A high-performance lithium-sulfur battery cathode material and a preparation method thereof

A lithium-sulfur battery and cathode material technology, which is applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc. Effects of redox processes, improved conductivity and reaction kinetics, high yield and industrial viability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

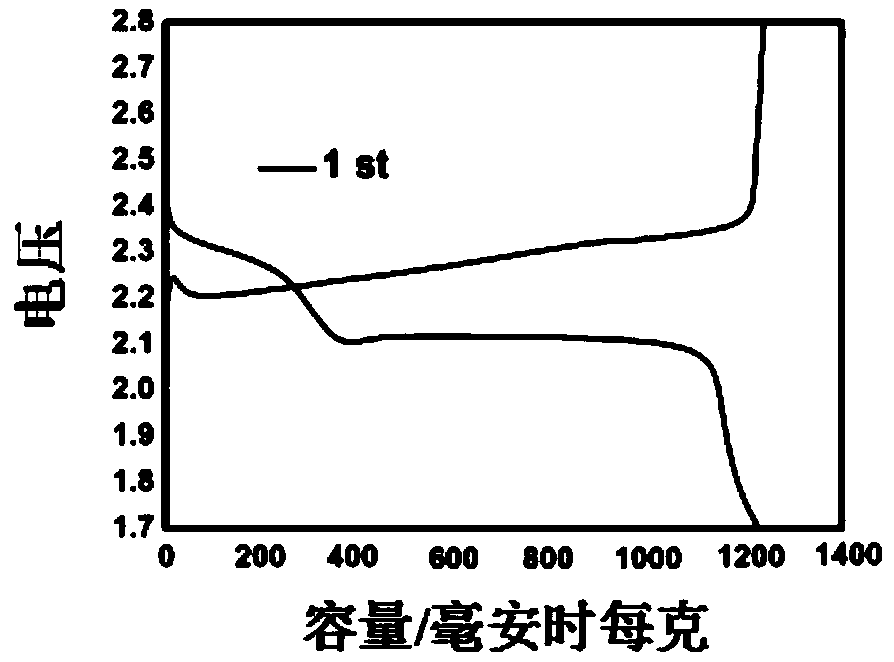

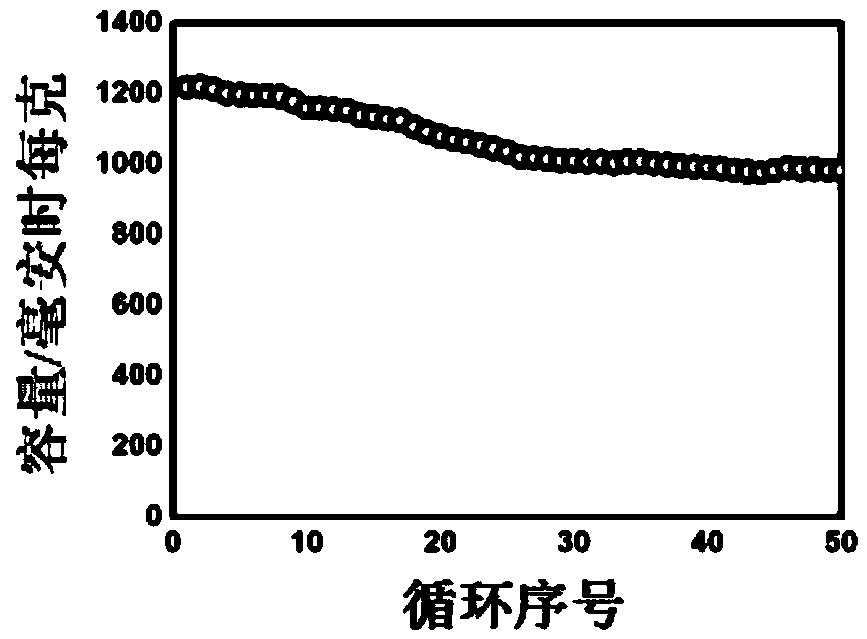

[0026] The high-performance lithium-sulfur battery cathode material is a porous flower-like CoP / C@S composite material.

[0027] The preparation method of the high-performance lithium-sulfur battery cathode material comprises the following steps:

[0028] (1) Preparation of flower-like cobalt chloride bismethanol nanosheet precursor:

[0029] 0.5~1gCoCl 2 ·6H 2 O was dissolved in a mixture of 30mL methanol and 10mL N,N-dimethylformamide to form a transparent solution; then, under continuous stirring, 5mmoL urea was added to the transparent solution to form a homogeneous system; then the obtained homogeneous system was transferred Put it into a 50mL polytetrafluoroethylene-lined stainless steel autoclave, seal it and keep it heated at 150°C for 12h, then cool to room temperature; after centrifugal precipitation, wash the powdery precipitate with distilled water and ethanol; finally wash the powdery precipitate Dry in an oven at 60°C for 6 hours;

[0030] (2) Preparation of ...

Embodiment 2

[0038] The preparation method of the high-performance lithium-sulfur battery cathode material comprises the following steps:

[0039] (1) Preparation of flower-like cobalt chloride bismethanol nanosheet precursor:

[0040] 1gCoCl 2 ·6H 2 O was dissolved in a mixture of 30mL methanol and 10mL N,N-dimethylformamide to form a transparent solution; then, under continuous stirring, 10mmoL urea was added to the transparent solution to form a homogeneous system; then the obtained homogeneous system was transferred Put it into a 50mL polytetrafluoroethylene-lined stainless steel autoclave, seal it and keep it heated at 150°C for 12h, then cool to room temperature; after centrifugal precipitation, wash the powdery precipitate with distilled water and ethanol; finally wash the powdery precipitate Dry in an oven at 60°C for 6 hours;

[0041] (2) Preparation of porous flower-like CoP / C nanosheets:

[0042] Put 0.15g of the precursor obtained in step (1) and 3.0g of sodium hypophosphit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com