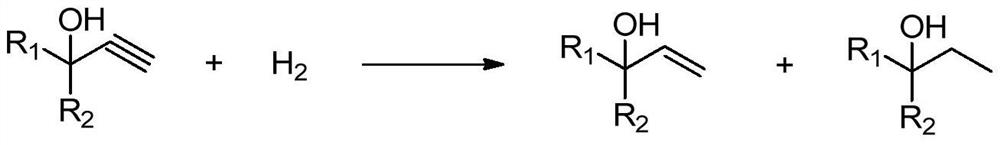

A kind of method for preparing enol through partial hydrogenation of acetylenic alcohol

A technology for hydrogen preparation and alkynol, applied in the field of production of VE main intermediates, can solve the problems of increased equipment investment, difficult separation, etc., and achieves the effect of no influence on quality and odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

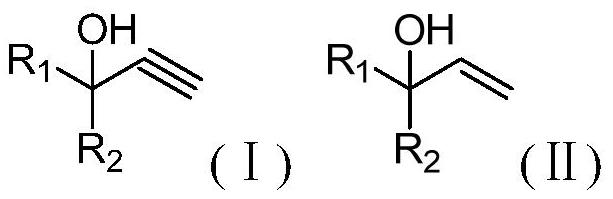

Method used

Image

Examples

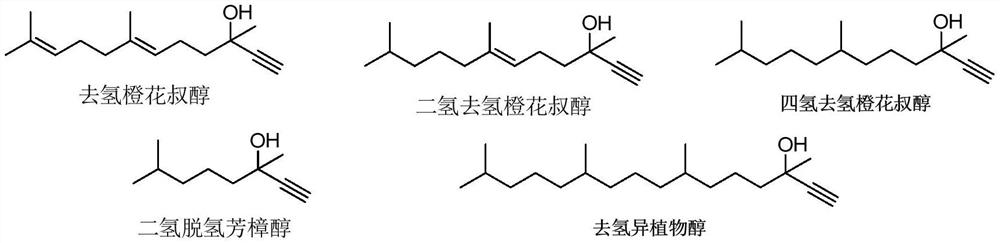

Embodiment 1

[0034] First, add 224.4 g of tetrahydro dehydronerolidol, 2 g of palladium-calcium carbonate catalyst, 1.0 g of acetone dimethyl acetal, and 250 g of heptane into the autoclave, seal the autoclave, and replace it with nitrogen for 3 times, then press it to 3.0 MPa with nitrogen After confirming that the autoclave is well sealed, evacuate the nitrogen, replace it with hydrogen containing 500ppm carbon monoxide for 6 times, turn on the stirring paddle, keep the hydrogen pressure at 0.1MPa, and keep the inner temperature of the reactor at 30°C for 3 hours. After the stirring was stopped and the air was vented, the reaction solution was analyzed by GC. The composition of the reaction solution was: 97.8% nerolidol, 1.4% tetrahydrodehydronerolidol, 0.6% dihydronerolidol, and 0.2% others. Filter the reaction liquid, add 0.5 g of pure water, and distill at 90°C to remove the solvent heptane and ketal, then raise the temperature to 160°C, and distill at 1KPa to obtain 224.3g of product ...

Embodiment 2

[0036] First, add 294.5g of dehydroisophytol, 1.5g of palladium-calcium carbonate catalyst, 2.0g of acetonide, and 250g of heptane into the autoclave, seal the autoclave, and replace the nitrogen gas three times, then press the nitrogen gas to 3.0MPa to confirm the autoclave After the sealing is good, the nitrogen is evacuated, replaced with hydrogen containing 1000ppm carbon monoxide for 6 times, the stirring paddle is turned on, the hydrogen pressure is kept at 0.15MPa, and the inner temperature of the reactor is kept at 30°C for 3 hours. After the stirring was stopped and the air was vented, the reaction solution was analyzed by GC. The composition of the reaction solution was: 97.2% isophytol, 1.6% dehydroisophytol, 0.5% dihydroisophytol, and 0.7% others. Filter the reaction liquid, add 0.5 g of pure water, and distill at 110°C to remove the solvent heptane and ketal, then raise the temperature to 160°C, and distill at 500 Pa to obtain 293.8 g of product liquid.

[0037] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com