Exchange bias nickel-base ferromagnetic/antiferromagnetic composite nano fiber and preparation method thereof

A technology of composite nanofibers and nanofibers, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems that do not involve ferromagnetic/antiferromagnetic composite nanofibers, and do not involve how to prepare iron. Magnetic/antiferromagnetic composite nanofibers, etc., to achieve the effects of low cost, increased coercivity, and simple equipment and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

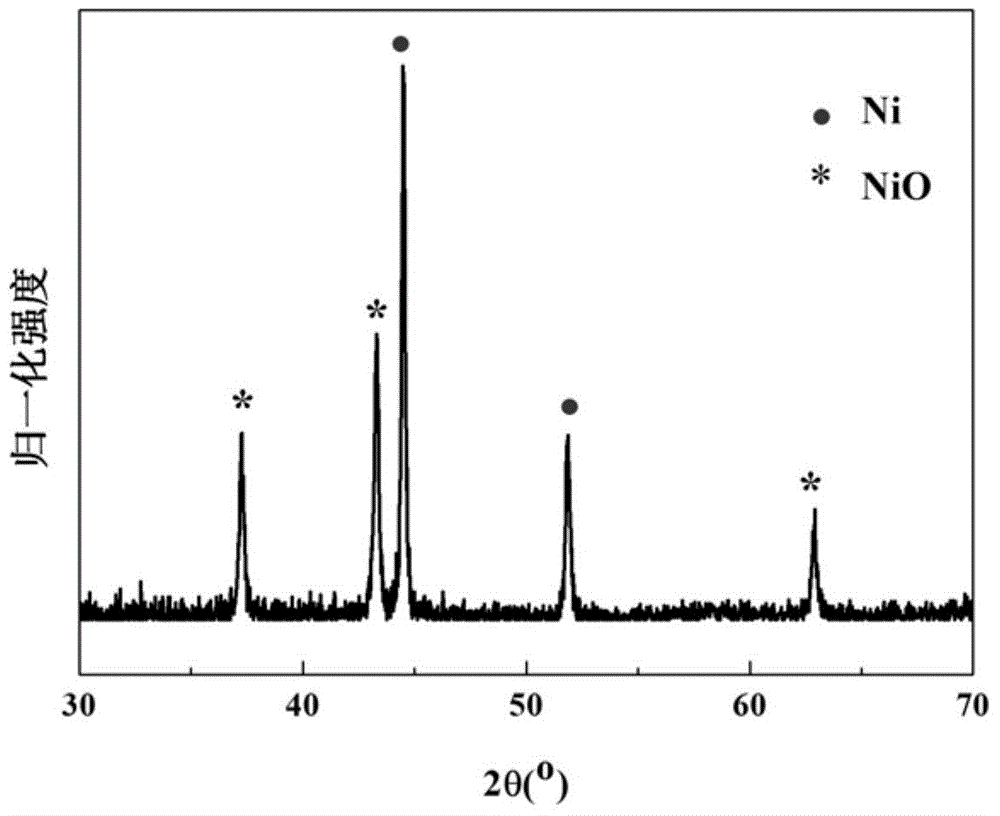

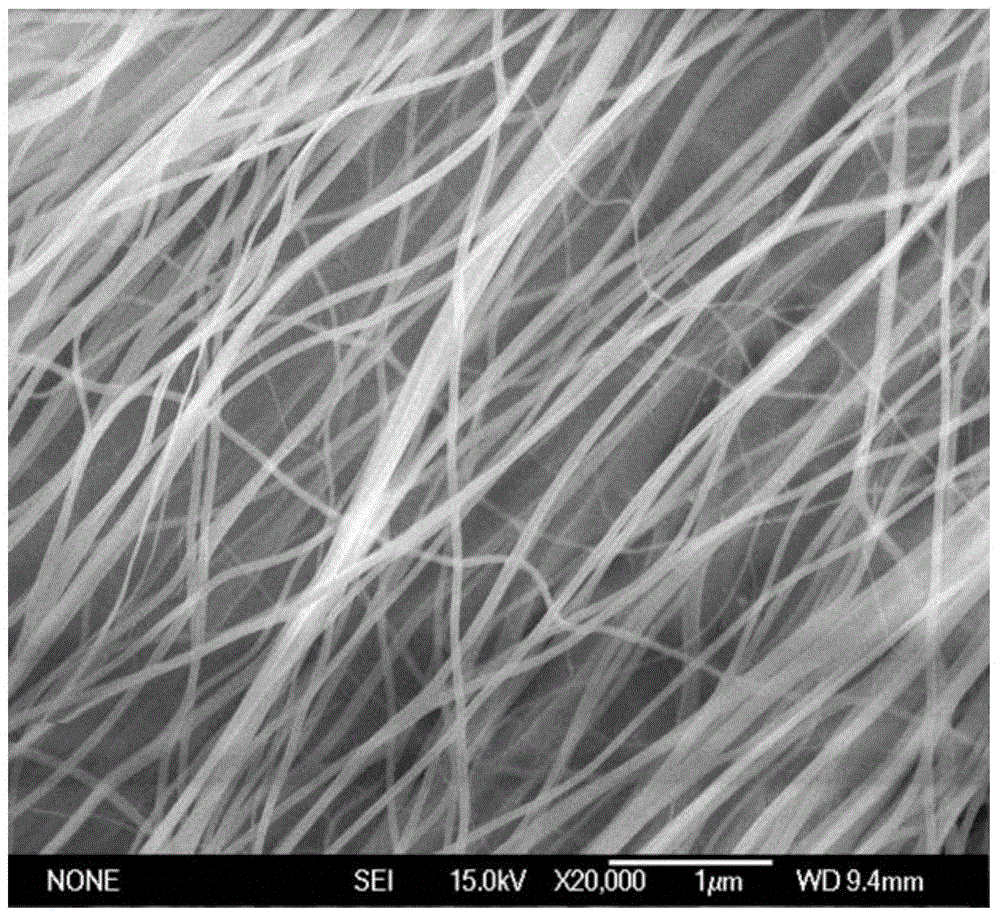

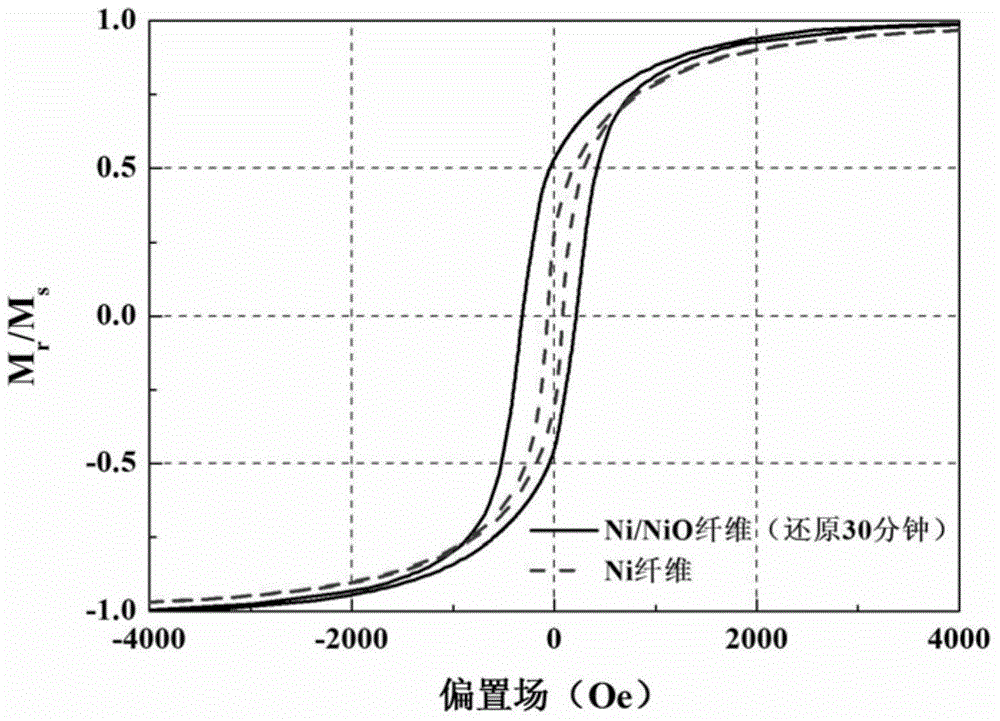

[0029] Example 1 (calcination at 550°C for 2h in air, reduction at 350°C for 30 minutes in a mixed atmosphere of hydrogen and argon):

[0030] Step 1: 0.80g nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O) Add 8.4g of N,N-dimethylformamide (DMF), stir the nickel salt for about 1 hour to completely dissolve the nickel salt, then add 0.80g of polyvinylpyrrolidone (PVP) with a molecular weight of 1,300,000 , the polymer is fully dissolved by magnetic stirring for about 12 hours, and then left to stand for 2 hours to finally form a uniform and stable sol-state precursor, wherein the concentration of PVP is 8wt%, and the concentration of nickel salt is 8wt%;

