Modifying method for polyamide film composite film, polyamide film composite film and application thereof

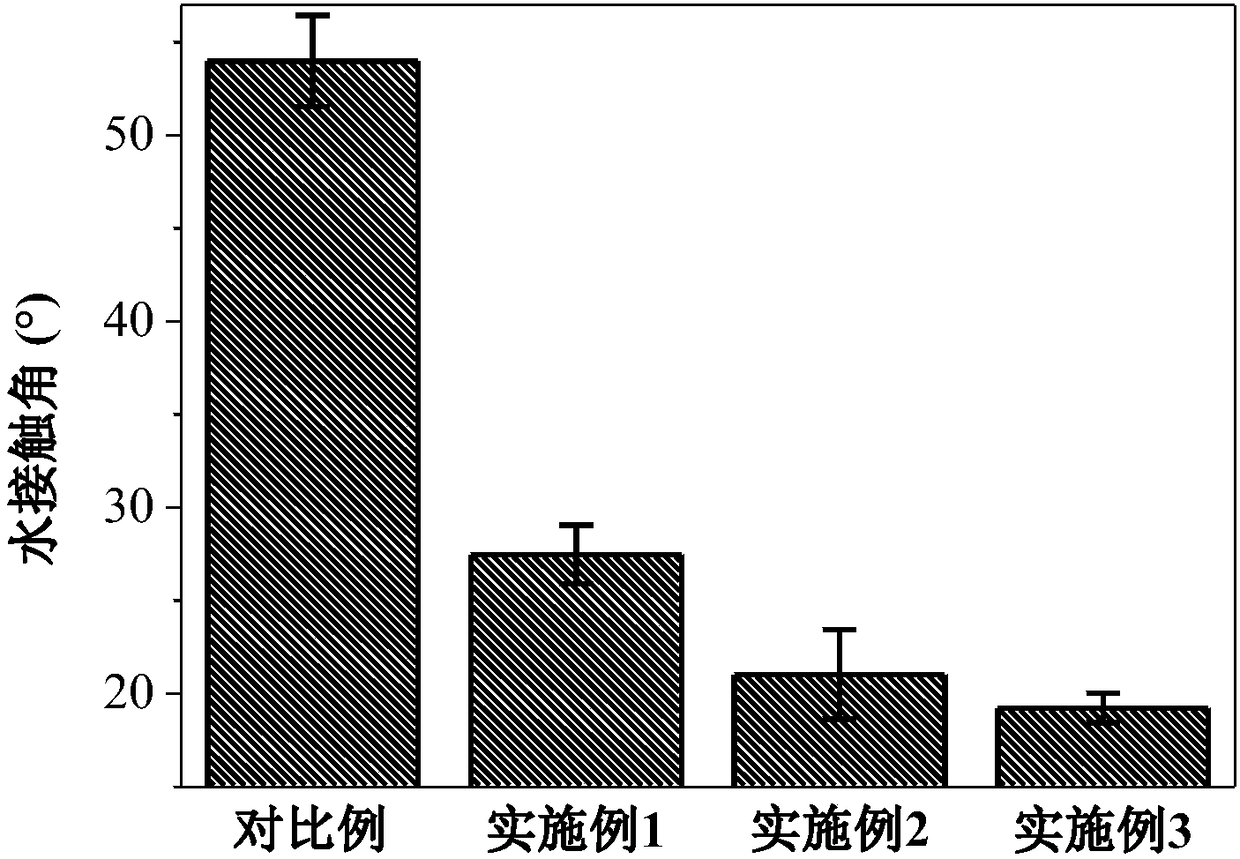

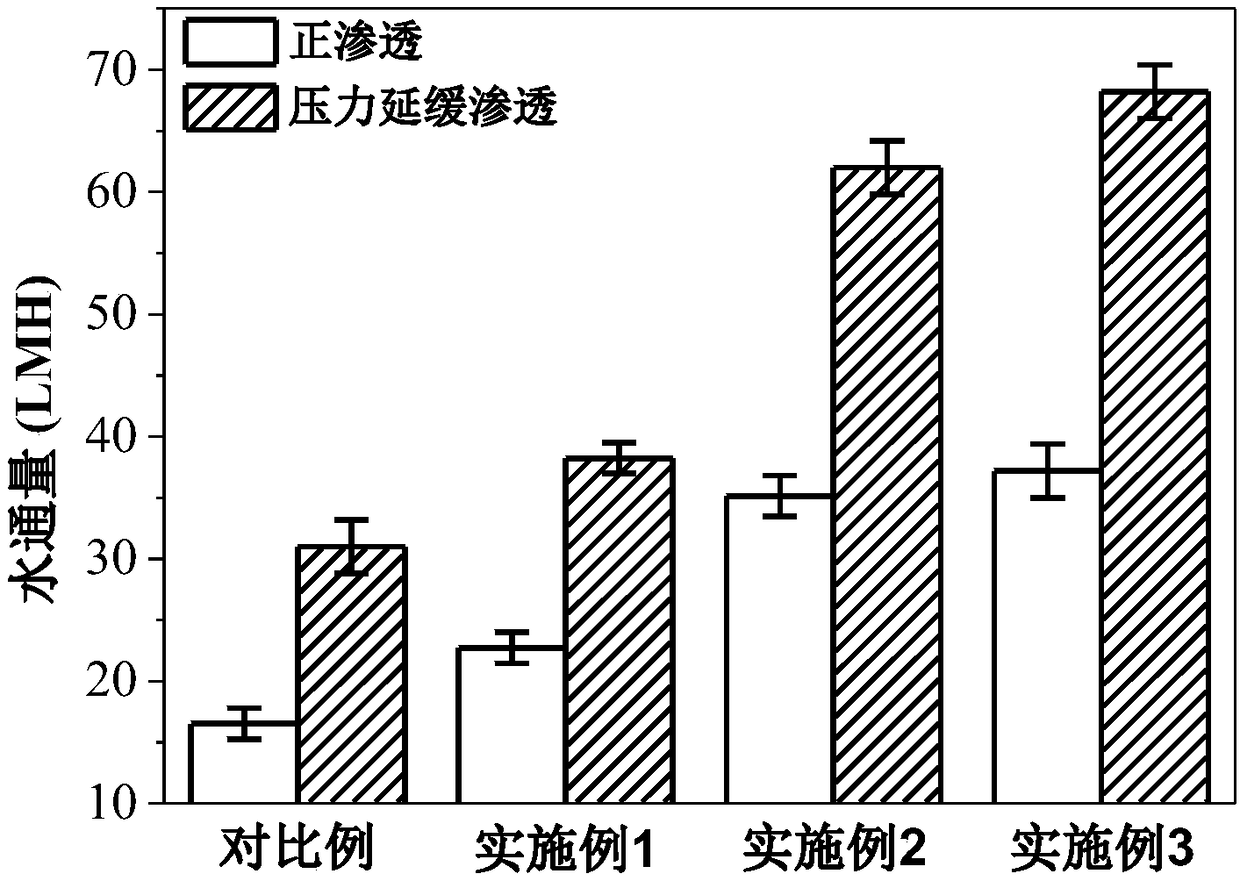

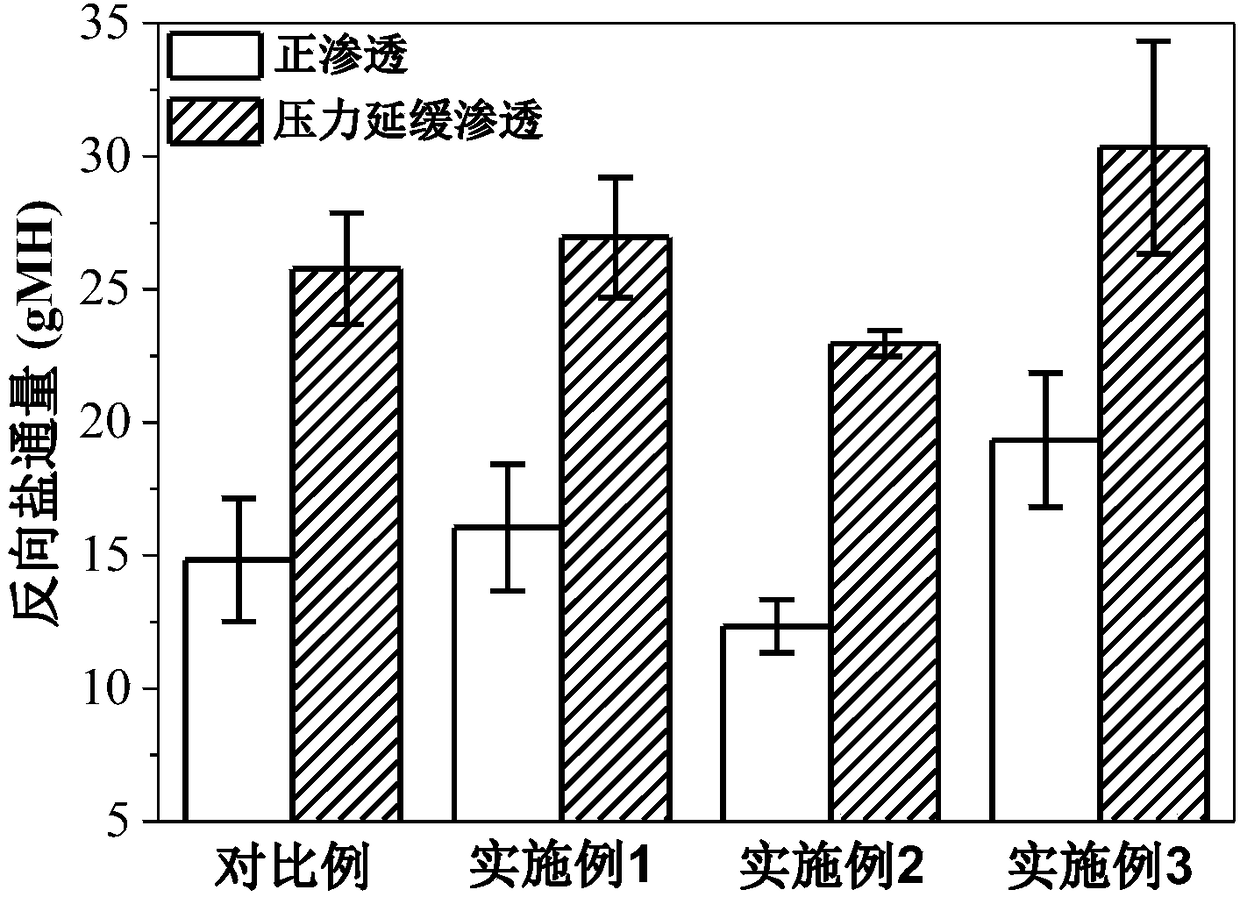

A polyamide film and composite membrane technology, applied in the field of membrane separation, can solve the problems of low water flux, high membrane fouling tendency, and low reverse salt flux of polyamide thin film composite membranes, and achieve antibacterial and membrane fouling tendency. Low contamination tendency and low reverse salt flux effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The polymer support layer of the composite membrane in Example 1 is a polysulfone microfiltration membrane. The preparation process of the composite membrane includes the following steps

[0061] (1) Prepare an aqueous phase solution, which contains 3.4% m-phenylenediamine polyamine in mass fraction. An organic phase solution of polybasic acid chlorides is prepared, and the solution uses n-hexane as a solvent and 0.15% of trimesoyl chloride as a solute in mass / volume fraction. The polysulfone-based membrane was completely soaked in the aqueous phase solution for 2 minutes and then taken out.

