MOFs material as well as preparation method and use thereof

A technology of substrates and metal organic frameworks, applied in the field of materials, can solve problems such as poor compatibility, affecting membrane separation performance, and pore clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The second aspect of the present invention provides the preparation method of described MOFs material, comprising:

[0036] Obtaining a metal-organic framework substrate comprising grafted groups;

[0037] At least part of the grafting group is grafted to the linear polymer.

[0038] In the preparation method of the MOFs material provided by the present invention, the method of grafting the grafting group to the linear polymer can be grafting from the surface of the MOF (Grafting from). For example, two or more polycondensed monomers can be directly mixed with MOFs, and polycondensed polymer brushes can be grown from the surface of MOFs through covalent links. Polycondensed polymers can include but are not limited to polyamide, polyimide, polysulfone, One or more combinations of polyethersulfone, etc. For another example, free radical initiating groups can be reacted on the amino groups on the surface of MOFs, and free radical polymerization polymers can be grown thro...

Embodiment 1

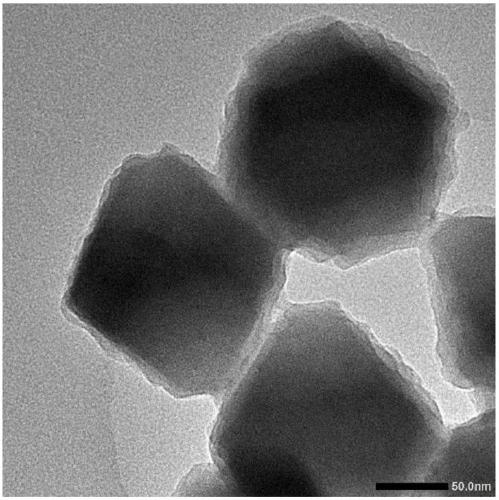

[0049] Preparation of MOFs particles:

[0050] The metal salt solution and the ligand solution were dissolved in DMF solution, and monodisperse MOFs were synthesized by heating.

[0051] The metal salt is 13 parts (parts by weight, the same below) of zirconium chloride, 10 parts of 2-aminoterephthalic acid is selected as the ligand, 3032 parts of solvent DMF, the heating temperature is 120 ° C, and the reaction time is 20 hours to obtain UiO- 66-NH 2 nanoparticles.

[0052] The surface of MOFs particles is connected with covalently connected linear polymers, and the preparation method is as follows:

[0053] Take 2 parts of UiO-66-NH prepared above 2 Nanoparticles, dispersed in 17 parts of DMF, then add 3 parts of 2,4,6-trimethyl-1,3-phenylenediamine (DAM), stir with a magnetic stirrer until DAM is completely dissolved, the stirring speed is 800 rpm / min, add 3 parts of 4,4′-diphenyl ether dianhydride (ODPA) under the protection of nitrogen, and then add 17 parts of DMF, a...

