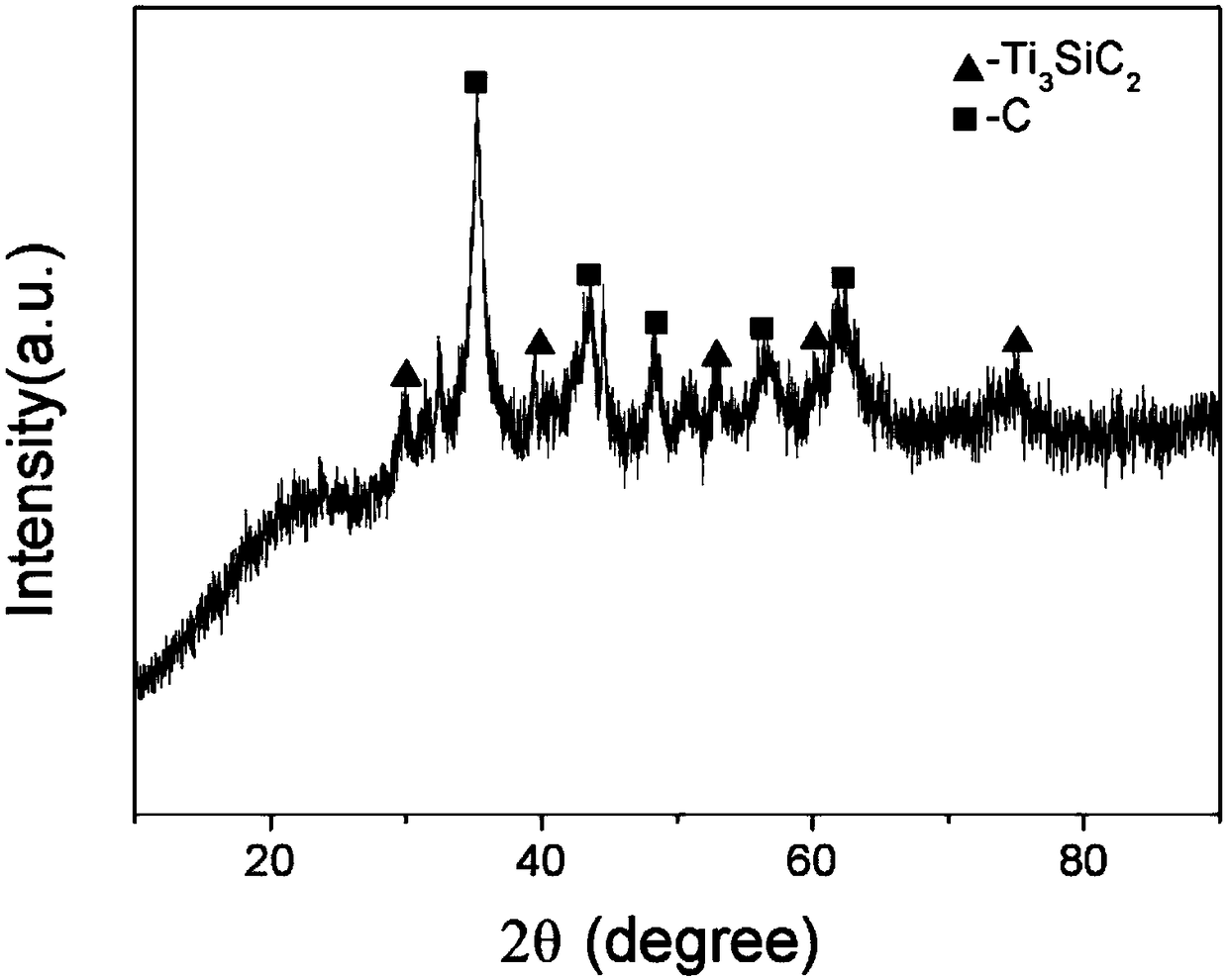

Titanium-silicon-carbon composite supercapacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, applied in hybrid capacitor electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve the adverse effects of electrochemical performance improvement, poor conductivity of oxides, poor electron transport capabilities, etc. problems, to achieve the effect of improving electrochemical performance, improving electrical conductivity, and excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of a titanium-silicon-carbon-carbon composite supercapacitor electrode material, comprising the steps of:

[0040] (1) Disperse 1.2g of titanium-silicon carbon powder in a mixture of 10mL of ethanol and acetic acid, 8mL of ethanol and 2mL of acetic acid in the mixture of ethanol and acetic acid, and then add 0.8g of polyvinylpyrrolidone (average molecular weight 130,000) to prepare Spinning precursor solution, electrospinning the precursor solution, pouring the precursor solution into a 20mL ordinary syringe during electrospinning, and electrostatically spinning under the conditions of voltage 16KV, humidity 45%rh and feeding rate 1.5mL / h Spinning to obtain raw silk;

[0041] (2) Carry out pre-oxidation to the raw silk in step (1): during pre-oxidation, the heating rate is 1° C. / min, and the temperature is kept at 250° C. for 2 hours;

[0042] (3) Carbonize the pre-oxidized raw silk in step (2): the heating rate during carbonization is 2°C / min, the...

Embodiment 2

[0044] A preparation method of a titanium-silicon-carbon-carbon composite supercapacitor electrode material, comprising the steps of:

[0045] (1) Disperse 0.6g of titanium-silicon carbon powder in a mixture of 10mL of ethanol and acetic acid, 8mL of ethanol and 2mL of acetic acid in the mixture of ethanol and acetic acid, and then add 0.8g of polyvinylpyrrolidone (average molecular weight 130000) to prepare Spinning precursor solution, electrospinning the precursor solution, pouring the precursor solution into a 20mL ordinary syringe during electrospinning, and electrostatically spinning under the conditions of voltage 16KV, humidity 45%rh and feeding rate 1.5mL / h Spinning to obtain raw silk;

[0046] (2) Carry out pre-oxidation to the raw silk in step (1): during pre-oxidation, the heating rate is 1° C. / min, and the temperature is kept at 250° C. for 2 hours;

[0047] (3) Carbonize the pre-oxidized raw silk in step (2): the heating rate during carbonization is 2°C / min, the ...

Embodiment 3

[0049] A preparation method of a titanium-silicon-carbon-carbon composite supercapacitor electrode material, comprising the steps of:

[0050] (1) Disperse 0.1g of titanium-silicon carbon powder in a mixture of 10mL of ethanol and acetic acid, 8mL of ethanol and 2mL of acetic acid in the mixture of ethanol and acetic acid, and then add 0.8g of polyvinylpyrrolidone (average molecular weight 130,000) to prepare Spinning precursor solution, electrospinning the precursor solution, pouring the precursor solution into a 20mL ordinary syringe during electrospinning, and electrostatically spinning under the conditions of voltage 16KV, humidity 45%rh and feeding rate 1.5mL / h Spinning to obtain raw silk;

[0051] (2) Carry out pre-oxidation to the raw silk in step (1): during pre-oxidation, the heating rate is 1° C. / min, and the temperature is kept at 250° C. for 2 hours;

[0052] (3) Carbonize the pre-oxidized raw silk in step (2): the heating rate during carbonization is 2°C / min, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com