Lithium nitrogen oxygen battery with Fe nanoparticles and carbon composite as positive-electrode catalyst

A nanoparticle and composite material technology, which is used in fuel cell-type half cells and secondary battery-type half cells, battery electrodes, circuits, etc. The effect of electrical conductivity and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

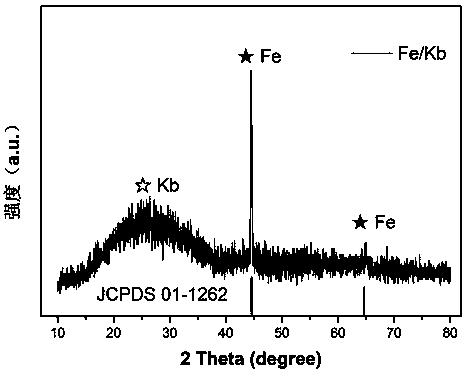

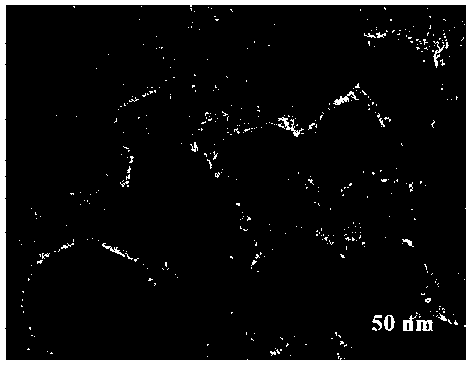

[0027] A lithium-nitrogen-oxygen battery using Fe / Kb as a catalyst, including iron nanoparticles highly dispersed on Ketjen black (EC-600JD Japan Lion King), this material is synthesized by hydrothermal method, the steps are: Ketjen black 50mg, Take 0.4g of ferric nitrate, 0.819g of urea, and 35mL of ethylene glycol, stir evenly at room temperature for 3h, sonicate for 1h, pour into the reaction kettle, and keep in an oven at 200°C for 4h; wash with ethanol until the supernatant is clear, take out the sample, Dry in an oven at 80°C for 24h; pre-calcine at 350°C for 3h in an argon atmosphere, then calcine at 750°C for 8h, and take it out of the tube furnace to prepare the Fe / Kb composite catalyst. The resulting composites were characterized as Figure 1-3 .

[0028] The catalyst is used to prepare the positive electrode sheet, and the steps are as follows: 1) Dissolve the Fe / Kb composite material and polyvinylidene fluoride (PVDF) in nitrogen methyl pyrrolidone (NMP) at a rati...

Embodiment 2

[0036] A new catalyst material for lithium-nitrogen-oxygen batteries, including iron nanoparticles highly dispersed on carbon nanotubes (Fe / CNTs). The material is synthesized by a hydrothermal method. The steps are: take 0.2 g of iron nitrate and 0.4 g of urea , 25 mg of carbon nanotubes (XFM40 Nanjing Pioneer Nano), dissolved in 35 ml of ethylene glycol, stirred at room temperature for 3 h, ultrasonicated for 1 h; poured into the reaction kettle, kept in an oven at 200 ° C for 4 h; washed with ethanol, until the supernatant The liquid is clarified, the sample is taken out, dried in an oven at 80°C for 24h, pre-calcined at 350°C for 3h in an argon atmosphere, then calcined at 750°C for 8h, and taken out from the tube furnace to obtain Fe / CNTs composite catalyst.

[0037] The catalyst is used to prepare the positive electrode sheet, and the steps are as follows: 1) Dissolve Fe / CNTs and PVDF in nitrogen methyl pyrrolidone (NMP) at a ratio of 90:10 by mass percentage, and mix th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com