Method for preparing high thermoelectric performance silver selenide/nylon flexible composite film

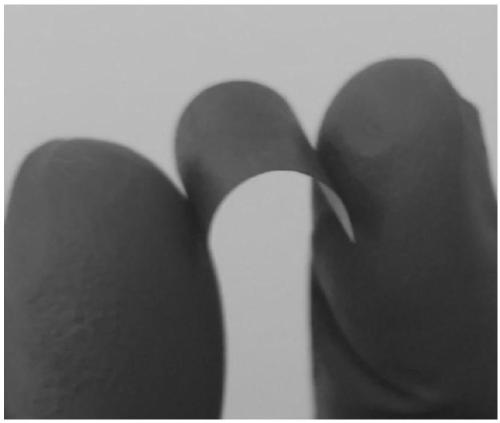

A thermoelectric performance, composite film technology, applied in the direction of coating, can solve problems such as limiting the application of flexible thermoelectric materials, and achieve the effect of performance improvement, strong bonding force, and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

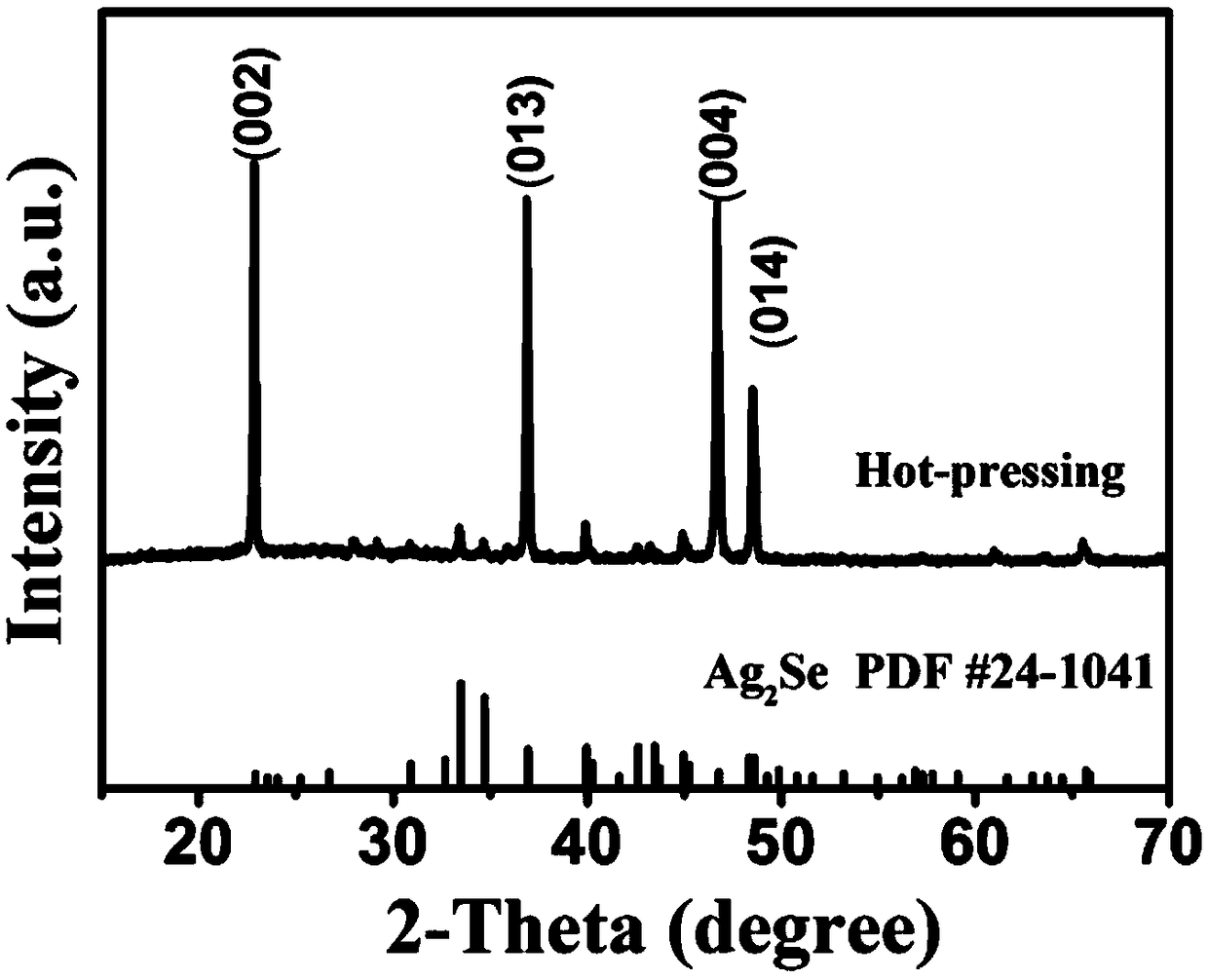

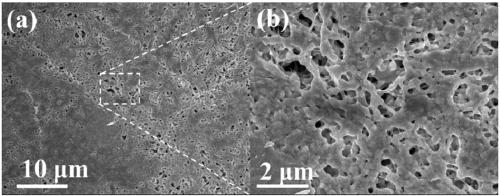

[0030] A preparation of high thermoelectric performance silver selenide (Ag 2 Se) / nylon flexible composite film method, the method will 20ml selenium nanowire (Se) ethylene glycol (EG) dispersion (45mmol / L), 0.6g silver nitrate (AgNO 3 ) and 80ml of ethylene glycol were added to the beaker, stirred at room temperature for 2 hours, centrifuged at a speed of 4000r / min, and the black precipitate was extracted, and deionized water and absolute ethanol were added alternately at a speed of 4000r / min. Remove impurities. After centrifugation, disperse the carefully cleaned black target product in 15ml of absolute ethanol for 30 minutes of ultrasonic dispersion, and then use nylon filter membrane as a substrate to obtain a silver selenide / nylon flexible membrane by vacuum filtration. The obtained membrane Dry in a vacuum oven at 60°C for 12 hours. After taking out the film, it is hot-pressed, 200℃, 1MPa hot-pressed for 30min, the conductivity can be obtained: ~497S / cm, Seebeck coeffic...

Embodiment 2

