Preparation method and application of vitamin E molecularly imprinted polymer

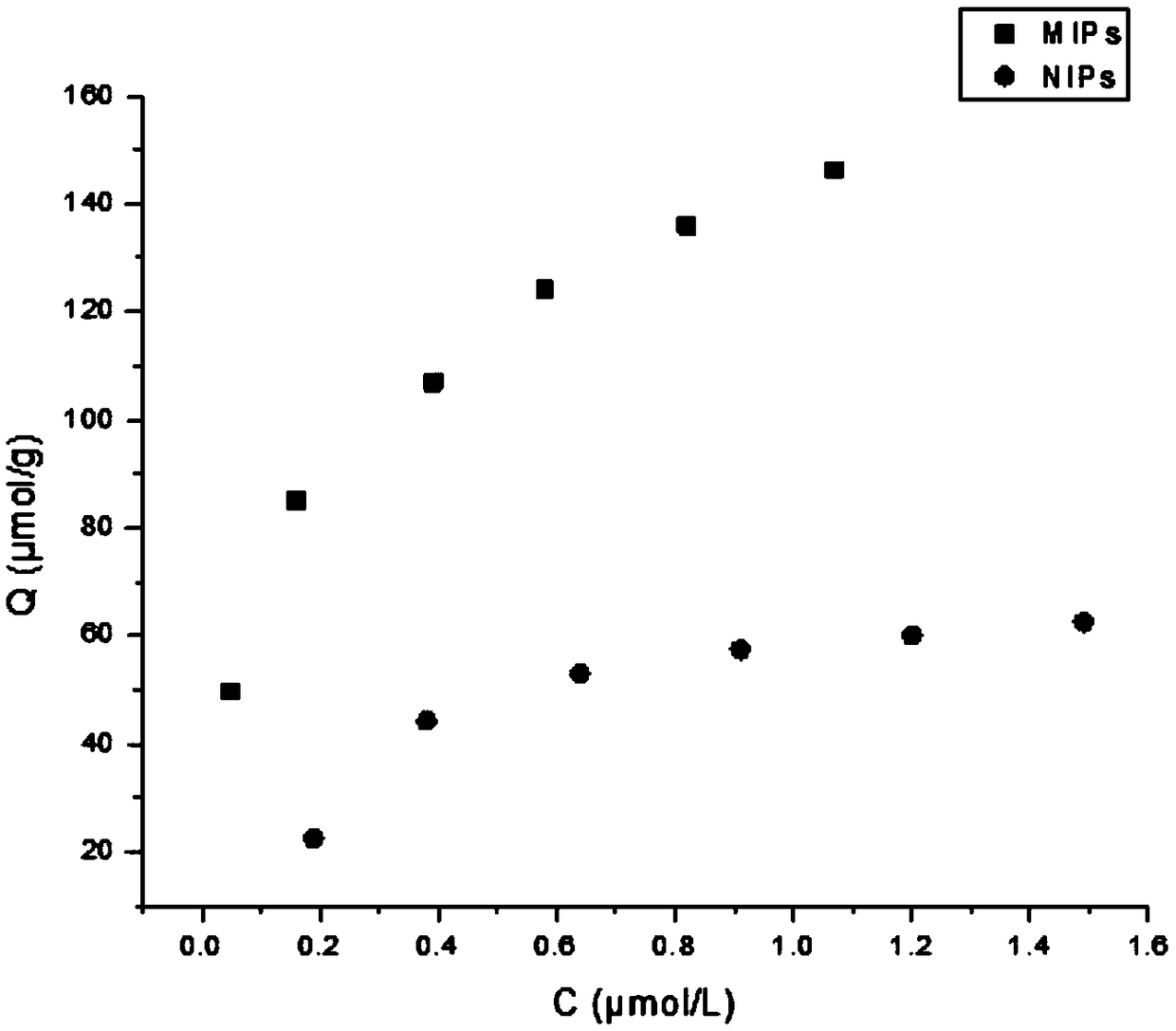

A molecular imprinting and polymer technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as the composition and structure of molecularly imprinted polymers that are not specifically disclosed, and achieve low preparation and use costs, high efficiency, and strong identification. The effect of capacity and adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Vitamin E and acrylamide were added to the acetone solution, wherein the amount of vitamin E was 0.11 g, the amount of acrylamide was 0.088 g, and the amount of acetone was 20 mL. After the above substances were mixed, they were sonicated for 20 minutes, and then transferred to a refrigerator at a constant temperature of 8°C for 10 hours.

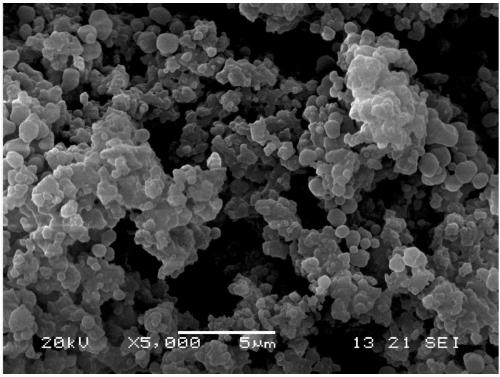

[0025] Get ethylene glycol dimethacrylate and azobisisobutyronitrile and join in the above-mentioned solution, wherein the consumption of ethylene glycol dimethacrylate is 0.96g, and the consumption of azobisisobutyronitrile is 0.03g, react The total volume concentration of the polymerization reaction monomer and the crosslinking agent in the liquid is 5%. After the addition was completed, the mixture was sonicated for 10 minutes, then the mixed solution was poured into the reaction device, and the temperature was raised to 68° C. for 20 hours under the condition of cutting off the air to obtain the molecularly imprinted polymer semi...

Embodiment 2

[0030] Vitamin E and acrylamide were added to the acetone solution, wherein the amount of vitamin E was 0.11 g, the amount of acrylamide was 0.088 g, and the amount of acetone was 30 mL. After the above substances were mixed, the mixture was sonicated for 10 minutes, and then transferred to a refrigerator at 10° C. for 12 hours.

[0031] Get ethylene glycol dimethacrylate and azobisisobutyronitrile and join in the above-mentioned solution, wherein the consumption of ethylene glycol dimethacrylate is 0.96g, and the consumption of azobisisobutyronitrile is 0.01g, react The total volume concentration of the polymerization reaction monomer and the crosslinking agent in the liquid is 3.5%. After the addition was completed, the mixture was sonicated for 10 minutes, then the mixed solution was poured into the reaction device, and the temperature was raised to 70° C. for 22 hours under the condition of cutting off the air to obtain a molecularly imprinted polymer semi-finished product...

Embodiment 3

[0035] Vitamin E and acrylamide were added to the acetone solution, wherein the amount of vitamin E was 0.11 g, the amount of acrylamide was 0.07 g, and the amount of acetone was 40 mL. After the above substances were mixed, the mixture was sonicated for 30 minutes, and then transferred to a refrigerator at 6° C. for 10 hours.

[0036] Get ethylene glycol dimethacrylate and azobisisobutyronitrile and join in the above-mentioned solution, wherein the consumption of ethylene glycol dimethacrylate is 1.25g, and the consumption of azobisisobutyronitrile is 0.02g, react The total volume concentration of the polymerization reaction monomer and the crosslinking agent in the liquid is 3%. After the addition was completed, the mixture was sonicated for 10 minutes, then the mixed solution was poured into the reaction device, and the temperature was raised to 65° C. for 20 hours under the condition of isolation from air to obtain a semi-finished product of molecularly imprinted polymer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com