[0062] (2) After removing the excess aqueous phase solution on the surface, pour the organic phase solution on the upper surface of the wetted polysulfone membrane, and pour off the excess organic phase solution after 1 minute of contact time. The interfacial polymerization reaction between the amine monomer and the acid chloride monomer occurs at the interface of the two phases...

Embodiment 2

[0065] The polymer support layer of the composite membrane in Example 2 is a polysulfone microfiltration membrane. The preparation process of the composite membrane includes the following steps

[0066] (1) Prepare an aqueous phase solution, which contains 3.4% m-phenylenediamine polyamine in mass fraction. An organic phase solution of polybasic acid chlorides is prepared, and the solution uses n-hexane as a solvent and 0.15% of trimesoyl chloride as a solute in mass / volume fraction. The polysulfone-based membrane was completely soaked in the aqueous phase solution for 2 minutes and then taken out.

[0067] (2) After removing the excess aqueous phase solution on the surface, pour the organic phase solution on the upper surface of the wetted polysulfone membrane, and pour off the excess organic phase solution after 1 minute of contact time. The interfacial polymerization reaction between the amine monomer and the acid chloride monomer occurs at the interface of the two phas...

Embodiment 3

[0071] The polymer support layer of the composite membrane in Example 3 is a polysulfone microfiltration membrane. The preparation process of the composite membrane includes the following steps

[0072] (1) Prepare an aqueous phase solution, which contains 3.4% m-phenylenediamine polyamine in mass fraction. An organic phase solution of polybasic acid chlorides is prepared, and the solution uses n-hexane as a solvent and 0.15% of trimesoyl chloride as a solute in mass / volume fraction. The polysulfone-based membrane was completely soaked in the aqueous phase solution for 2 minutes and then taken out.

[0073] (2) After removing the excess aqueous phase solution on the surface, pour the organic phase solution on the upper surface of the wetted polysulfone membrane, and pour off the excess organic phase solution after 1 minute of contact time. The interfacial polymerization reaction between the amine monomer and the acid chloride monomer occurs at the interface of the two phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com