Ball-flower-like V-doped Ni3S2/NF self-supporting electrode material and preparation method thereof

A self-supporting electrode, flower ball technology, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problem of few reports, and achieve the effect of strong repeatability, easy operation and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Sonicate nickel foam by immersing it in acetone solution for 10 minutes, then transfer it to 2mol / L hydrochloric acid for ultrasonic cleaning for 10 minutes, and finally wash it alternately with ethanol and ultrapure water for 3 times, and then vacuum-dry it at 35°C for 10 hours;

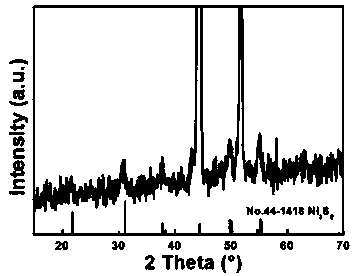

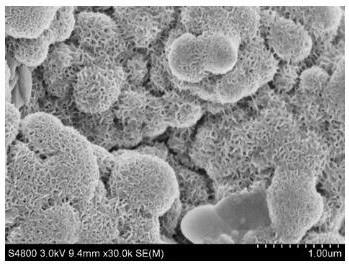

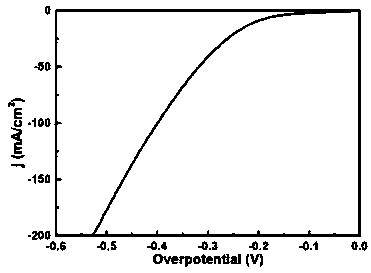

[0017] (2) Configure a precursor solution, which contains nickel chloride hexahydrate at a concentration of 0.05mol / L, vanadium chloride at a concentration of 0.0125mol / L, ammonium fluoride at a concentration of 0.05mol / L and 0.125) mol / L aqueous solution of urea, magnetically stirred at room temperature for 20 minutes to obtain a clear solution A. Transfer the clarified solution A and the conductive substrate treated in step (1) into a high-temperature and high-pressure hydrothermal kettle, and then react at 100°C for 18 hours, and the reaction filling ratio should be controlled at 40%. After the hydrothermal reaction was completed, the reactor was naturally cooled to room temperature, a...

Embodiment 2

[0020] (1) Soak nickel foam of 1cm x 5cm in acetone solution for 10 minutes, then transfer it to 2mol / L hydrochloric acid for 10 minutes, and finally rinse it with ethanol and ultrapure water for 3 times, and then clean it at 35°C. Vacuum drying for 10h;

[0021] (2) Configure a precursor solution, which contains nickel chloride hexahydrate at a concentration of 0.1mol / L, vanadium chloride at a concentration of 0.04mol / L, ammonium fluoride at a concentration of 0.05mol / L and Aqueous solution of 0.2mol / L urea, magnetically stirred at room temperature for 20min to obtain clear solution A. Transfer the clarified solution A and the conductive substrate treated in step (1) into a high-temperature and high-pressure hydrothermal kettle, and then react at 120°C for 14 hours, and the reaction filling ratio should be controlled at 40%. After the hydrothermal reaction was completed, the reactor was naturally cooled to room temperature, and then the conductive substrate cooled after the ...

Embodiment 3

[0024] (1) Sonicate 1cm x 5cm nickel foam in acetone solution for 5 minutes, then immerse foam nickel in 2mol / L hydrochloric acid for 5 minutes, and finally rinse with ethanol and ultrapure water for 3 times respectively. After vacuum drying for 10°C, the treated foamed nickel was obtained;

[0025] (2) Configure a precursor solution, which contains nickel chloride hexahydrate at a concentration of 0.1mol / L, vanadium chloride at a concentration of 0.05mol / L, ammonium fluoride at a concentration of 0.05mol / L and Aqueous solution of 0.2mol / L urea, magnetically stirred at room temperature for 20min to obtain clear solution A. Transfer the clarified solution A and the nickel foam treated in step (1) into a high-temperature and high-pressure hydrothermal kettle, and then react at 140°C for 10 hours, and the reaction filling ratio should be controlled at 30%. After the hydrothermal reaction was completed, the reactor was naturally cooled to room temperature, and then the conductive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com