Fruit wine filtration technology

A fruit wine and process technology, applied in the field of fruit wine filtration technology, can solve the problems of poor impurity removal effect, dilute fruit wine flavor, unstable wine body, etc., and achieve the effects of preventing lightening, unique flavor and excellent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

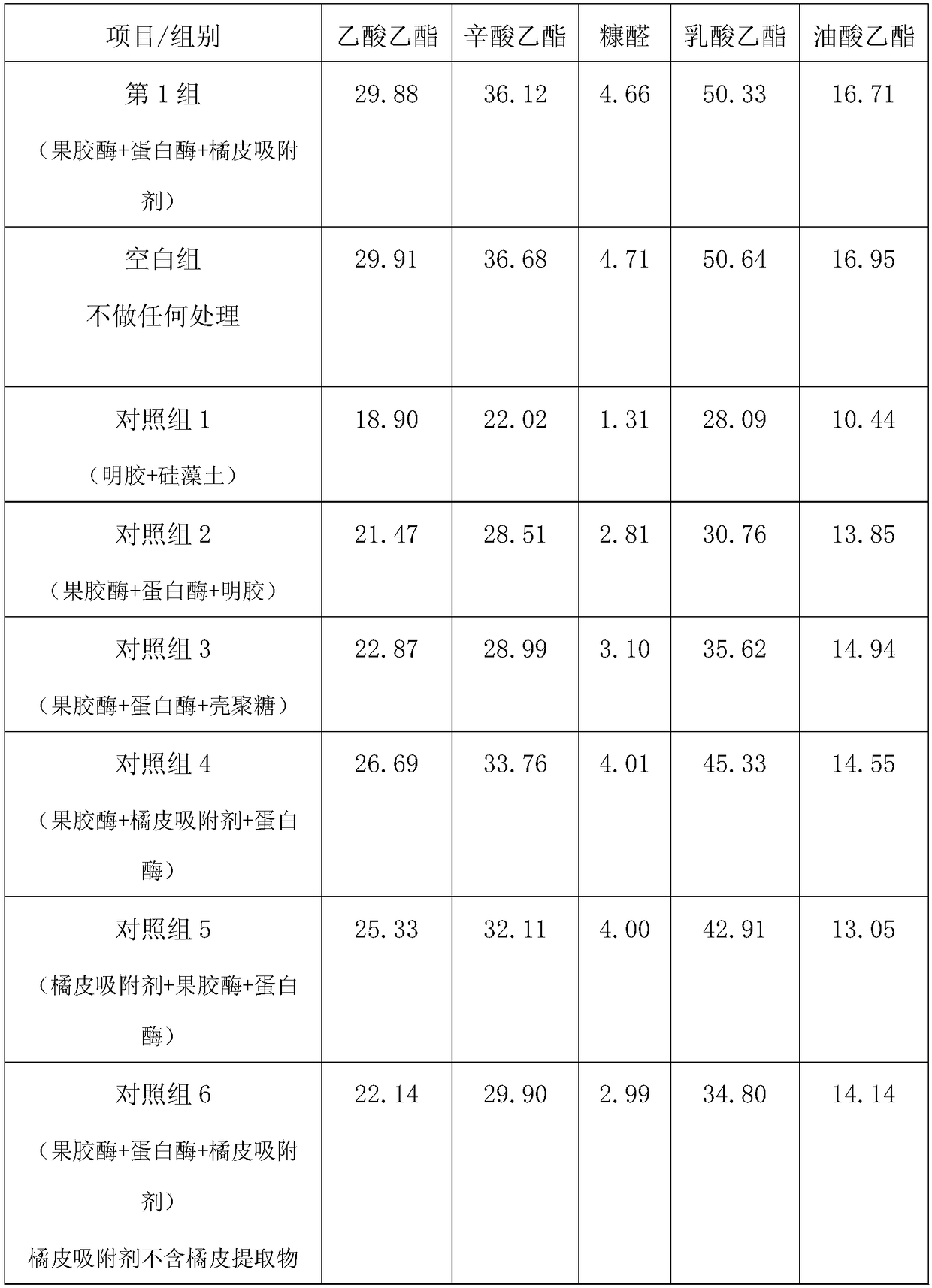

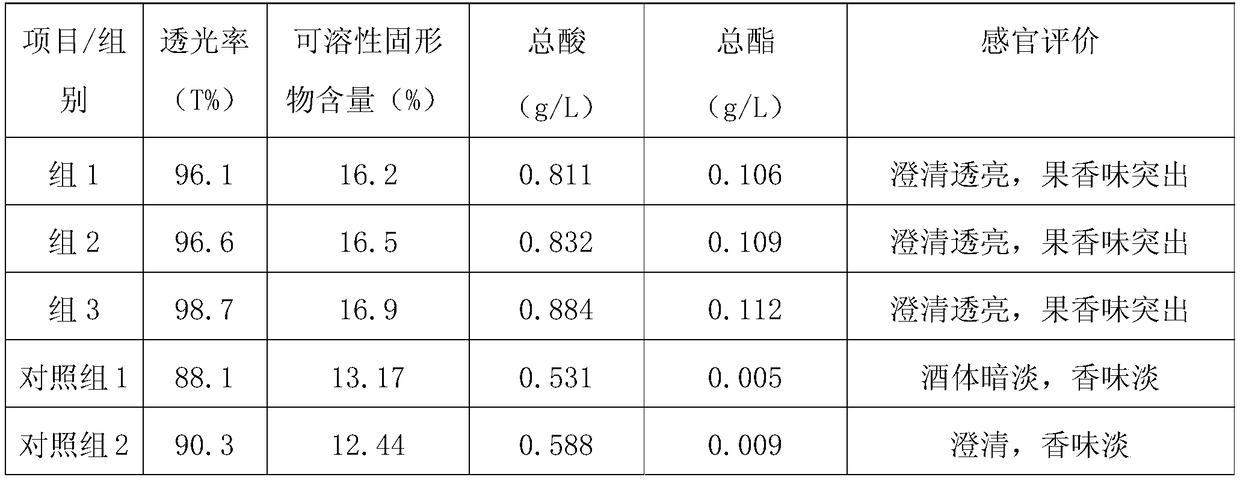

Examples

Embodiment 1

[0017] This embodiment is a kind of filtration process of fruit wine. First, add pectinase with a weight of 0.01‰ of the fruit wine to the fruit wine, the enzyme activity is 300U / g, and let it stand at a constant temperature for 1 hour at 35° C., inactivate the enzyme activity in a boiling water bath, and cool it. Then add the protease with the weight of 0.005‰ of the fruit wine, the enzyme activity is 200U / g, let it stand at a constant temperature at 45°C for 1h, inactivate the enzyme activity in a boiling water bath, cool, then add the orange peel adsorbent, the addition amount is 1g / L, shake 20min, let stand at 5°C for 1 day, centrifuge at 2000r / min for 15min to remove the precipitate, and finally filter the upper liquor with a microporous membrane with a pore size of 0.2μm to obtain a stable and clear fruit wine.

[0018] The preparation method of the orange peel adsorbent is as follows: put the citrus peel in a retort and carbonize it at 300° C. for 30 minutes, cool to obt...

Embodiment 2

[0021] In this embodiment, a kind of filtration process of fruit wine, firstly add pectinase with the weight of 0.03‰ of the fruit wine to the fruit wine, the enzyme activity is 400U / g, let it stand at a constant temperature at 45°C for 3 hours, inactivate the enzyme activity in a boiling