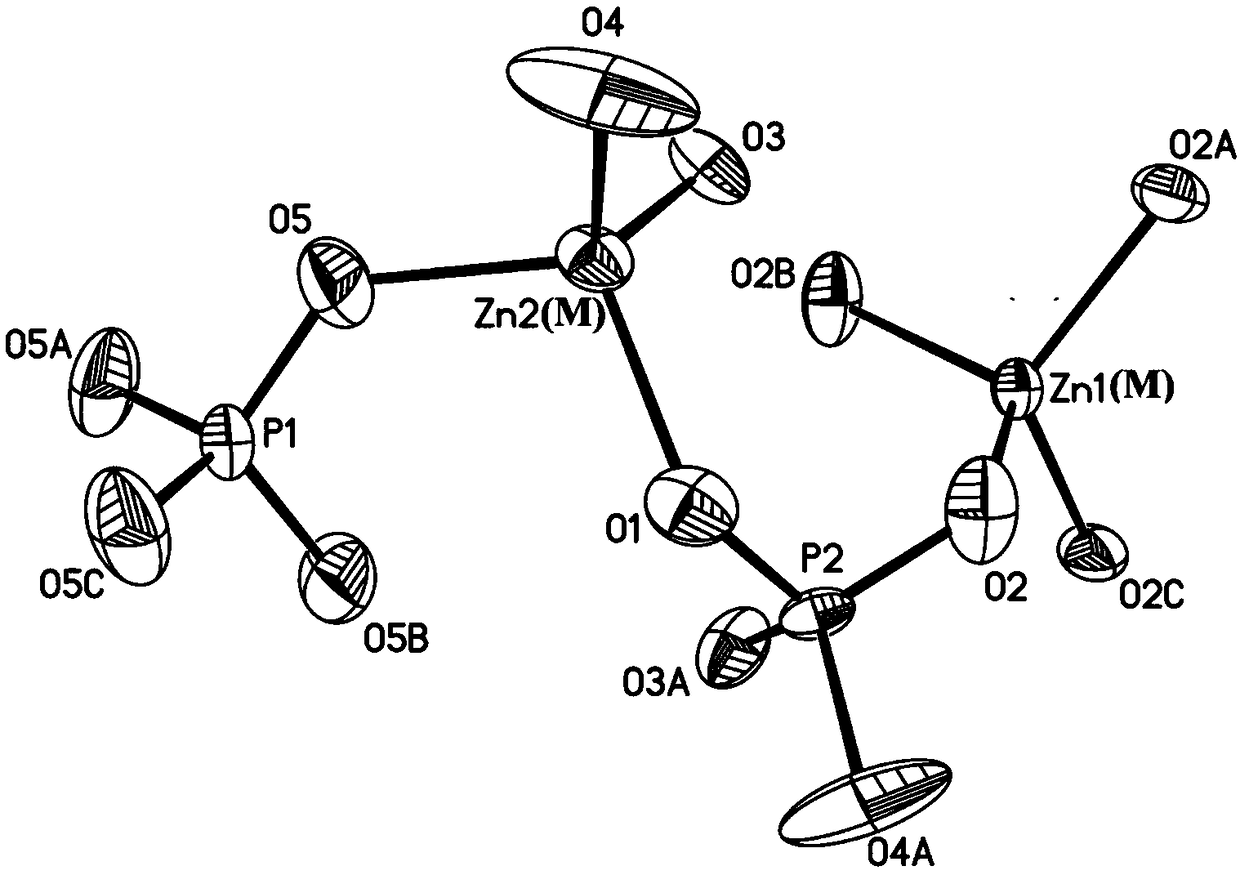

Metal-doped EDI-type zinc phosphate molecular sieve and synthesis method thereof

A technology of metal doping and synthesis method, which is applied in the direction of molecular sieve compounds, molecular sieves and base exchange phosphates, molecular sieve characteristic metal phosphates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

