Copper-based tandem catalytic electrode as well as preparation process and application thereof

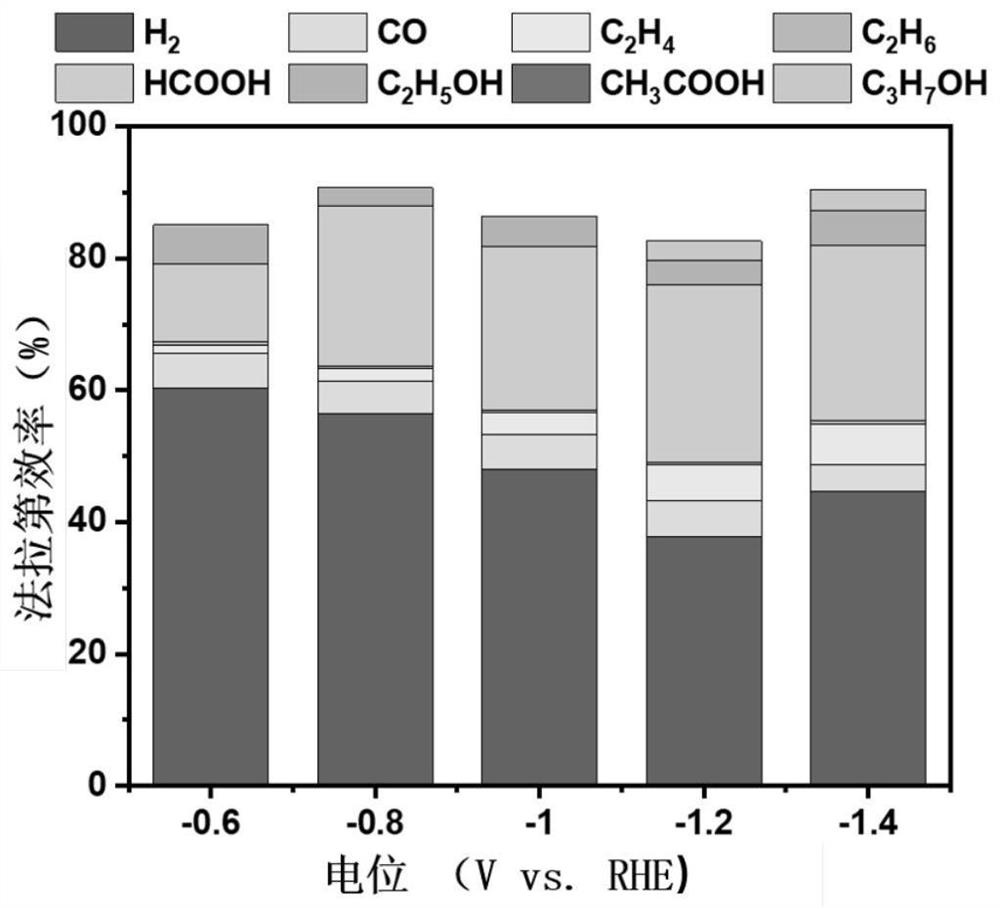

A catalytic electrode and preparation process technology, applied in the field of electrochemical catalysis, can solve the problems that hinder the application of industrial-level multi-carbon product production technology, poor selectivity of Cu catalyst, high reduction potential difference, etc., to achieve large-scale industrial application, The effect of improving catalytic activity and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

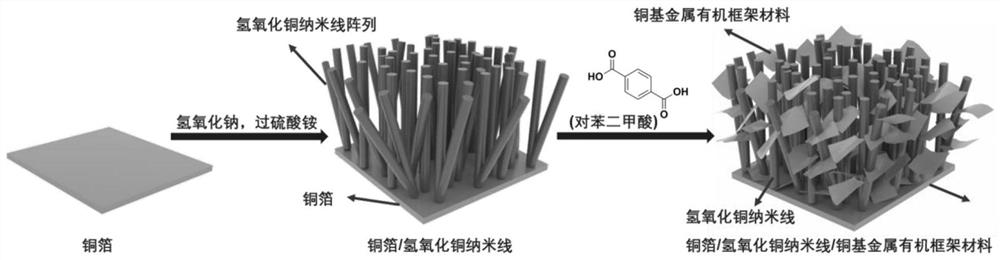

[0032] A preparation method of copper-based tandem catalyst, comprising the following steps:

[0033] (1) Electrochemical polishing of copper foil: Polish a commercial copper foil with a thickness of 50 μm. In this embodiment, the polishing solution is 0.5 mol / L sulfuric acid solution, and the polishing time is 30 minutes. Rinse the polished copper foil with deionized water and ethanol to remove the solution on the surface, and let it stand and dry at room temperature.

