A kind of compound fermented protein feed and preparation method thereof

A protein feed and compound fermentation technology, applied in biochemical equipment and methods, animal feed, animal feed, etc., can solve the problems of polluted environment, pomace becoming sour and smelly, and low protein content, so as to purify the environment and inhibit breeding , the effect of increasing protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

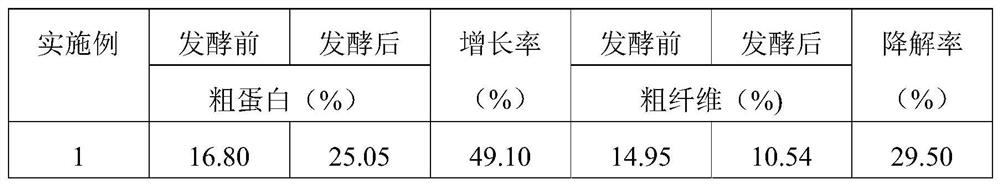

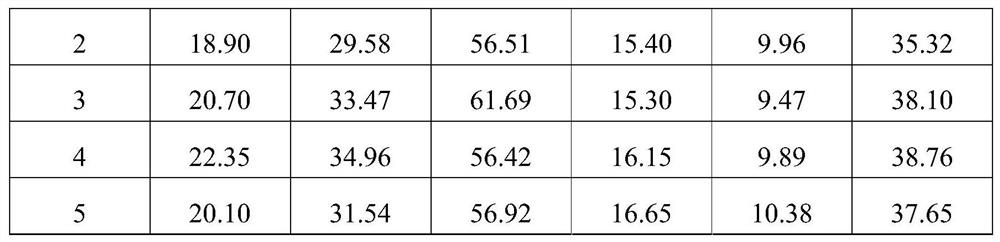

Examples

Embodiment 1

[0035] A preparation method for compound fermented protein feed, comprising the steps of:

[0036] (1) Preparation of strains

[0037] The preparation method of Candida utilis strain (ACCC20060) comprises the steps of: inserting Candida utilis into wort medium, initial pH 6.8~7.0, 26°C, 200r / min shaking culture for 24~ 36h, the number of viable bacteria reached 2.0×10 8 More than cfu / g; Candida utilis medium components are as follows: yeast extract 3g / L, malt extract 3g / L, peptone 5g / L, glucose 10g / L, water to 1L;

[0038] The preparation method of Bacillus subtilis liquid (ACCC11025) comprises the following steps: insert Bacillus subtilis into Bacillus subtilis culture medium, initial pH 7.0, 35°C, 200r / min shaking culture for 24-36h, the number of viable bacteria reaches 1.8× 10 8More than cfu / g; Bacillus subtilis medium components are as follows: glucose 25.0g / L, peptone 5.0g / L, beef extract 3.0g / L, yeast extract powder 1.0g / L, MgSO 4 ·7H 2 O 0.5g / L, MnSO 4 ·H 2 O 0....

Embodiment 2

[0045] A preparation method of compound protein fermented feed, comprising the steps of:

[0046] (1) Preparation of strains

[0047] Step is with embodiment 1

[0048] (2) Preparation of compound fermentation broth

[0049] Step is with embodiment 1

[0050] (3) Preparation of compound protein fermented feed

[0051] Fully mix 50 parts of bean dregs (moisture content 30-40%), 25 parts of apple pomace (moisture content 25-30%), 15 parts of corn flour and 10 parts of bran to prepare the mixed material to be fermented; ) with the compound fermentation bacteria liquid prepared in ) to inoculate the above-mentioned mixed material to be fermented according to the inoculum amount of 15% by weight, and add water to adjust the final moisture content of the material to 50%, fully mix and place it still for 1-2 days; then put the material Put it into a packaging bag with a one-way outlet valve device, seal it, and ferment it statically at 28-35°C for 3-5 days to make a compound ferm...

Embodiment 3

[0053] A preparation method of compound protein fermented feed, comprising the following steps:

[0054] (1) Preparation of strains

[0055] Step is with embodiment 1

[0056] (2) Preparation of compound fermentation broth

[0057] Step is with embodiment 1

[0058] (3) Preparation of compound protein fermented feed

[0059] Fully mix 60 parts of bean dregs (moisture content 30-40%), 20 parts of apple pomace (moisture content 25-30%), 10 parts of corn flour and 10 parts of bran to prepare the mixed material to be fermented; ) to inoculate the above-mentioned mixed material to be fermented with the inoculum amount of 10% by weight, and add water to adjust the final moisture content of the material to 45%, mix well and leave it still for 1 to 2 days; then put the material into Put it into a packaging bag with a one-way outlet valve device, seal it, and ferment it statically at 28-35°C for 3-5 days to make a compound fermented protein feed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com