Chemical leaching-electric repairing method for heavy metal contaminated soil

A technology for electric repair and polluted soil, applied in the restoration of polluted soil, etc., can solve the problems of insufficient separation effect of heavy metals, and achieve the effects of saving manpower and material resources, simple and convenient operation, and high removal rate of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

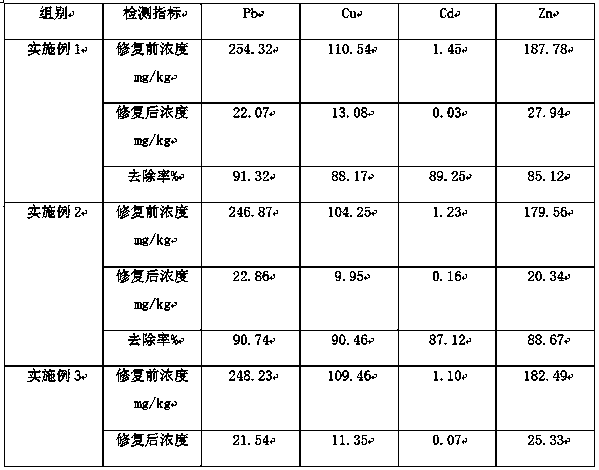

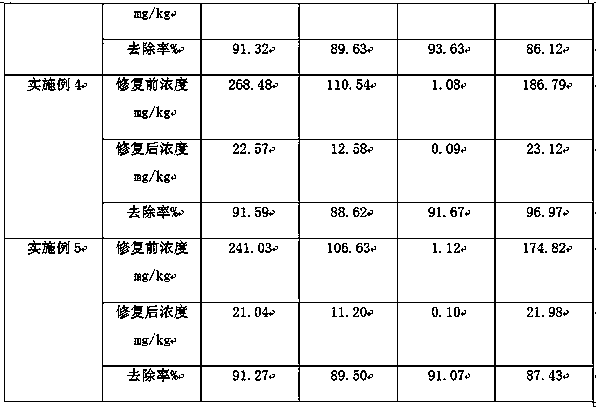

Examples

Embodiment 1

[0023] (1) Close the switchable partition of the electric repair device, and mix xylitol fatty acid ester, 0.1mol / L citric acid, and hydrolyzed maleic anhydride at a mass ratio of 5:2:1 to prepare a rinse agent; The electrolytic tank in the restoration device is used to rinse the soil with a leaching agent, and the mass ratio of the leaching agent to the soil is 1:1;

[0024] (2) Add acetic acid-sodium acetate buffer solution with a pH of 2 to 5 in the anode chamber, add 0.15mol / L potassium nitrate solution in the cathode chamber, connect the direct current between the graphite anode and the graphite cathode, and recover heavy metal ions in the cathode chamber; turn on the electric repair The switchable partition of the device recovers the heavy metal filtrate in the collection tank. After electrolysis, the filtrate can be reused as a washing agent and recover heavy metals at the same time.

Embodiment 2

[0026] (1) Close the switchable partition of the electric repair device, and mix xylitol fatty acid ester, 0.3mol / L tartaric acid, and hydrolyzed maleic anhydride with a mass ratio of 4:2:1 to prepare a rinse agent; The soil is rinsed with a leaching agent in the electrolytic cell in the device, and the mass ratio of the leaching agent to the soil is 1.3:1;

[0027] (2) Add acetic acid-sodium acetate buffer solution with a pH of 2 to 5 in the anode chamber, add 1.3mol / L potassium nitrate solution in the cathode chamber, connect the direct current between the graphite anode and the graphite cathode, and recover heavy metal ions in the cathode chamber; turn on the electric repair The switchable partition of the device recovers the heavy metal filtrate in the collection tank. After electrolysis, the filtrate can be reused as a washing agent and recover heavy metals at the same time.

Embodiment 3

[0029] (1) Close the switchable partition of the electric repair device, and mix xylitol fatty acid ester, 0.4mol / L sodium gluconate, and hydrolyzed maleic anhydride at a mass ratio of 6:2:1 to prepare a leaching agent; In the electrolytic cell of the electric repair device, the soil is rinsed with a leaching agent, and the mass ratio of the leaching agent to the soil is 1.2:1;

[0030] (2) Add acetic acid-sodium acetate buffer solution with a pH of 2 to 5 in the anode chamber, add 0.08mol / L potassium nitrate solution in the cathode chamber, connect the direct current between the graphite anode and the graphite cathode, and recover heavy metal ions in the cathode chamber; turn on the electric repair The switchable partition of the device recovers the heavy metal filtrate in the collection tank. After electrolysis, the filtrate can be reused as a washing agent and recover heavy metals at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com