water bath, cool, Then add protease with the weight of 0.02‰ of the fruit wine, the enzyme activity is 300U / g, let it stand at a constant temperature at 55°C for 2h, inactivate the enzyme activity in a boiling water bath, cool, then add orange peel adsorbent, the addition amount is 2g / L, shake After 30 minutes, stand at 15°C for 2 days, centrifuge at 3000r / min for 25 minutes to remove the precipitate, and finally filter the upper liquor with a microporous membrane with a pore size of 0.4μm to obtain a stable and clear fruit wine.

[0022] The preparation method of the orange peel adsorbent is as follows: put the citrus peel into a retort and carbonize at 400° C. for 50 minutes, cool to obtain ...

Embodiment 3

[0025] This embodiment is a kind of filtration process of fruit wine. First, add pectinase with a weight of 0.02‰ of the fruit wine to the fruit wine, the enzyme activity is 350U / g, and stand at a constant temperature at 40°C for 2h, inactivate the enzyme activity in a boiling water bath, and cool. Then add the protease with the weight of 0.01‰ of the fruit wine, the enzyme activity is 240U / g, stand at a constant temperature at 50°C for 1.5h, inactivate the enzyme activity in a boiling water bath, cool, then add orange peel adsorbent, the addition amount is 1.5g / L , shake for 25 minutes, stand at 8°C for 1.5 days, centrifuge at 2800r / min for 20 minutes to remove the precipitate, and finally filter the upper liquor with a microporous membrane with a pore size of 0.3μm to obtain a stable and clear fruit wine.

[0026] The preparation method of the orange peel adsorbent is as follows: put the citrus peel in a retort and carbonize it at 350° C. for 40 minutes, cool to obtain the or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com