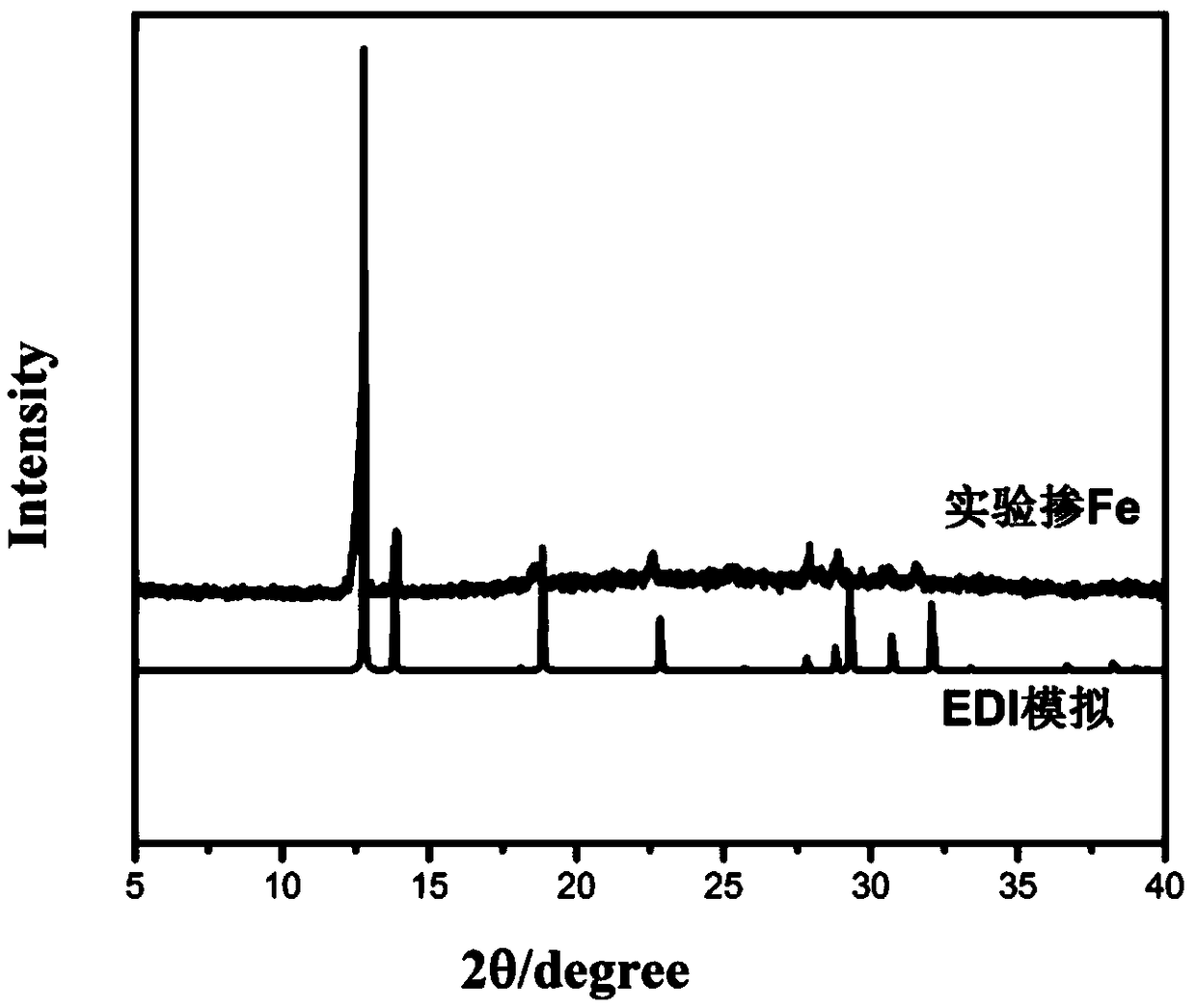

example 1

[0024] Mix zinc acetate and water, add ferric chloride, stir magnetically for 0.5h, add isobutanol, continue stirring for 0.5h, add phosphorous acid to the solution, continue stirring for 2h, add template agent 1,2-propylenediamine , and finally stirred for 2h to form an initial reaction mixture and obtain a sol; the molar ratio of the initial reaction mixture is Zn:Fe:H 3 PO 3 :1,2-propanediamine: H 2 O: isobutanol = 1.0: 1.0: 4.0-8.0: 6.0-10.0: 444.4-888.8: 60-100. The obtained sol was left to stand for 0.5h, put into a 25ml polytetrafluoroethylene reactor, and placed in a 180°C oven for crystallization for 3 days. After the reaction was completed, the reactor was taken out and cooled naturally at room temperature to remove the product. The solid product is separated, washed, and dried to obtain an iron-doped EDI molecular sieve. The obtained product is a dark green square crystal and does not contain other amorphous substances, such as Figure 3a shown.

