Diamond-based multi-channel barrier regulation and control field-effect transistor and preparation method thereof

A diamond and field-controlling technology, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of sacrificing the maximum source-drain current, external transconductance, reducing surface channel carrier concentration and mobility, etc. Achieve the effect of ensuring current transport capability and strong carrier depletion capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

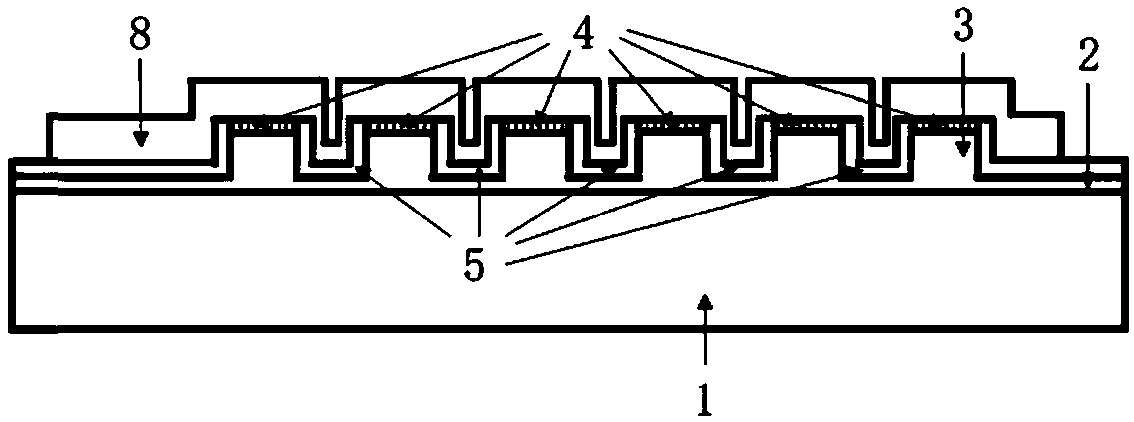

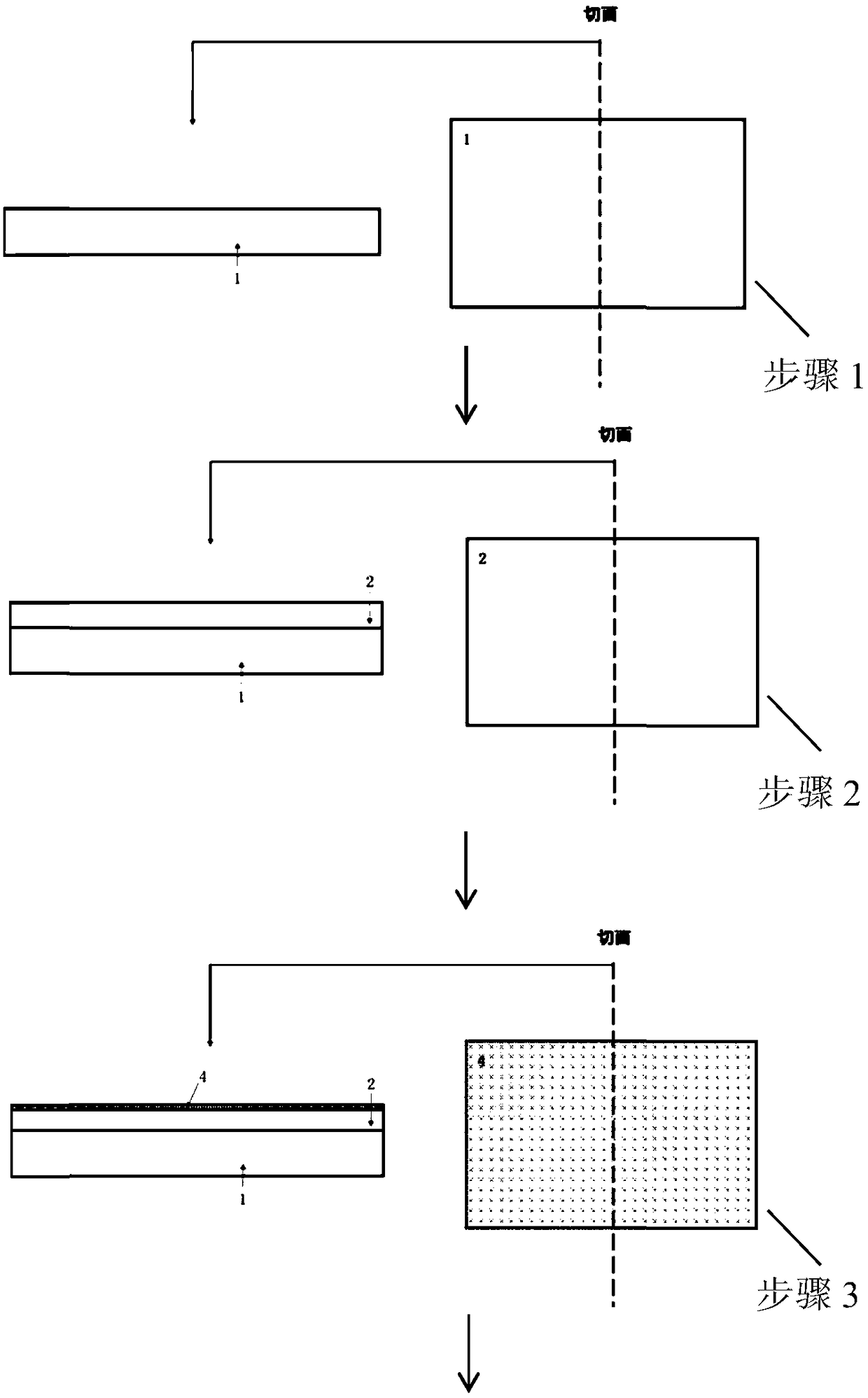

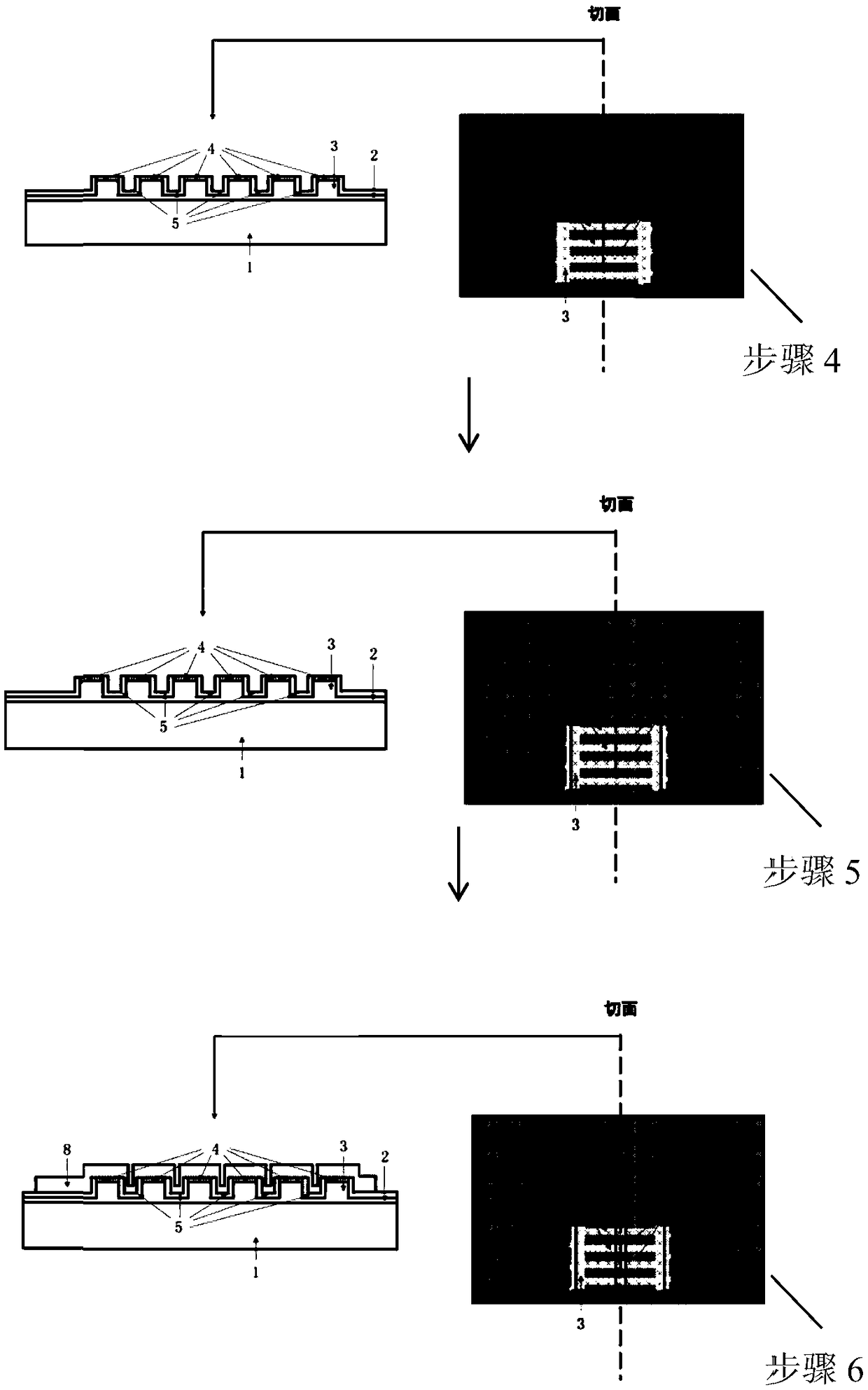

[0062] A method for preparing a diamond-based multi-channel barrier control field effect transistor, comprising the following steps:

[0063] 1) The diamond substrate 1 grown by high temperature and high pressure (HPHT) technology is cleaned successively by using the standard cleaning process for diamond substrates, followed by inorganic and organic cleaning, and blown dry with nitrogen gas for later use.

