Self-cleaning water-based UV ultraviolet curing varnish and preparation method thereof

An ultraviolet light and self-cleaning technology, applied in the field of chemical materials, can solve problems such as easy yellowing, difficult to clean, low performance, etc., and achieve the effect of good wear resistance, easy cleaning, uniform and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

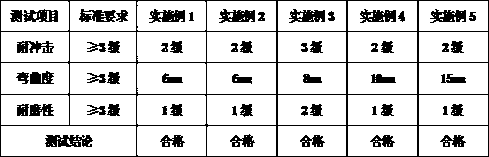

Examples

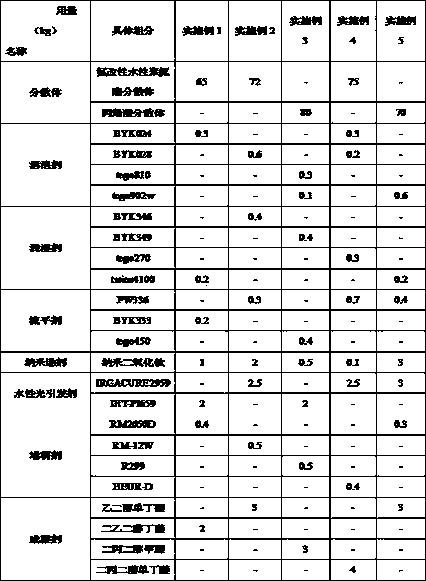

Embodiment 1

[0056] This example provides a self-cleaning nanometer water-based UV UV curable varnish. The specific preparation process is as follows: first pour 65kg of fluorine-modified water-based polyurethane dispersion BER101 into the dispersion kettle, then pour 0.3kg of defoamer BYK024, 0.2kg Wetting agent twins4100, 0.2kg leveling agent BYK333 are pre-mixed evenly, and slowly added to the dispersion container under stirring, slowly adding 1kg of nano-titanium dioxide, adding 0.4kg of thickener RM2050D to adjust to a suitable viscosity, and dispersing at high speed for 15 minutes , use a 100μm fineness meter to check that the fineness is qualified and there is no oil shrinkage, then slowly add 2kg of water-based photoinitiator IHT-PI659 dissolved with 2kg of film-forming agent dipropylene glycol butyl ether DPNB, and disperse at a medium speed (1500 rpm / Minutes or more) for 10-15 minutes, use a 100μm fineness meter to check the fineness and no oil shrinkage, add 28.9kg of deionized ...

Embodiment 2

[0058] This example provides a self-cleaning nanometer water-based UV UV curable varnish. The specific preparation process is as follows: first pour 72kg of fluorine-modified water-based polyurethane dispersion BET101 into the dispersion kettle, then pour 0.6kg of defoamer BYK028, 0.4kg Wetting agent BYK346 and 0.3kg leveling agent BYK336 are pre-mixed evenly, and slowly added to the dispersion container under stirring, slowly adding 2kg of nano-titanium dioxide, adding 0.5kg of thickener RM-12W to adjust to a suitable viscosity, and then dispersing at a high speed After 15 minutes, use a 100μm fineness meter to check that the fineness is qualified and there is no oil shrinkage, then slowly add 2.5kg of water-based photoinitiator IRGACURE2959 dissolved in 3kg of film-forming agent ethylene glycol monobutyl ether, and disperse at a medium speed ( 1500 rpm or more) for 10-15 minutes, use a 100μm fineness meter to check that the fineness is qualified and there is no oil shrinkage,...

Embodiment 3

[0060] This embodiment provides a self-cleaning nanometer water-based UV UV curable varnish, and its specific preparation process is as follows: first pour 80kg of acrylic acid dispersion into the dispersion kettle, and 0.4kg of defoamer, wherein 0.3kg of defoamer tego810 and 0.1kg defoamer tego902w, 0.4kg wetting agent BYK349, 0.4kg leveling agent tego450 are pre-mixed evenly, slowly added to the dispersion container under stirring, slowly added 0.5kg nano-titanium dioxide, and 0.5kg thickener R299 After adjusting to a suitable viscosity, disperse at high speed for 15 minutes, use a 100μm fineness meter to check that the fineness is qualified and there is no oil shrinkage, after dissolving 2kg of water-based photoinitiator IHT-PI659 with 3kg of film-forming agent dipropylene glycol methyl ether Add slowly, disperse at a medium speed (above 1500 rpm) for 10-15 minutes, use a 100μm fineness meter to check that the fineness is qualified and there is no oil shrinkage, add 11.9kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com