Method for preparing methyl methacrylate through aldol condensation of methyl propionate and formaldehyde

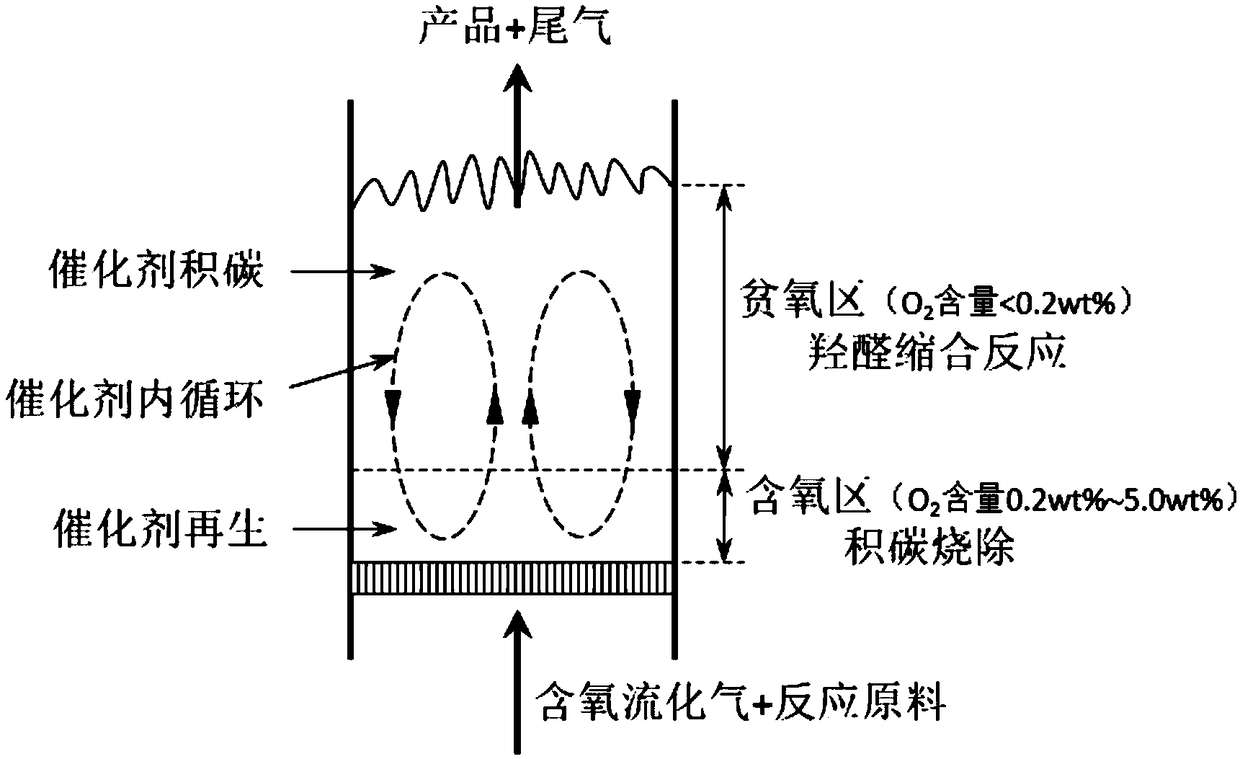

A technology of methyl methacrylate and methyl propionate, which is applied in the field of methyl methacrylate condensation between methyl propionate and formaldehyde aldol, can solve the problems of catalyst carbon deposition and deactivation, and achieve the enhancement of reaction regeneration process, The effect of convenient operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