[0034] (2) Growth of copper hydroxide nanowire arrays: the polished copper foil is placed in a mixed solution of sodium hydroxide and ammonium persulfate, wherein the concentrations of sodium hydroxide and ammonium persulfate are 2.67mol / L and 0.13 mol / L, let stand for 5min, then rinse with deionized water and dry in air.

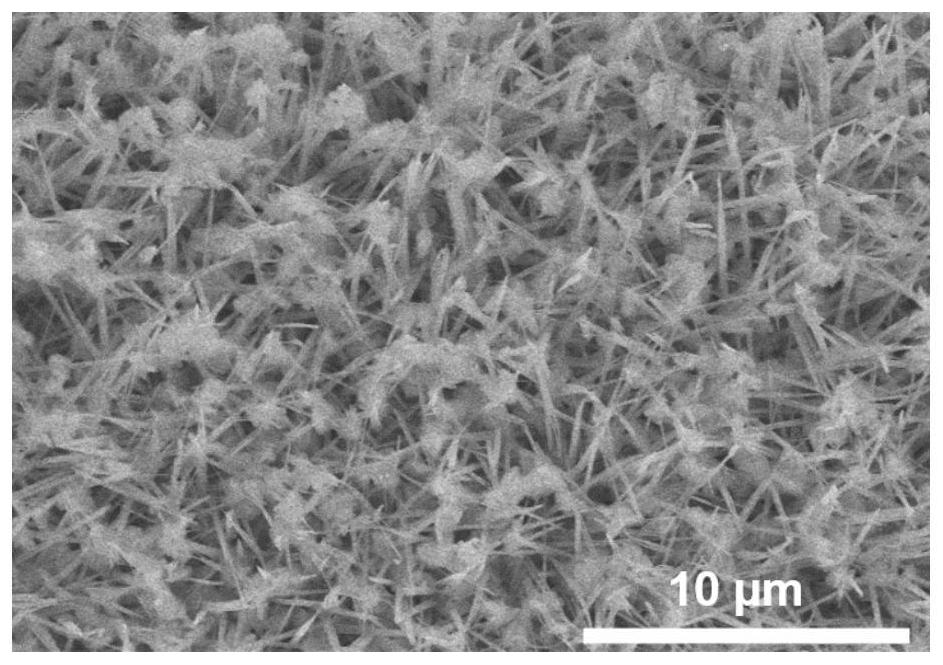

[0035] (3) Growth of Cu-MOF: The copper foil on which the copper hydroxide nanowire array was grown was placed in a 5 mmol / L terephthalic acid solution, the reaction temperature was 100° C...

Embodiment 2

[0037] A preparation method of copper-based tandem catalyst, comprising the following steps:

[0038] (1) Electrochemical polishing of copper foil: Polish a commercial copper foil with a thickness of 50 μm. In this embodiment, the polishing solution is 0.5 mol / L sulfuric acid solution, and the polishing time is 40 minutes. Rinse the polished copper foil with deionized water and ethanol to remove the solution on the surface, and let it stand and dry at room temperature.

[0039] (2) Growth of copper hydroxide nanowire arrays: the polished copper foil is placed in a mixed solution of sodium hydroxide and ammonium persulfate, wherein the concentrations of sodium hydroxide and ammonium persulfate are 2.97mol / L and 0.15 mol / L, let stand for 8min, then rinse with deionized water and dry in air.

[0040] (3) Growth of Cu-MOF: The copper foil on which the copper hydroxide nanowire array was grown was placed in a 7 mmol / L terephthalic acid solution, the reaction temperature was 80° C....

Embodiment 3

[0042] A preparation method of copper-based tandem catalyst, comprising the following steps:

[0043] (1) Electrochemical polishing of copper foil: Polish a commercial copper foil with a thickness of 50 μm. In this embodiment, the polishing solution is 0.5 mol / L sulfuric acid solution, and the polishing time is 50 minutes. Rinse the polished copper foil with deionized water and ethanol to remove the solution on the surface, and let it stand and dry at room temperature.

[0044] (2) Growth of copper hydroxide nanowire arrays: the polished copper foil is placed in a mixed solution of sodium hydroxide and ammonium persulfate, wherein the concentrations of sodium hydroxide and ammonium persulfate are 3.17mol / L and 0.18mol / L respectively. mol / L, stand for 10min, then rinse with deionized water, and dry in air.

[0045] (3) Growth of Cu-MOF: The copper foil on which the copper hydroxide nanowire array was grown was placed in a 10 mmol / L terephthalic acid solution, the reaction temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com