Composite phase VPO catalyst and preparation method and application thereof

A catalyst and composite phase technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, preparation of organic compounds, etc., to achieve high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

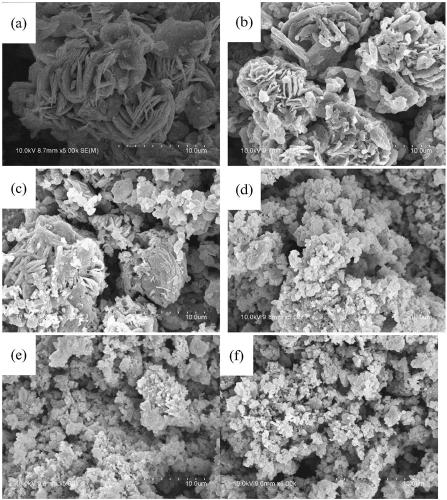

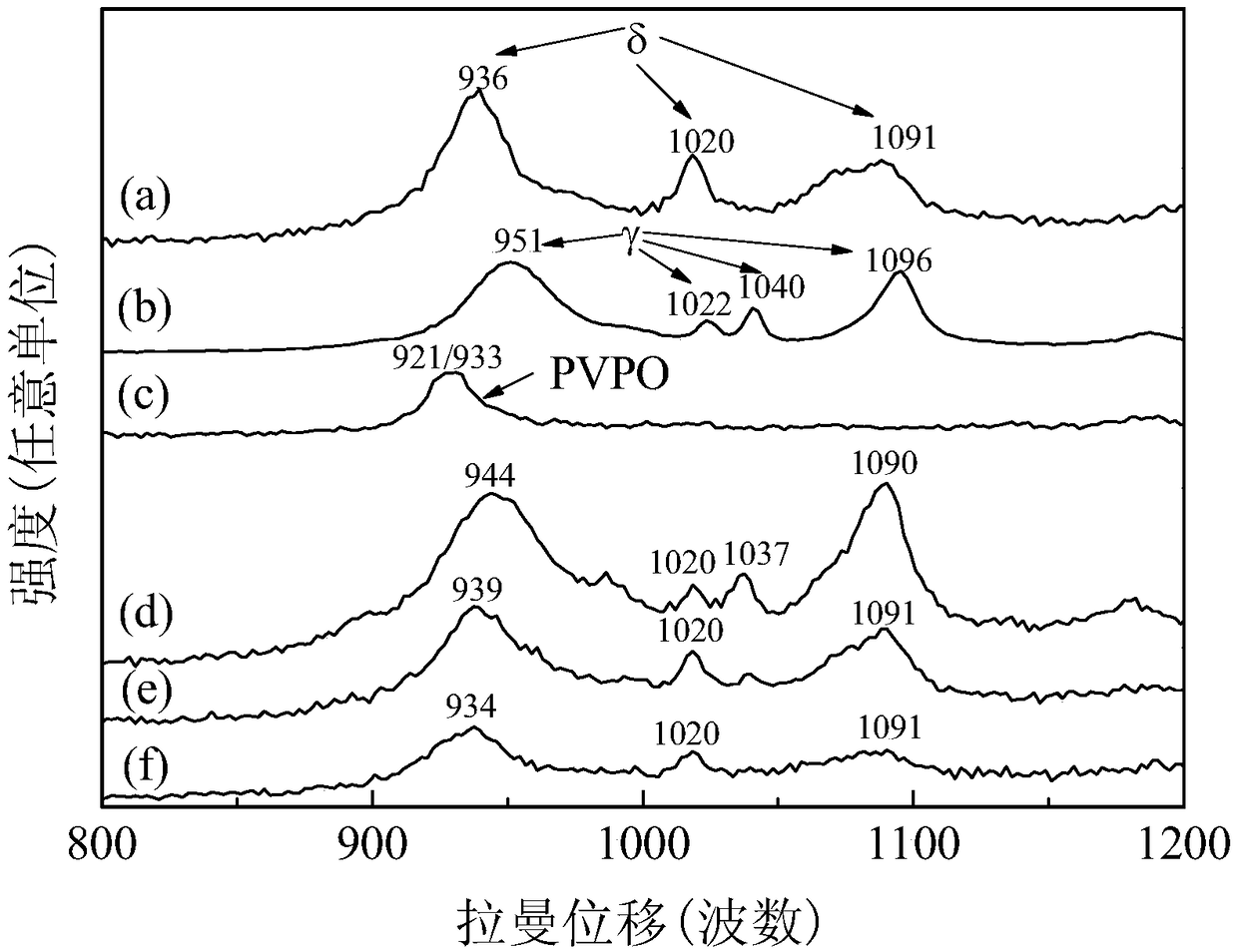

Embodiment 1

[0022]4.8g of vanadium pentoxide and 72ml of benzyl alcohol were refluxed at 140°C for 5 hours, and 2.1g of PEG6000 was added to the reaction medium. After 1 hour, 6.44g of concentrated phosphoric acid with a mass percent concentration of 85% was added and refluxed for 6 hours to obtain The dark blue suspension mixture was filtered, washed with acetone, and dried at 100°C for 24 hours to obtain a VPO precursor. The precursor is loaded into an inline activation tube with an internal diameter of 50mm, and is heated from room temperature to 400°C at a rate of 2°C / min in 1.5% n-butane / air flow (90ml / min), and kept for 15 hours to obtain ( VO) 2 P 2 o 7 ; The VPO precursor was heated from room temperature to 400°C at a rate of 2°C / min in an oxygen flow of 40ml / min and kept for 15 hours to obtain δ-VOPO 4 . Will (VO) 2 P 2 o 7 and δ-VOPO 4 According to the mass ratio of 3:1, it was mixed and ball milled on an omnidirectional ball mill for 12 hours to obtain a VPO catalyst ap...

Embodiment 2

[0025] 4.8g of vanadium pentoxide and 72ml of benzyl alcohol were refluxed at 140°C for 5 hours, and 2.1g of PEG6000 was added to the reaction medium. After 1 hour, 6.44g of concentrated phosphoric acid with a mass percent concentration of 85% was added and refluxed for 6 hours to obtain The dark blue suspension mixture was