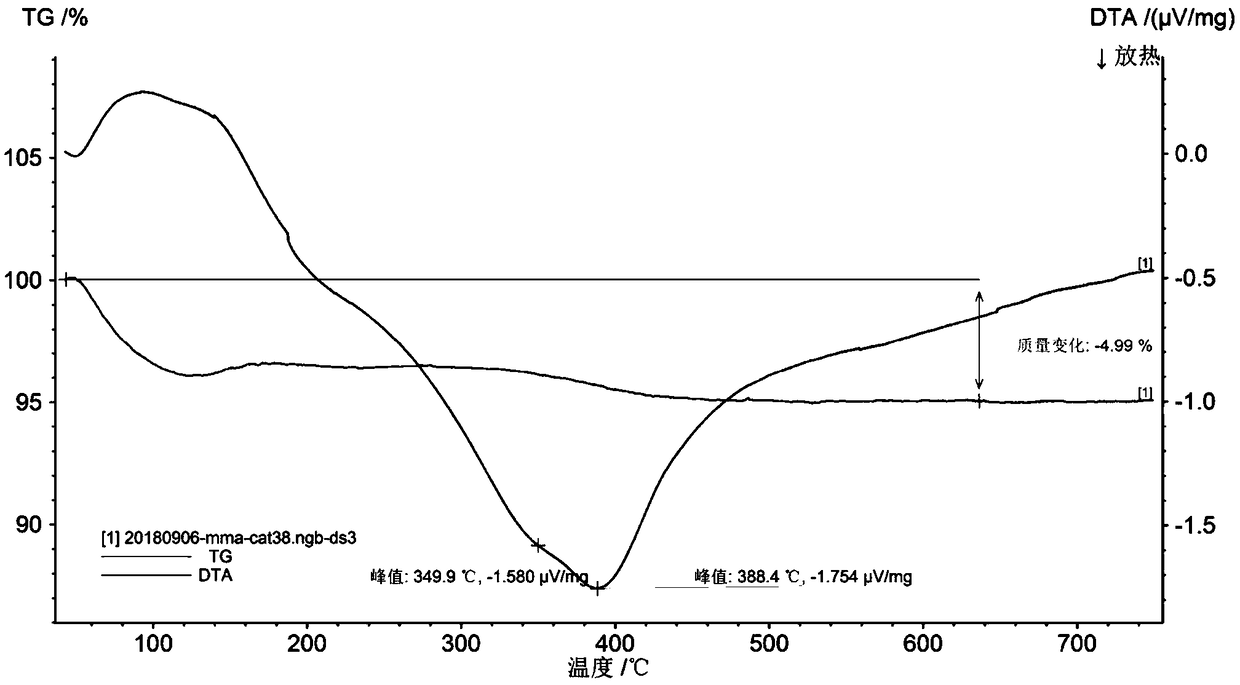

[0028] The catalyst in this example is a silica carrier loaded with cesium and zirconium, the cesium loading is 10wt%, and the zirconium loading is 1wt%. Loaded on a silica carrier by the method, dried at 105°C for 5 hours, and calcined at 550°C for 5 hours to obtain a catalyst with a particle size of 0.10-0.15mm.

[0029] Experimental process: Catalyst performance evaluation was carried out in an internal circulating fluidized bed reactor. The diameter of the fluidized bed reactor was 25mm, the height was 500mm, and the catalyst loading was 10g. The thermocouple was extended to the middle of the fluidized bed material to monitor the reaction temperature in real time. The distributor distributes the air evenly. Feedstock flow rate 0.4mL / min, containing 44wt% methyl propionate, 43wt% methanol, 10wt% formaldehyde and 3wt% water, oxygen-containing fluidizing gas containing 2wt% O 2 N 2 +O 2 Mixed gas, the flow rate is 50L / h, the reaction temperature is 360°C, and the operation...

Embodiment 2

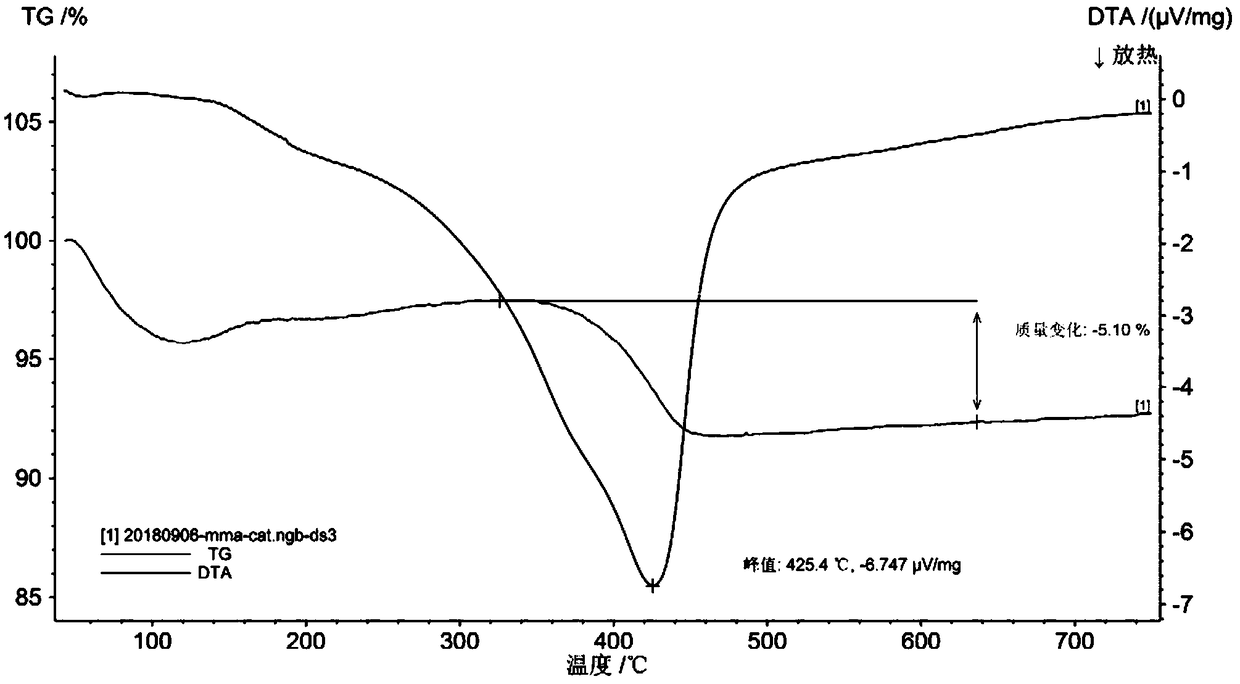

[0035] The catalyst in this example is a silica carrier loaded with cesium and zirconium, the cesium loading is 10wt%, and the zirconium loading is 1wt%. Loaded on a silica carrier by method, dried at 105°C for 5h, and calcined at 550°C for 5h to obtain a catalyst with a particle size of 0.38-0.83mm.

[0036] Experimental process: Catalyst performance evaluation was carried out in a fixed-bed tubular reactor. The inner diameter of the reaction tube was 25mm, and the catalyst loading was 10g. It was used after dilution. The thermocouple was extended to the middle of the catalyst bed to monitor the reaction temperature in real time. The raw material flow rate is 0.4mL / min, including 44wt% methyl propionate, 43wt% methanol, 10wt% formaldehyde and 3wt% water, the flow rate of carrier gas N2 is 5L / h, the reaction temperature is 360°C, and the operation is under normal pressure. During the experiment, the raw material was preheated at 250°C and then entered the catalytic bed with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com