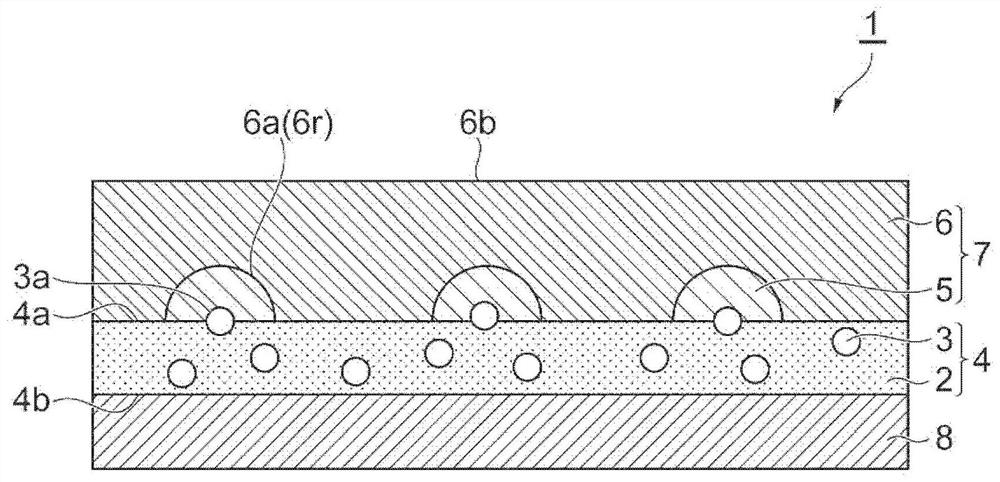

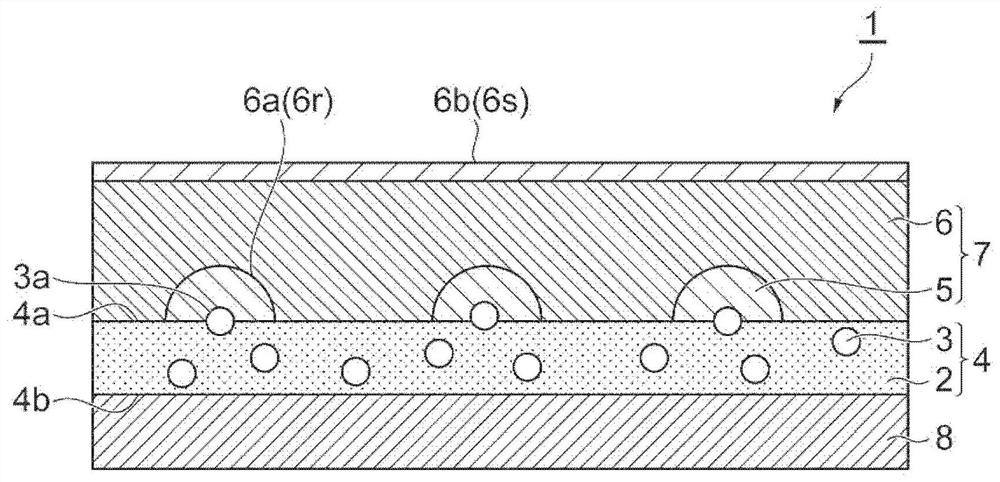

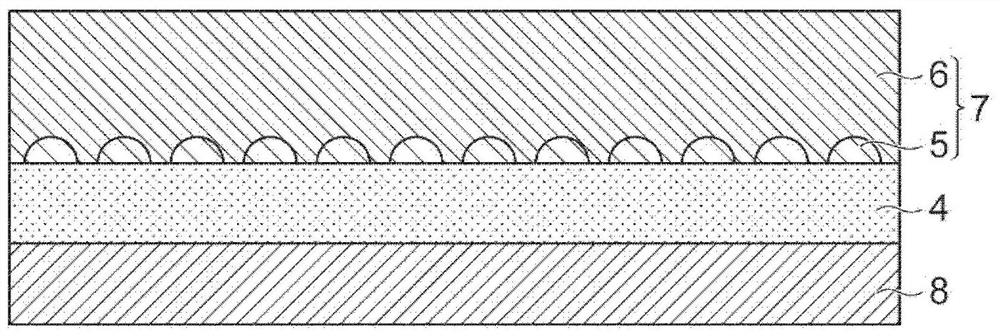

Sheet, metal mesh and method of manufacture

A metal mesh and sheet technology, applied in the fields of printed circuit manufacturing, metal layered products, chemical instruments and methods, etc., can solve the problems of invisibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] 1.5 mmol of anionic surfactant PELEX OT-P (manufactured by Kao Corporation, trade name), 50 ml of toluene, and 100 ml of ion-exchanged water were added, and the mixture was kept at 20°C with stirring to obtain an emulsion. 21.2 mmol of pyrrole monomer was added to the obtained emulsion, and after stirring for 1 hour, 6 mmol of ammonium persulfate was added and polymerization reaction was performed for 2 hours. After the reaction, the organic layer was recovered and washed several times with ion-exchanged water to obtain polypyrrole particles having an average particle diameter of 40 nm dispersed in toluene.

[0090] Add 5 parts by mass of binder SUPER BECKAMINE J-820 (manufactured by DIC Corporation, trade name) to 1 part by mass of the obtained polypyrrole particles to prepare a resin composition (mass ratio of binder to polypyrrole particles =5:1). The obtained resin composition was coated on a PET film (manufactured by Toyobo Co., Ltd., trade name: COSMOSHINE A4100)...

Embodiment 2

[0093] A sheet was obtained in the same manner as in Example 1 except that the time for immersion in the electroless plating solution tank containing nickel ions was set to 30 seconds.

Embodiment 3

[0095] A sheet was obtained in the same manner as in Example 1 except that the time for immersion in the electroless plating bath containing nickel ions was set to 40 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com