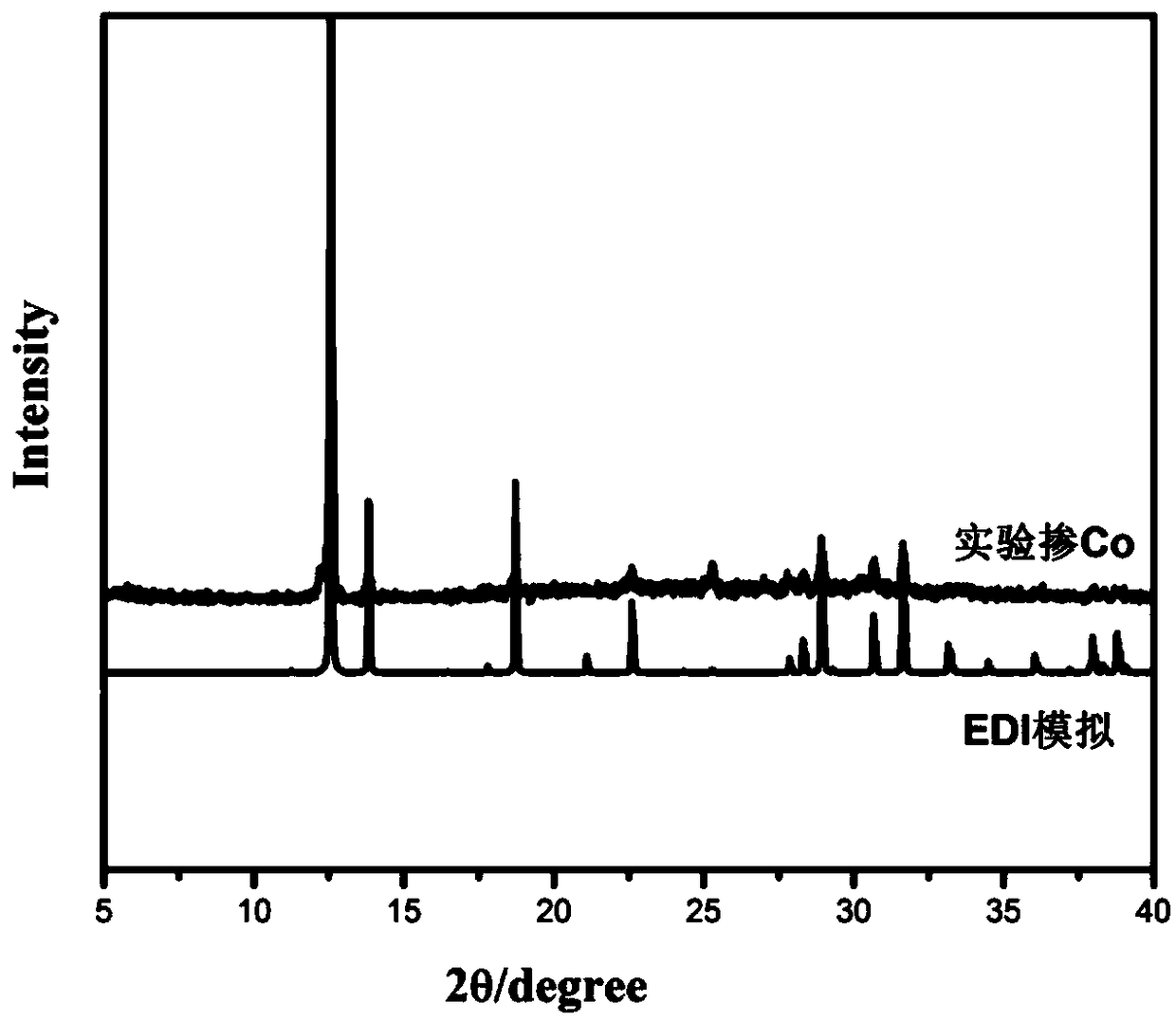

example 2

[0026] Mix zinc acetate and water, add cobalt acetate, stir magnetically for 0.5h, add isobutanol, continue stirring for 0.5h, add phosphorous acid to the solution, continue stirring for 3h, add template agent 1,2-propylenediamine, and finally Stir for 1h to form the initial reaction mixture and obtain a sol; the molar ratio of the initial reaction mixture is Zn:Co:H 3 PO 3 :1,2-propanediamine: H 2 O: isobutanol == 1.0: 1.0: 4.0-8.0: 6.0-10.0: 444.4-888.8: 60-100; the obtained sol was left to stand for 0.5h, put into a 25ml polytetrafluoroethylene reactor, and placed at 180 Crystallize in an oven at ℃ for 7 days. After the reaction is completed, take out the reaction vessel and let it cool naturally at room temperature to remove the product. The solid product is separated, washed and dried to obtain a cobalt-doped EDI molecular sieve. The obtained product is dark blue color cube crystals, such as Figure 3b shown.

example 3

[0028] Mix zinc chloride and water, add nickel chloride, stir magnetically for 0.5h, add isopropanol, continue stirring for 0.5h, add phosphorous acid to the solution, continue stirring for 1h, add template agent 1,2-propanedi Amine, and finally stirred for 1h to form the initial reaction mixture and obtain a sol; the molar ratio of the initial reaction mixture is Zn:Ni:H 3 PO 3 :1,2-propanediamine: H 2 O: Isopropanol = 1.0: 1.0: 4.0-8.0: 6.0-10.0: 444.4-888.8: 60-100; put the obtained sol for 0.5h, put it in a 25ml polytetrafluoroethylene reactor, and place it at 180°C Carry out crystallization in an oven for 5 days. After the reaction is completed, take out the reaction kettle and let it cool naturally at room temperature to remove the product. The solid product is separated, washed and dried to obtain a nickel-doped EDI molecular sieve. The obtained product is light green Cubic crystals with a relatively smooth surface, free of other amorphous phases such as Figure 3c s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com