[0032] A preparation of high thermoelectric performance silver selenide (Ag 2 Se) / nylon flexible composite film method, the method will 20ml selenium nanowire (Se) ethylene glycol (EG) dispersion (45mmol / L), 0.6g silver nitrate (AgNO 3 ) and 80ml of ethylene glycol were added to the beaker, stirred at room temperature for 2 hours, centrifuged at a speed of 4000r / min, and the black precipitate was extracted, and deionized water and absolute ethanol were added alternately at a speed of 4000r / min. Remove impurities. After centrifugation, disperse the carefully cleaned black target product in 15ml of absolute ethanol for 30 minutes of ultrasonic dispersion, and then use nylon filter membrane as a substrate to obtain a silver selenide / nylon flexible membrane by vacuum filtration. The obtained membrane Dry in a vacuum oven at 60°C for 12 hours. Available conductivity: ~202S / cm, Seebeck coefficient -75.5μV K -1 , power factor is about 115μW m -1 K -2 silver selenide / nylon flexibl...

Embodiment 3

[0034] A method for preparing silver selenide / nylon flexible composite film with high thermoelectric performance, the method is ethylene glycol (EG) dispersion (45mmol / L) of 20ml selenium nanowire (Se), 0.3g silver nitrate (AgNO 3) and 80ml of ethylene glycol were added to the beaker, stirred at room temperature for 4 hours, centrifuged at a speed of 4000r / min, and the black precipitate was extracted, and deionized water and absolute ethanol were added alternately and washed by centrifugation at a speed of 4000r / min for 5min. Remove impurities. After centrifugation, disperse the carefully cleaned black target product in 15ml of absolute ethanol for 30 minutes of ultrasonic dispersion, and then use nylon filter membrane as a substrate to obtain a silver selenide / nylon flexible membrane by vacuum filtration. The obtained membrane Dry in a vacuum oven at 60°C for 12 hours. After the film is taken out, it is hot-pressed at 200°C and 4MPa for 30 minutes, and the power factor can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com