Divalent metal-base MIL-53 microporous material, and preparation method and application thereof

A microporous material and metal technology, applied in the field of +2-valent metal MIL-53 microporous material and its preparation, can solve the problems of poor adsorption selectivity and weak binding force, and achieve simple steps, good stability, and adsorption. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

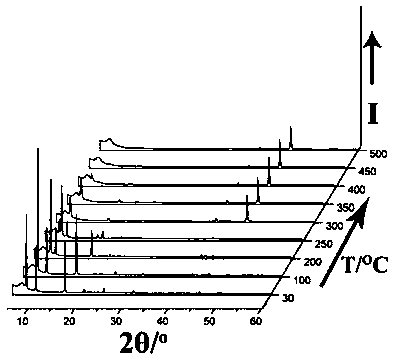

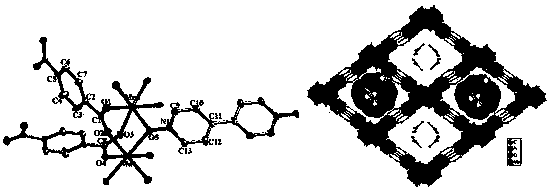

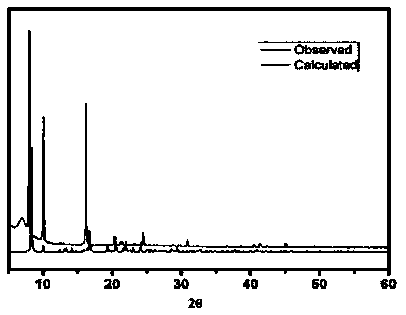

[0034] A preparation method based on +2 valent metal MIL-53 microporous material, the method is as follows:

[0035] Mn(NO 3 ) 2 solution (0.3 mmol, 0.0861g), H 2 BDC (0.1mmol, 0.0224g), bpdo (0.1mmol, 0.0188g) and DMF / H 2 O (3.0 ml: 1.0 ml) was placed in a small 25.0 ml beaker, and the resulting mixture was stirred at room temperature for one hour, and the resulting solution was transferred to a 17.0 ml stainless steel reaction vessel with a polytetrafluoroethylene liner, at 120 ° C for spontaneous pressure After heating for 10 hours under certain conditions, the reaction system was slowly cooled to room temperature to obtain red rod-shaped crystals and a very small amount of colorless block-shaped crystals. After the product was filtered and dried naturally, the colorless crystals could be removed manually. Finally, put the colorless solid product into a round-bottomed flask connected with an oil pump to evacuate, and heat in an oil bath at 150° C. for 8 hours to prepar...

Embodiment 2

[0037] A preparation method based on +2 valent metal MIL-53 microporous material, the method is as follows:

[0038] Mn(NO 3 ) 2 solution (0.1 mmol, 0.0287g), H 2 BDC (0.2 mmol, 0.0448g), bpdo (0.2mmol, 0.0376 g) and DMF / H 2 O (3.0 ml: 1.0 ml) was placed in a small 25.0 ml beaker, and the resulting mixture was stirred at room temperature for one hour, and the resulting solution was transferred to a 17.0 ml stainless steel reaction vessel with a polytetrafluoroethylene liner, at 120 ° C for spontaneous pressure After heating for 10 hours under certain conditions, the reaction system was slowly cooled to room temperature to obtain red rod-shaped crystals and a very small amount of colorless block-shaped crystals. After the product was filtered and dried naturally, the colorless crystals could be removed manually. Finally, put the colorless solid product into a round-bottomed flask connected with an oil pump to evacuate, and heat in an oil bath at 150° C. for 8 hours to prep...

Embodiment 3

[0040] A preparation method based on +2 valent metal MIL-53 microporous material, the method is as follows:

[0041] Mn(NO 3 ) 2 solution (0.5 mmol, 0.1435g), H 2 BDC (0.25mmol, 0.0560g), bpdo (0.25mmol, 0.0470g) and DMF / H 2 O (3.0 ml: 1.0 ml) was placed in a small 25.0 ml beaker, and the resulting mixture was stirred at room temperature for one hour, and the resulting solution was transferred to a 17.0 ml stainless steel reaction vessel with a polytetrafluoroethylene liner, at 120 ° C for spontaneous pressure After heating for 10 hours under certain conditions, the reaction system was slowly cooled to room temperature to obtain red rod-shaped crystals and a very small amount of colorless block-shaped crystals. After the product was filtered and dried naturally, the colorless crystals could be removed manually. Finally, put the colorless solid product into a round-bottomed flask connected with an oil pump to evacuate, and heat in an oil bath at 150° C. for 8 hours to prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com