanium bolts of TC4, and then rinse them with deionized water; then, place the M8 titanium bolts of TC4 in a mixed electrolysis solution containing perchloric acid and glacial acetic acid at room temperature. Electrolytic polishing was carried out in a SORENSEN type electrolytic polishing machine with electrolytic solution. The electrolytic solution was a mixed solution of 50mL perchloric acid and 950mL glacial acetic acid. It was polished at a DC voltage of 55V for 30s, then rinsed with deionized water, and dried and stored with a hair dryer to obtain Pretreated titanium bolts;

[0044] Step 2. configuration pH is the electrolytic solution of the mixed acid system of 7, wherein comprises the sodium silicate of mass volume fraction 15%, the sodium aluminate of 10%, the sodium hexametaphosphate of 7%, the lemon of 5% in the elec...

Embodiment 2

[0048] Step 1. Surface pretreatment of titanium bolts of M8 (thread length 180mm) of TC4:

[0049] First, degrease and degrease the surface of the M8 titanium bolts of TC4, and then rinse them with deionized water; then, place the M8 titanium bolts of TC4 in a mixed electrolysis solution containing perchloric acid and glacial acetic acid at room temperature. Electrolytic polishing was carried out in a SORENSEN type electrolytic polishing machine with electrolytic solution. The electrolytic solution was a mixed solution of 50mL perchloric acid and 950mL glacial acetic acid. It was polished at a DC voltage of 55V for 30s, then rinsed with deionized water, and dried and stored with a hair dryer to obtain Pretreated titanium bolts;

[0050] Step 2. configuration pH is the electrolytic solution of the mixed acid system of 8.5, wherein comprises the sodium silicate of mass volume fraction 15%, the sodium aluminate of 10%, the sodium hexametaphosphate of 7%, the lemon of 5% in the el...

Embodiment 3

[0054] Step 1. Surface pretreatment of titanium bolts of M8 (thread length 180mm) of TC4:

[0055] First, degrease and degrease the surface of the M8 titanium bolts of TC4, and then rinse them with deionized water; then, place the M8 titanium bolts of TC4 in a mixed electrolysis solution containing perchloric acid and glacial acetic acid at room temperature. Electrolytic polishing was carried out in a SORENSEN type electrolytic polishing machine with electrolytic solution. The electrolytic solution was a mixed solution of 50mL perchloric acid and 950mL glacial acetic acid. It was polished at a DC voltage of 55V for 30s, then rinsed with deionized water, and dried and stored with a hair dryer to obtain Pretreated titanium bolts;

[0056] Step 2. configuration pH is the electrolytic solution of the mixed acid system of 9, wherein comprises the sodium silicate of mass volume fraction 15%, the sodium aluminate of 10%, the sodium hexametaphosphate of 7%, the lemon of 5% in the elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com