[0064] 2) Deposit a single crystal diamond film 2 on the cleaned diamond substrate using microwave plasma vapor chemical deposition (MPCVD), the plasma power is 1kW, the chamber pressure is 100Torr, and the total gas flow is 500sccm, and the obtained single crystal diamond The thickness of the film is 1μm, the resistivity is greater than 100MΩ·cm, the root mean square surface roughness is less than 0.5nm, and the half-peak width of the Raman curve is less than 2cm -1 , XRD rocking curve half width less than 30arcsec.

Embodiment 2

[0070] A method for preparing a diamond-based multi-channel barrier control field-effect transistor comprises the following steps:

[0071] 1) The diamond substrate 1 grown by CVD technology is successively cleaned inorganically and organically by using a standard cleaning process for diamond substrates, and blown dry with nitrogen gas for later use.

[0072] 2) Deposit a single crystal diamond film 2 on the cleaned diamond substrate using microwave plasma vapor chemical deposition (MPCVD), the plasma power is 1kW, the chamber pressure is 100Torr, and the total gas flow is 500sccm, and the obtained single crystal diamond The thickness of the film is 1μm, the resistivity is greater than 100MΩ·cm, the root mean square surface roughness is less than 0.5nm, and the half-peak width of the Raman curve is less than 2cm -1 , XRD rocking curve half width less than 30arcsec.

[0073] 3) Control the power of the microwave plasma so that the chamber temperature is 700° C., keep the hydro...

Embodiment 3

[0078] A method for preparing a diamond-based multi-channel barrier control field-effect transistor comprises the following steps:

[0079] 1) The diamond substrate 1 grown by CVD technology is successively cleaned inorganically and organically by using a standard cleaning process for diamond substrates, and blown dry with nitrogen gas for later use.

[0080] 2) Deposit a single crystal diamond film 2 on the cleaned diamond substrate using microwave plasma vapor chemical deposition (MPCVD), the plasma power is 1kW, the chamber pressure is 100Torr, and the total gas flow is 500sccm, and the obtained single crystal diamond The thickness of the film is 1μm, the resistivity is greater than 100MΩ·cm, the root mean square surface roughness is less than 0.5nm, and the half-peak width of the Raman curve is less than 2cm -1 , XRD rocking curve half width less than 30arcsec.

[0081] 3) Control the microwave plasma power so that the chamber temperature is 900° C., keep the hydrogen gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com