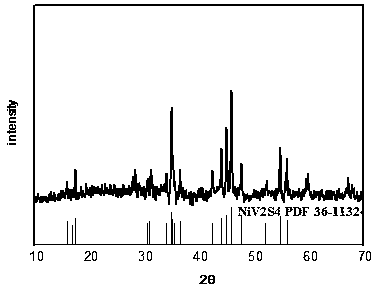

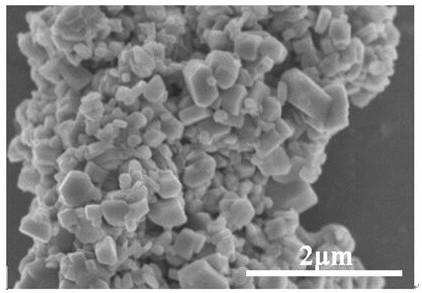

NiV2S4 electrocatalyst and preparation method thereof

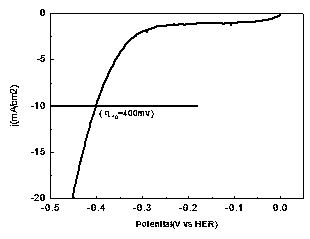

An electrocatalyst and mixture technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve problems such as no electrocatalytic hydrogen production research, and achieve cheap synthetic raw materials, low production costs, and high controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Put 200mg of thiocyanic acid, 66mg of nickel nitrate hexahydrate and 107mg of vanadium trichloride in a mortar for grinding, so that the raw materials in the mortar are evenly mixed, put the resulting mixture into a porcelain boat, and place the porcelain boat Place in a tube-type atmosphere furnace, and place two furnace plugs at each end of the tube.

[0021] Step 2: Inject inert gas into the tube, and then carry out 8 times of pumping and replenishing air, even if the air inside is exhausted, no gas will be replenished after the last pumping, and the air pressure in the tube is controlled to be -1~0MPa; when the air pressure is -1~0MPa Under normal circumstances, raise the temperature to 800°C at a rate of 10°C / min, and keep it warm for 3 hours; after the end of the heat preservation, open the air valve immediately, let the inert gas flow in at 700~800sccm, and discharge the sulfur vapor generated during the heat preservation process. Ensure that cooling is p...

Embodiment 2

[0024] Step 1: Put 400.8mg of thiocyanic acid, 290mg of nickel nitrate hexahydrate and 54mg of vanadium trichloride in a mortar for grinding, so that the raw materials in the mortar are evenly mixed, put the resulting mixture into a porcelain boat, and place the porcelain The boat is placed in a tube-type atmosphere furnace, and there are two furnace plugs at each end of the tube.

[0025] Step 2: Inject an inert gas into the tube, and then carry out 5 times of pumping to replenish the air, exhaust the air inside, and do not replenish the gas after the last pumping, and control the air pressure in the tube to -1~0MPa; when the air pressure is -1~0MPa Under normal circumstances, raise the temperature to 500°C at a rate of 10°C / min, and keep it warm for 3 hours; after the end of the heat preservation, open the air valve immediately, let the inert gas flow in at 700~800sccm, and discharge the sulfur vapor generated during the heat preservation process. Ensure that cooling is perf...

Embodiment 3

[0028] Step 1: Put 400.8mg of thiourea, 131mg of nickel nitrate hexahydrate and 118mg of vanadium acetylacetonate in a mortar for grinding, so that the raw materials in the mortar are evenly mixed, put the resulting mixture into a porcelain boat, and place the porcelain boat in the tube type atmosphere furnace, and two furnace plugs on each side of the tube ends.

[0029] Step 2: Inject inert gas into the tube, and then carry out 8 times of pumping and replenishing air, even if the air inside is exhausted, no gas will be replenished after the last pumping, and the air pressure in the tube is controlled to be -1~0MPa; when the air pressure is -1~0MPa Under normal circumstances, raise the temperature to 700°C at a rate of 5°C / min, and keep it warm for 3 hours; after the end of the heat preservation, immediately open the air valve, and let the inert gas flow in at 500~700sccm to discharge the sulfur vapor generated during the heat preservation process. Ensure that cooling is perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com