Method for improving enzymolysis efficiency of bagasse through metal salt pretreatment strengthened by additives

A technology of enzymatic hydrolysis efficiency and pretreatment, applied in the direction of fermentation, etc., can solve the problems of long enzymatic hydrolysis time, increase the cost of glucose production, etc., and achieve the effect of improving enzymatic hydrolysis efficiency and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

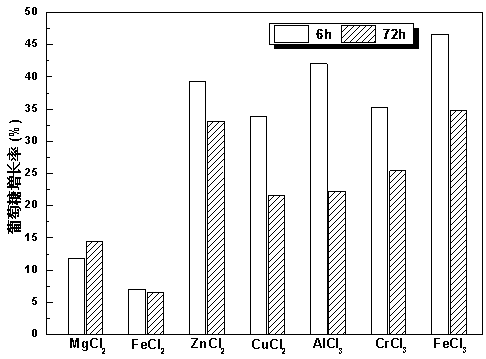

[0027] Weigh 50 grams of absolute dry bagasse raw material and place it in a closed reactor equipped with a thermocouple, add 500 milliliters of 0.025mol / L MgCl 2 Aqueous solution and 7.5 grams of Tween 80, start stirring, heat up to 160°C quickly and start timing, wait for the reaction time to reach 10 minutes, stop heating, and immediately use condensed water to reduce the reaction to room temperature, and use vacuum filtration method The pretreatment residue is separated off.

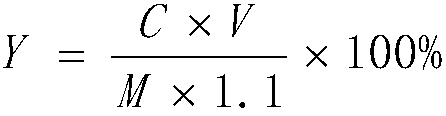

[0028] Take 5 grams (on an absolute dry basis) of the pretreatment residue, add 100 FPU of cellulase (Seli II) and 250 mL of acetic acid-sodium acetate buffer solution with pH=4.8 for enzymatic hydrolysis. During the enzymolysis process, the temperature was controlled at 50° C., and the rotation speed was 150 rpm. After 6 hours and 72 hours of enzymatic hydrolysis, 1mL samples were taken out and inactivated for 10min. The glucose concentration in the enzymolysis liquid was measured by high performan...

Embodiment 2

[0030] Weigh 50 grams of absolute dry bagasse raw material and place it in a closed reactor equipped with a thermocouple, add 500 milliliters of 0.025mol / LFeCl 2 Aqueous solution and 7.5 grams of Tween 80, start stirring, heat up to 160°C quickly and start timing, wait for the reaction time to reach 10 minutes, stop heating, and immediately use condensed water to reduce the reaction to room temperature, and use vacuum filtration method The pretreatment residue is separated off.

[0031] Take 5 grams (on an absolute dry basis) of the pretreatment residue, add 100 FPU of cellulase (Seli II) and 250 mL of acetic acid-sodium acetate buffer solution with pH=4.8 for enzymatic hydrolysis. During the enzymolysis process, the temperature was controlled at 50° C., and the rotation speed was 150 rpm. After 6 hours and 72 hours of enzymatic hydrolysis, 1mL samples were taken out and inactivated for 10min. The glucose concentration in the enzymolysis liquid was measured by high performanc...

Embodiment 3

[0033] Weigh 50 grams of absolute dry bagasse raw material and place it in a closed reactor equipped with a thermocouple, add 500 milliliters of 0.025mol / LZnCl 2 Aqueous solution and 7.5 grams of Tween 80, start stirring, heat up to 160°C quickly and start timing, wait for the reaction time to reach 10 minutes, stop heating, and immediately use condensed water to reduce the reaction to room temperature, and use vacuum filtration method The pretreatment residue is separated off.

[0034] Take 5 g (on an absolute dry basis) of the pretreatment residue, add 100 FPU of cellulase (Seli II) and 250 mL of acetic acid-sodium acetate buffer solution with pH=4.8 for enzymatic hydrolysis. During the enzymolysis process, the temperature was controlled at 50° C., and the rotation speed was 150 rpm. After 6 hours and 72 hours of enzymatic hydrolysis, 1mL samples were taken out and inactivated for 10min. The glucose concentration in the enzymolysis solution was measured by high performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com