Embodiment 2

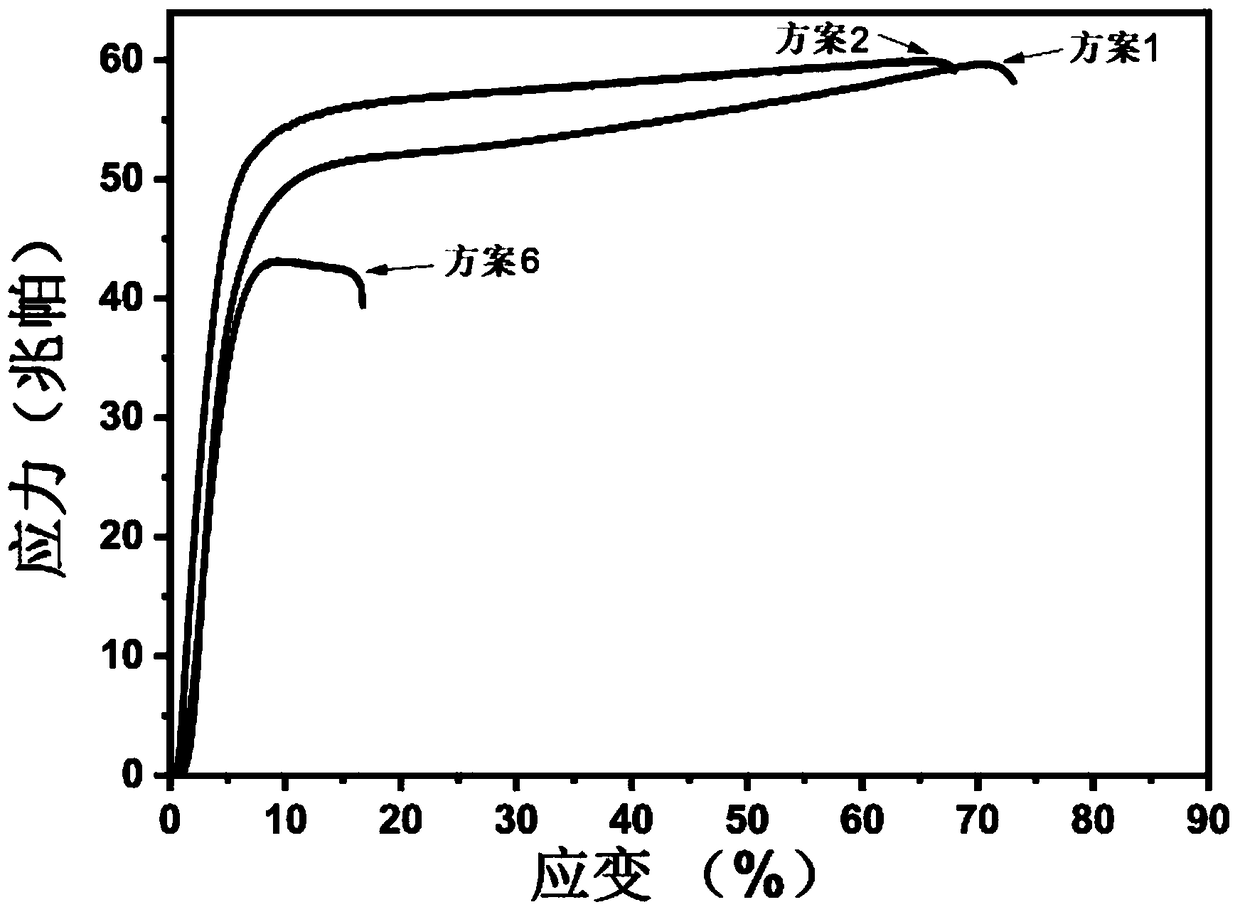

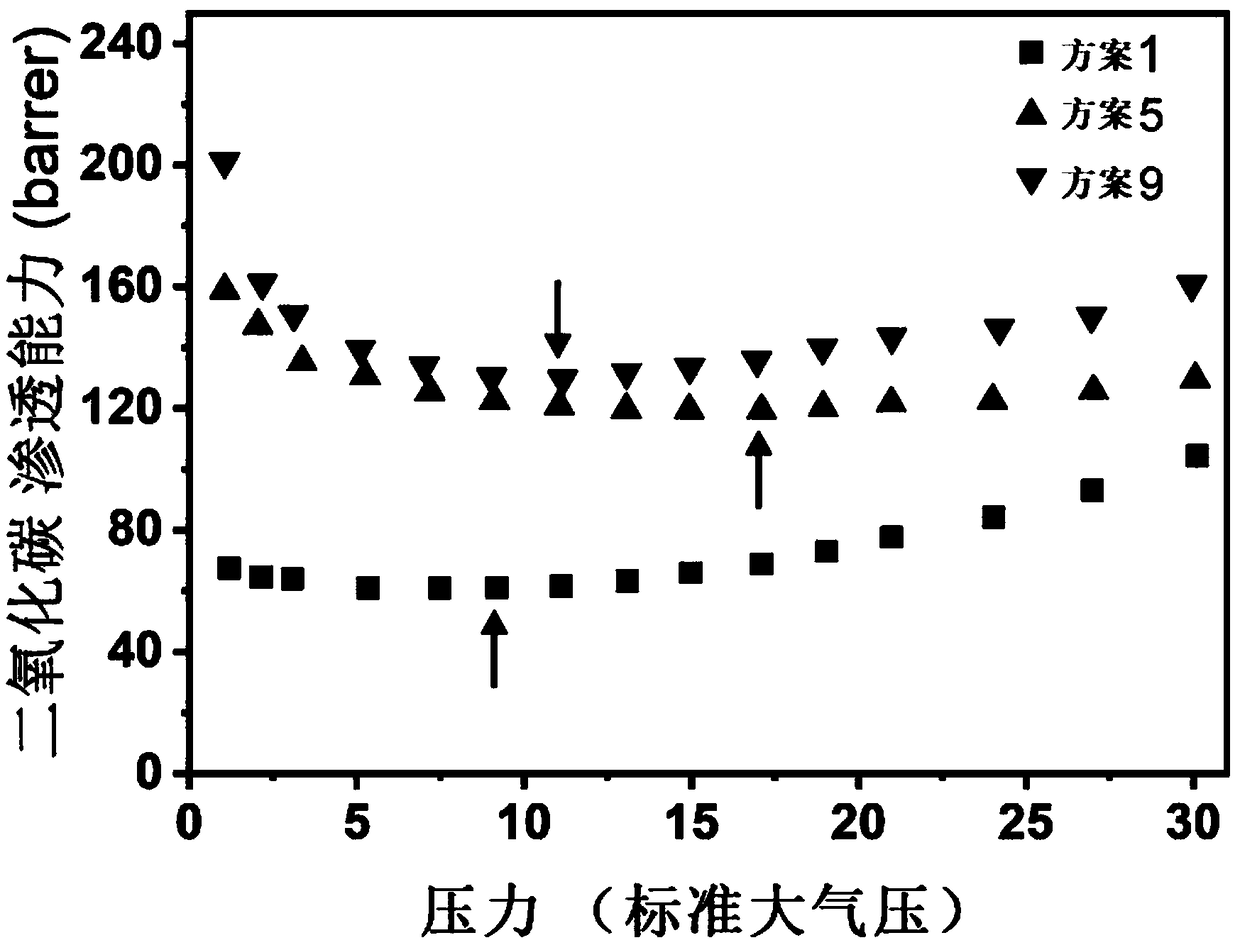

[0057] plan 1:

[0058] The polyimide was made into a 3wt% dichloromethane solution. Take the prepared polymer solution and add it to a glass container, cover it with aluminum foil, and let the solution evaporate slowly at room temperature. After the solvent was completely evaporated, the film was placed in a vacuum drying oven at 100°C for vacuum drying.

[0059] Scenario 2:

[0060] Take 5 parts of UiO-66-NH with surface grafted polymer 2 (prepared in Example 1), 95 parts of polyimide macromolecules, 950 parts of methylene chloride, mix uniformly with ultrasonic waves, join the mixed solution prepared in the glass container, cover with aluminum foil, and make the solution slowly under normal temperature Volatile. After the solvent was completely evaporated, the film was placed in a vacuum drying oven at 100°C for vacuum drying.

[0061] Option 3:

[0062] Take 9 parts of UiO-66-NH with surface grafted polymer 2 (prepared in Example 1), 91 parts of polyimide macromolec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com