filtered, washed with acetone, and dried at 100°C for 24 hours to obtain a VPO precursor. The precursor is loaded into an inline activation tube with an internal diameter of 50mm, and is heated from room temperature to 400°C at a rate of 2°C / min in 1.5% n-butane / air flow (90ml / min), and kept for 15 hours to obtain ( VO) 2 P 2 o 7 ; The VPO precursor was heated from room temperature to 400°C at a rate of 2°C / min in an oxygen flow of 40ml / min and kept for 15 hours to obtain δ-VOPO 4 . Will (VO) 2 P 2 o 7 and δ-VOPO 4 According to the mass ratio of 1:3, it was mixed and ball milled on an omnidirectional ball mill for 12 hours to obtain a VPO catalyst u...

Embodiment 3

[0028] 4.8g of vanadium pentoxide and 72ml of benzyl alcohol were refluxed at 140°C for 5 hours, and 2.1g of PEG6000 was added to the reaction medium. After 1 hour, 6.44g of concentrated phosphoric acid with a mass percent concentration of 85% was added and refluxed for 6 hours to obtain The dark blue suspension mixture was filtered, washed with acetone, and dried at 100°C for 24 hours to obtain a VPO precursor. The precursor is loaded into an inline activation tube with an internal diameter of 50mm, and is heated from room temperature to 400°C at a rate of 2°C / min in 1.5% n-butane / air flow (90ml / min), and kept for 15 hours to obtain ( VO) 2 P 2 o 7 ; The VPO precursor was heated from room temperature to 400°C at a rate of 2°C / min in an oxygen flow of 40ml / min and kept for 15 hours to obtain δ-VOPO 4 . Will (VO) 2 P 2 o 7 and δ-VOPO 4 According to the mass ratio of 1:1, they were mixed and ball milled on an omnidirectional ball mill for 4 hours to obtain a VPO catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com