Method for preparing iron-aluminum hydrotalcite through sacrificial anode method

A sacrificial anode, hydrotalcite technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of forming influence, forming other products, unable to obtain Fe/Al-LDHs, etc., achieving mild reaction, simple operation, easy to save energy The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

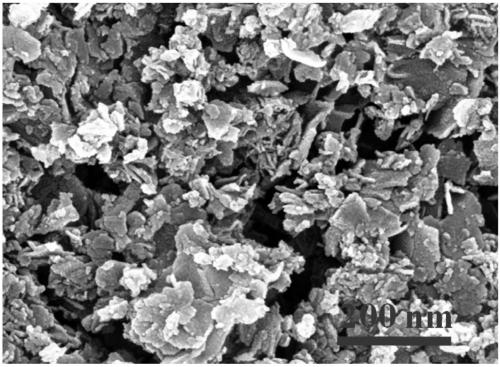

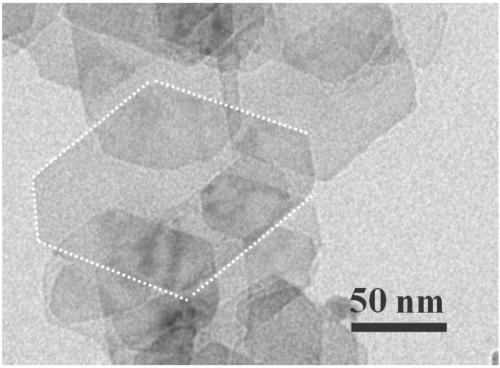

Image

Examples

Embodiment 1

[0025] A kind of sacrificial anode one-step method for preparing Fe / Al-LDHs, comprises the following steps:

[0026] 1) Completely dissolve the electrolyte (sodium sulfate, sodium chloride or sodium bicarbonate) in water so that the electrolyte concentration is 1-2g / L to obtain an electrolyte solution;

[0027] 2) Connect the iron metal electrode and the aluminum metal electrode to bipolar or monopolar connection, place them in the electrolytic cell, and connect them to a DC power supply;

[0028] 3) Add the electrolyte solution in step 1) into the electrolytic cell, and fully stir evenly, then turn on the power, and carry out the electrolytic reaction for 10-60 minutes;

[0029] 4) After the electrolysis is completed, pour the solution in step 3) into the sedimentation tank, let it stand for 10-60min, and then control the rotation speed to be 1000-6000r / min for centrifugation for 3min, and wash the floc precipitate with water for 3-5 times, then Put it in a freeze dryer and ...

Embodiment 2

[0038] A preparation method for one-step synthesis of Fe / Al-LDHs material by a sacrificial anode method, specifically comprising:

[0039] 1) Dissolve the electrolyte sodium sulfate in water, and dissolve completely, and its concentration is 1-2g / L;

[0040] 2) Two DC power supplies are used to respectively control the magnitude of the current during electrolysis of two metal plates (two iron and aluminum plates). Connected state, during the electrolysis process, the current density is 5-50A / m 2 , and the current ratio of iron and aluminum electrodes is controlled to be 2:3-2:1, and the ratio of iron ions and aluminum ions to be electrolyzed is 1-3;

[0041] 3) Pour the electrolytic solution obtained in the above 1) into the reaction device described in 2), turn on the power supply, and the current density during the electrolysis process is 5-50A / m 2 Fully stir evenly, react for 10-60 minutes, the length of electrolysis time determines the amount of electrolytic metal;

[0...

Embodiment 3

[0053] A preparation method for one-step synthesis of Fe / Al-LDHs material by a sacrificial anode method, specifically comprising:

[0054] 1) Dissolve the sodium chloride electrolyte in water, and dissolve it completely, and its concentration is 1-2g / L;

[0055] 2) Only one DC power supply is used to control the magnitude of the output current during the electrolysis process of two metals (two pieces of iron and aluminum). electrode, the cathode is connected to the aluminum electrode), the current density is 5-50A / m 2 , the electrode spacing is 1-3cm, and the bottom of the electrolytic cell needs to be kept connected;

[0056] 3) Pour the electrolytic solution obtained in the above 1) into the reaction device described in 2), turn on the power supply, and the current density during the electrolysis process is 5-50A / m 2 Fully stir evenly, react for 10-60 minutes, the length of electrolysis time determines the amount of electrolytic metal;

[0057] 4) After the electrolysis i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com