[0031] Step 2: Transfer the precursor solution to a 10ml plastic syringe, connect the syringe to a stainless steel needle with an outer diameter of 0.7mm and an inner diameter of 0.4mm with a polytetrafluoroethylene hose, the stainless steel needle is connected to the positive pole of the high voltage power supply, The spinning voltag...

Embodiment 2

[0036] Example 2 (calcination at 600°C for 2h in air, reduction at 350°C for 45 minutes in a mixed atmosphere of hydrogen and argon):

[0037] Step 1 is identical with embodiment 1 step 1;

[0038] Step 2 is identical with embodiment 1 step 2;

[0039] Step 3: Put the precursor fiber into the tube furnace, keep the air atmosphere, first raise the temperature from room temperature to 100°C at a heating rate of 3°C / min and keep it for 30 minutes, then raise the temperature to 600°C at the same heating rate and Keep warm for 2 hours, then cool down to room temperature naturally with the furnace body to obtain nickel oxide fibers;

[0040] Step 4: Place the nickel oxide fiber in a tube furnace, using a mixed atmosphere of hydrogen and argon with a hydrogen volume content of 5%, and ventilate for 30 minutes to ensure that the air in the tube is exhausted, and then at a heating rate of 3°C / min from The nickel oxide fiber is reduced by raising the temperature from room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com