A kind of compound fermented feed for dairy cows, its preparation method and application

A compound fermentation, dairy cow technology, applied in the direction of bacteria, applications, animal feed, etc. used in food preparation, can solve the problems affecting the quantity and quality of milk production, the health threat of dairy cows, and the unreasonable proportion of feed ingredients, and improve the Micro-ecological environment, the effect of increasing milk production and increasing absorptive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

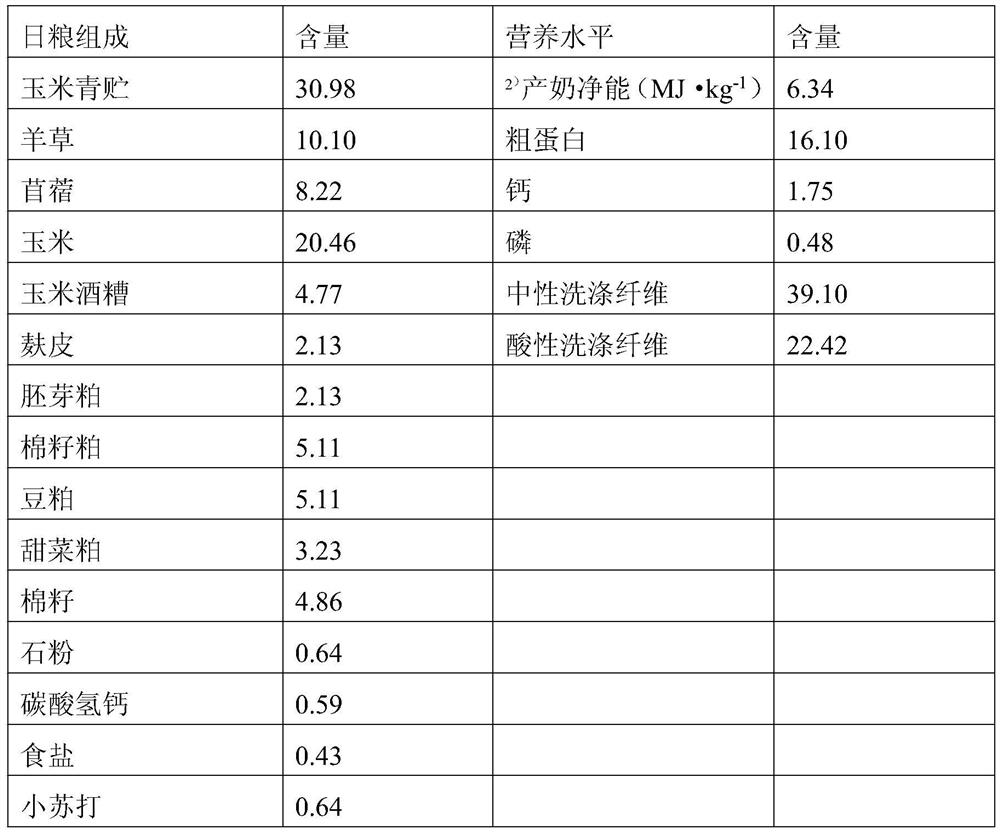

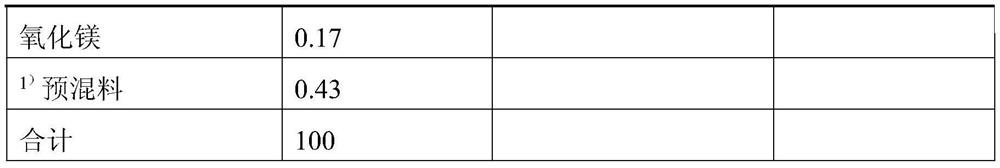

Examples

Embodiment 1

[0043] A preparation method of fermented algae powder, the steps are as follows:

[0044] (1) Dry and pulverize macroalgae, pass through a 40-mesh sieve, sterilize by high-pressure steam at 121°C for 15 minutes, cool to room temperature, and set aside;

[0045] (2) Centrifuge the culture fluid of Chlorella and Chrysophylla respectively to obtain the algae mud of Chlorella and Chrysophylla; mix the algae mud of Chlorella and Chrysophylla according to the weight ratio of 1:1, and add 10% sterilized macroalgae powder, mixed evenly to obtain algae mixture;

[0046] (3) Add 1.8% compound microbial bacterial agent to the algae mixture, ferment for 24-36 hours at 32°C;

[0047] (4) After the fermentation is completed, add mannitol with a total weight of 5% to the fermented product, mix evenly, and vacuum freeze-dry to form a powder to obtain fermented algae powder.

[0048] The composite microbial bacterial agent is composed of Bacillus subtilis and Lactobacillus rhamnosus in a mas...

Embodiment 2

[0056] A preparation method of fermented peanut meal is:

[0057] (1) Mechanically pulverize the peanut meal, pass through a 20-mesh sieve, and sterilize by high-pressure steam at 121°C for 30 minutes. After the sterilization is completed, cool to room temperature;

[0058] (2) Adjust the moisture content of the sterilized peanut meal to 55-65%, inoculate the fermentation strains of 8% Aspergillus oryzae and 4% Aspergillus niger into the peanut meal, and after fully mixing, carry out solid-state fermentation at 28°C-32°C , after 36 hours of fermentation, and then 48 hours of fermentation at 32-35°C;

[0059] (3) Add 1 times the weight of deionized water to the material after the above-mentioned fermentation is completed, adjust pH 7.0, 40°C, enzymolysis 2h; adjust pH 4.5, 40°C, enzymolysis 4h; after enzymolysis, 100 ℃, treated for 10 minutes, cooled to room temperature, that is.

[0060] Activation of Aspergillus oryzae and Aspergillus niger and preparation of fermentation s...

Embodiment 3

[0065] A compound fermented feed for dairy cows, consisting of the following components in parts by weight:

[0066] 20 parts of rice husk, 46 parts of fermented peanut meal, 50 parts of ammoniated corn stalks, 10 parts of fermented algae powder, 2 parts of chitosan oligosaccharide, 2 parts of oyster powder, and 2 parts of medical stone powder.

[0067] The preparation method of compound fermented feed for described cows, the steps are as follows:

[0068] (1) Weigh rice husks, fermented peanut meal, ammoniated corn stalks, and fermented algae powder according to the amount and mix them evenly. Adjust the water content to 65-70%. 32°C, stack for 5-6 hours;

[0069] (2) Add chitosan oligosaccharide, oyster powder, and medical stone powder to the mixture in 1), add it into a mixer, stir evenly, and discharge.

[0070] The preparation method of the ammoniated corn stalks is:

[0071] (1) remove sundries from corn stalks, cut them into small sections of 1-2 cm, soak them with w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com